Single cell separation method based on droplet micro-fluidic chips

A microfluidic chip and single cell separation technology, applied in the field of microfluidic technology and cell biology, can solve the problems of cumbersome and complicated operation steps, low capture efficiency, cell damage, etc., and achieve a wide range of applications, less dosage, The effect of experimenting cheaply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

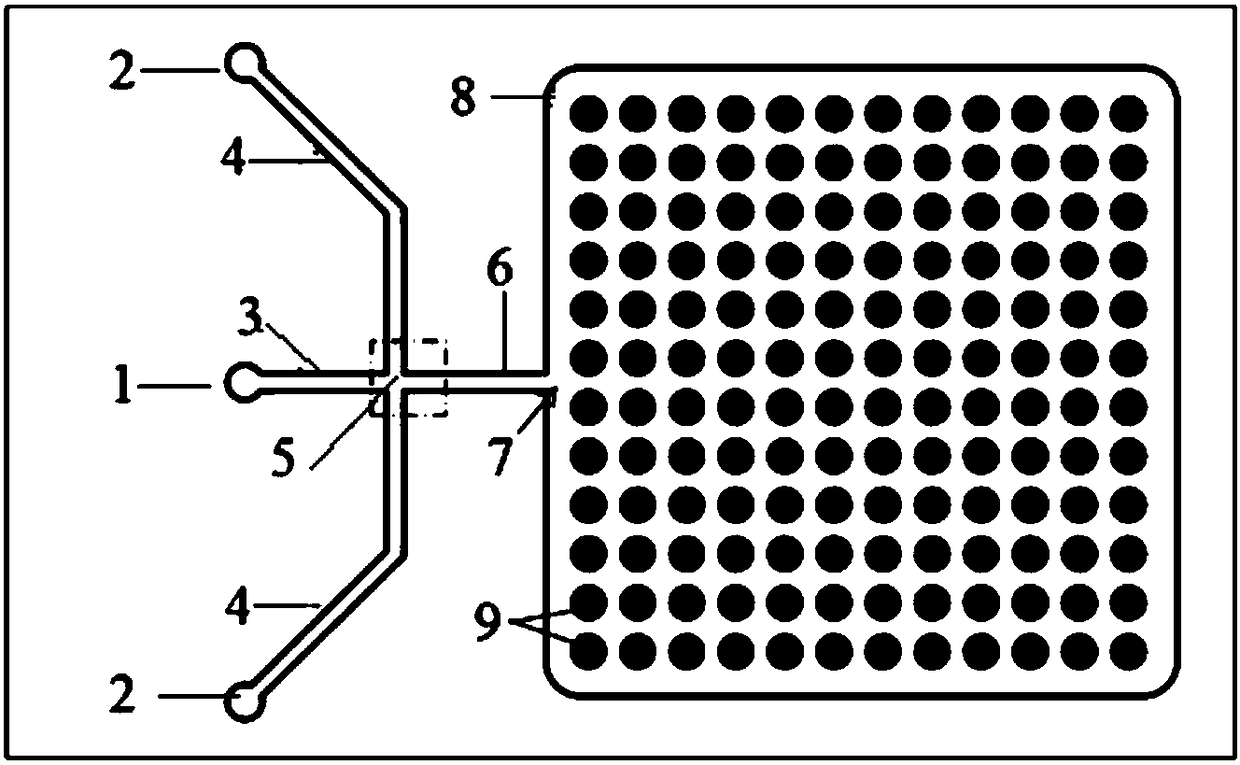

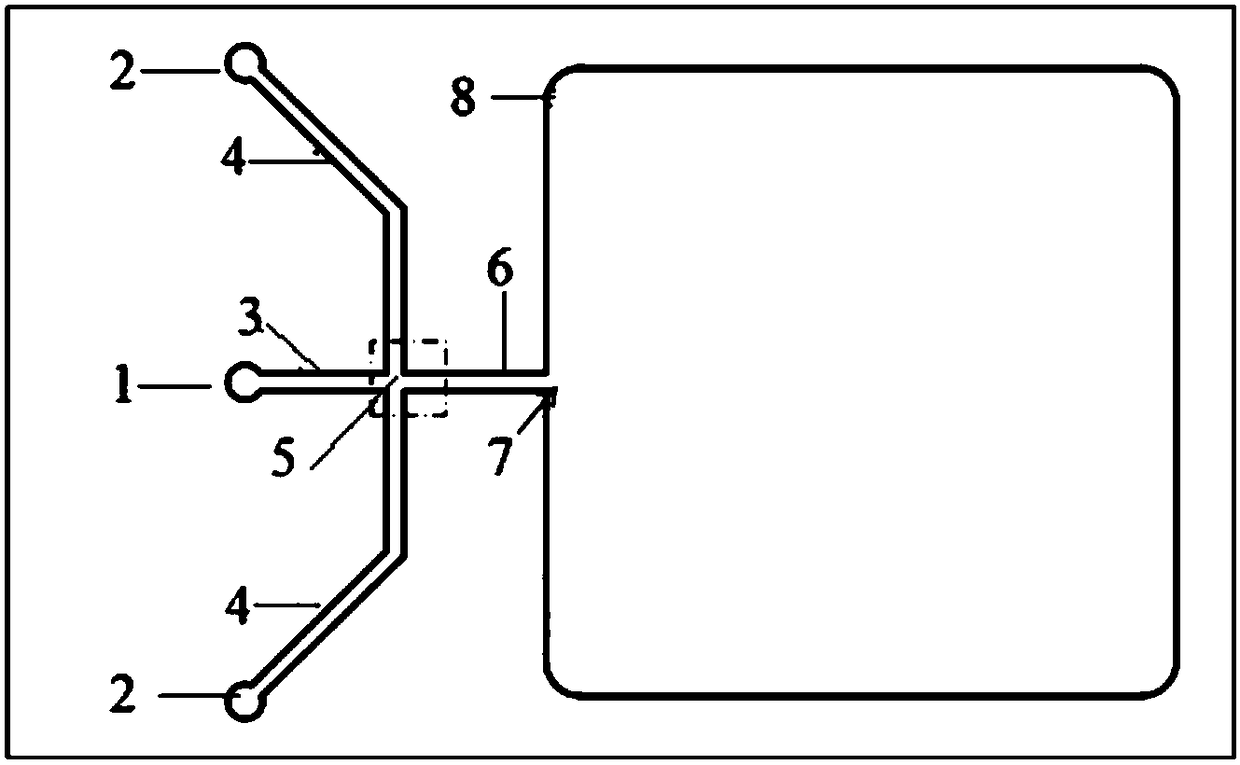

[0052] Preparation of a Droplet Microfluidic Chip for Single Cell Separation

[0053] Preparation of the superstructure SU-8 template of the chip: The microfluidic chip adopts photolithography and etching to prepare the SU-8 template with the channel part protruding; first, cast a layer of SU-8 glue on the silicon wafer with a thickness of 100 μm, Pre-bake at 95°C for 20 minutes, cool down naturally, place the mask on the SU-8 plastic plate, expose to ultraviolet light for 30s, bake at 95°C for 20 minutes, and cool down naturally; use ethyl lactate to develop the above SU-8 glue for 10 minutes, harden at 180°C Membrane for 2 hours, and cool down naturally for later use.

[0054] The preparation of the SU-8 template for the lower structure of the chip: First, cast a layer of SU-8 glue on the silicon wafer, with a thickness of 150 μm, pre-bake at 95°C for 30 minutes, cool down naturally, and place the mask on the SU-8 glue plate. UV exposure for 45s, post-bake at 95°C for 30min...

Embodiment 2

[0056] Preparation of PDMS chip for single cell isolation

[0057]Mix PDMS and initiator uniformly at a volume ratio of 10:1, cast on the two SU-8 templates prepared earlier, cure in an oven at 80°C for 30 minutes, and peel off the PDMS and SU-8 templates to obtain the upper chip and the lower layer with structures Chip; cut the upper PDMS chip into a transparent square pit along the edge of the reservoir, and punch holes at the inlet of the dispersed phase and the inlet of the continuous phase with a puncher; the upper and lower layers of the chip with the structure side are treated with plasma for 120s, bonded Sealed for spare.

Embodiment 3

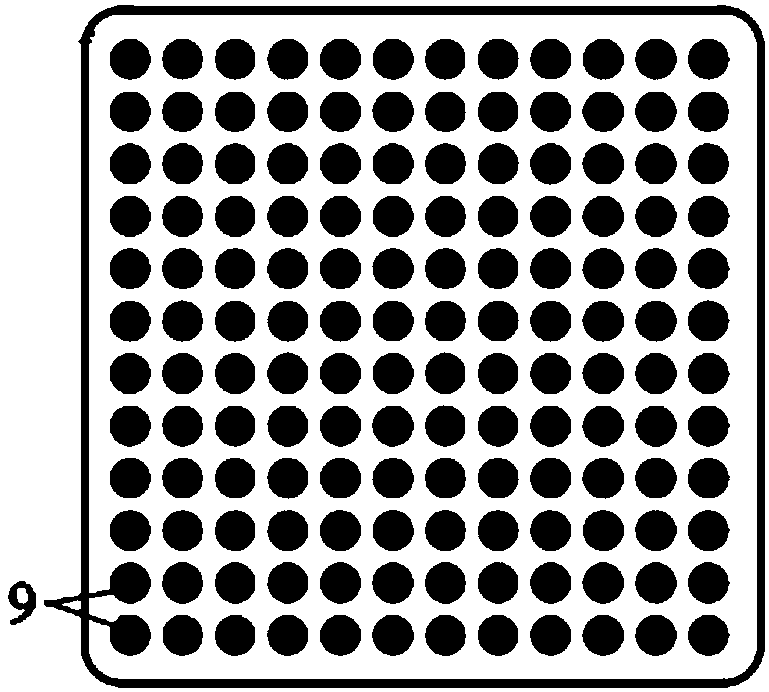

[0059] The density of single cell suspension is 10 4 cells / mL, the chip automatically captures single-cell experiments

[0060] The microfluidic chip prepared above was soaked in 75% ethanol and sterilized by ultraviolet irradiation for 1 h. Subsequently, the single-cell suspension of human glioma cells (U87) was mixed with 10 4 The cell density of cells / mL flows from the dispersed phase inlet 1 through the dispersed phase liquid inlet channel 3 at a flow rate of 1 μL / min; the mineral oil containing 3% (w / w) span80 flows from the continuous phase inlet 2 through the continuous phase liquid inlet Channel 4, the flow rate is 3.5 μL / min, the two-phase liquid converges at the intersection of cross channel 5, the single cell suspension is cut into water-in-oil droplets by mineral oil; single cells are trapped in the droplets, and the droplets pass through the liquid outflow channel 6. Flow into the liquid storage tank 8 from the liquid outlet 7; with the generation of a large numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com