A kind of anticoagulant hemodialysis membrane and preparation method thereof

A technology of hemodialysis and anticoagulation, applied in the direction of semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of reduced dialysis efficiency and affecting the life safety of dialysis patients, so as to improve the effect of hemodialysis and equipment dependence The effect of low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

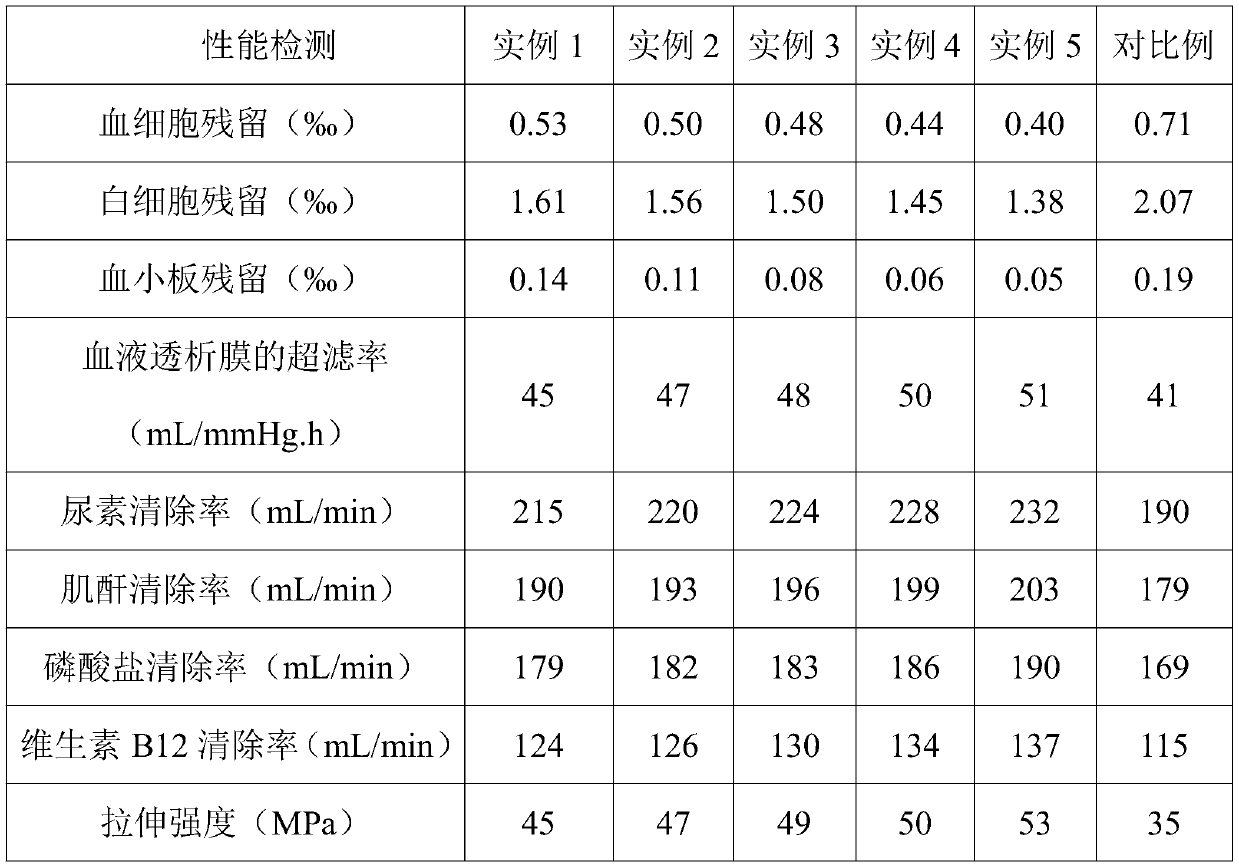

Examples

Embodiment 1

[0030] A preparation method of an anticoagulant hemodialysis membrane, comprising the steps of:

[0031] Ⅰ Preparation of polysulfone amide polycondensate: 32.5 g of bis[4-(4-aminophenoxy)phenyl] sulfone and 10 g of aspartic acid were dissolved in 100 g of dimethyl sulfoxide to form a solution, and the solution was prepared under normal pressure at 150 ℃ for 2.5 hours, then add 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride 8g, 4-dimethylaminopyridine 4g, 1-butyl-3-methanol to the solution 2 g of imidazole trifluoroacetate, heat up to 190°C, conduct the primary polycondensation reaction for 3 hours, then transfer the reaction liquid into the reaction kettle, vacuumize (500Pa), heat to 230°C, and conduct the polycondensation reaction for 8 hours, then place in water Settled out, and then placed in a vacuum drying oven at 98 ° C for 15 hours to obtain a polysulfone amide polycondensate;

[0032] II Dimethyl (3-chloro-2-oxopropyl) phosphonate exchange: Dimethyl (3-chl...

Embodiment 2

[0038]A preparation method of an anticoagulant hemodialysis membrane, comprising the steps of:

[0039] Ⅰ Preparation of polysulfone amide polycondensate: Dissolve 32.5g of bis[4-(4-aminophenoxy)phenyl]sulfone and 10g of aspartic acid in 115g of N,N-dimethylformamide to form a solution , reacted at 155°C under normal pressure for 2.8 hours, then added 8 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 4 g of 4-dimethylaminopyridine, tetrabutyl Ammonium bromide 2g, warming up to 195°C, primary polycondensation reaction for 3.5 hours, then the reaction solution is transferred to the reactor, vacuumed (500Pa), heated to 235°C, polycondensation reaction for 8.5 hours, and then precipitated in water, and then Place it in a vacuum drying oven at 98°C for 15 hours to obtain a polysulfone amide polycondensate;

[0040] II Dimethyl (3-chloro-2-oxopropyl) phosphonate exchange: Dimethyl (3-chloro-2-oxopropyl) phosphonate 23g, hydroxyethyl methylcellulose 7g Join in the ...

Embodiment 3

[0046] A preparation method of an anticoagulant hemodialysis membrane, comprising the steps of:

[0047] Ⅰ Preparation of polysulfone amide polycondensate: Dissolve 32.5 g of bis[4-(4-aminophenoxy)phenyl] sulfone and 10 g of aspartic acid in 125 g of N-methylpyrrolidone to form a solution. React at 160°C for 2.9 hours, then add 8 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 4 g of 4-dimethylaminopyridine, 1,2-dimethyl - 2g of 3-hydroxyethylimidazole hexafluorophosphate, heat up to 200°C, conduct primary polycondensation reaction for 4 hours, then transfer the reaction solution into the reactor, vacuumize (500Pa), heat to 240°C, and conduct polycondensation reaction for 9 hours , and then precipitated in water, and then placed in a vacuum drying oven at 98 ° C for 15 hours to obtain a polysulfone amide polycondensate;

[0048] II Dimethyl (3-chloro-2-oxopropyl) phosphonate exchange: Dimethyl (3-chloro-2-oxopropyl) phosphonate 25g, hydroxyethyl methylcellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com