Anticoagulant hydrogel coating capable of catalyzing release of nitric oxide and preparation method of anticoagulant hydrogel coating capable of catalyzing release of nitric oxide

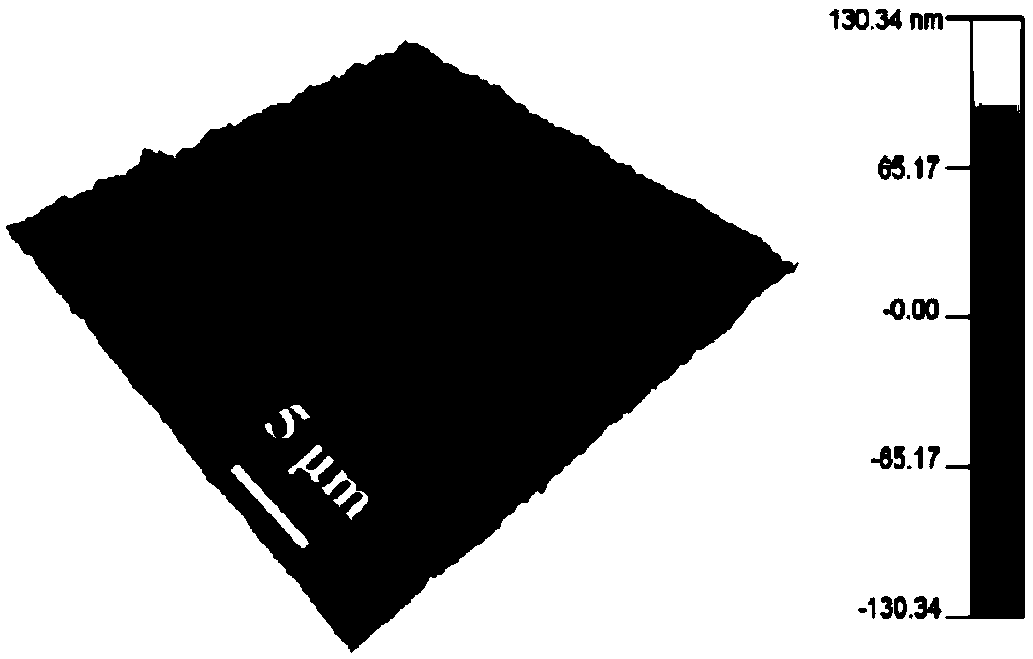

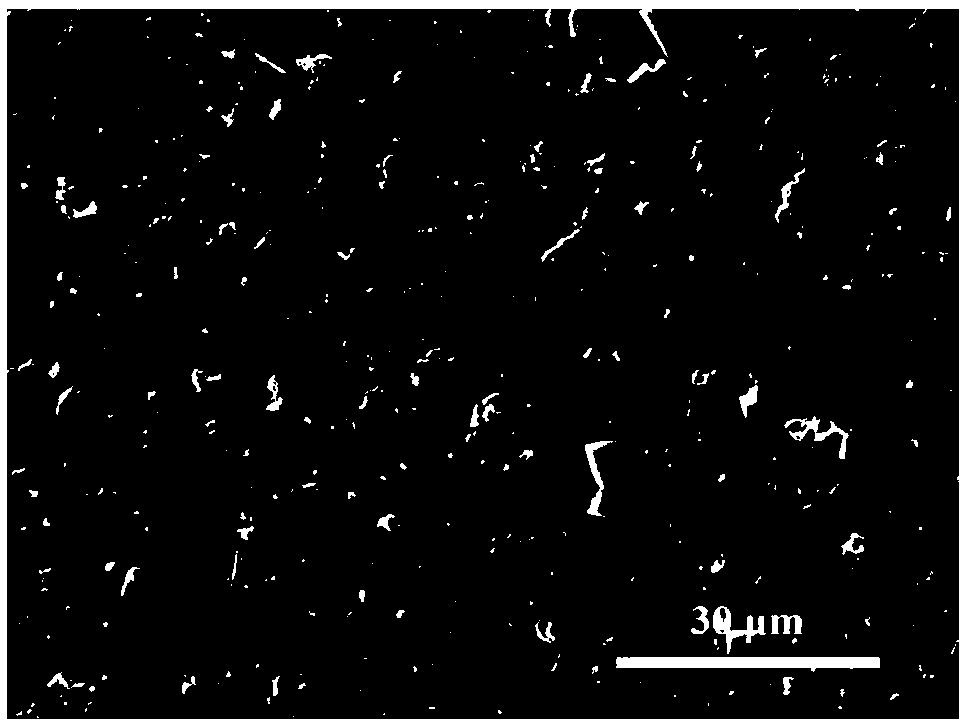

A technology of nitric oxide and blood water, applied in the field of medical materials, can solve the problems of inability to meet the anti-coagulation function, uncontrollable release of nitric oxide, etc., and achieve the effects of excellent stability, good anti-oxidation and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an anticoagulant hydrogel coating that can catalyze the release of nitric oxide, comprising the following steps:

[0030] (1) Ultrasonic cleaning and drying of the stainless steel base material;

[0031] (2) Place the cleaned stainless steel in 0.1mM chitosan solution with a pH value of 6, react at room temperature for 2min, then take it out and wash it with deionized water for 3 times;

[0032] (3) The product obtained in step (2) was placed in a mixed solution with a pH value of 11, containing 1 mM tannic acid and 0.01 mM ebselenium, reacted at room temperature for 5 min, then took it out and washed it with deionized water for 3 times;

[0033] (4) Put the product obtained in step (3) in a 0.1 mM hyaluronic acid solution with a pH value of 11, react at room temperature for 1 min, then take it out and wash it with deionized water for 3 times;

[0034] (5) At room temperature, using the product obtained in step (4) as a substrate, repeat the oper...

Embodiment 2

[0036] A method for preparing an anticoagulant hydrogel coating that can catalyze the release of nitric oxide, comprising the following steps:

[0037] (1) cleaning and drying the titanium alloy base material;

[0038] (2) Place the cleaned titanium alloy in 0.01mM poly-L-arginine hydrochloride solution with a pH value of 7.4, react at room temperature for 2min, then take it out and wash it with deionized water for 3 times;

[0039] (3) Place the product obtained in step (2) at a pH of 7.2 in a mixed solution containing 0.1mM epigallocatechin gallate and 0.01mM cystamine, react at room temperature for 5min, then take it out and rinse with deionized water Wash 3 times;

[0040] (4) Put the product obtained in step (3) in a 0.1 mM polyglutamic acid solution with a pH value of 6.8, react at room temperature for 3 minutes, then take it out and wash it 3 times with deionized water;

[0041] (5) At room temperature, using the product obtained in step (4) as a substrate, repeat the...

Embodiment 3

[0043] A method for preparing an anticoagulant hydrogel coating that can catalyze the release of nitric oxide, comprising the following steps:

[0044] (1) cleaning and drying the polytetrafluoroethylene material;

[0045] (2) Place the cleaned polytetrafluoroethylene in 2mM poly-L-lysine hydrobromide solution with a pH value of 7.4, react at room temperature for 2min, then take it out and wash it with deionized water for 3 times;

[0046] (3) Place the product obtained in step (2) at a pH of 6.5 in a mixed solution containing 0.5mM epigallocatechin and 0.001mM selenocystine, react at room temperature for 2min, then take it out and rinse with deionized water Wash 3 times;

[0047] (4) Put the product obtained in step (3) in a 0.05 mM dextran solution with a pH value of 6.9, react at room temperature for 3 minutes, then take it out and wash it with deionized water for 3 times;

[0048] (5) At room temperature, using the product obtained in step (4) as a substrate, repeat the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com