Preparation method for dysprosium oxide powder

A technology of dysprosium oxide and powder, which is applied in the field of rare earth powder material preparation, can solve the problems of high environmental protection pressure, high production cost, uneven powder dispersion, etc., and achieve the effect of narrow particle size distribution, low environmental protection pressure and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

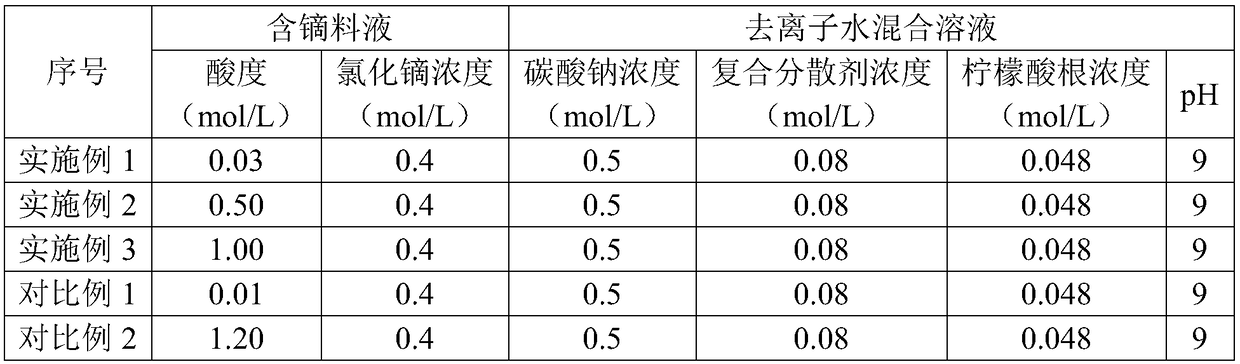

[0037] 1) Prepare dysprosium-containing material liquid, the acidity and dysprosium chloride concentration of the dysprosium-containing material liquid are shown in Table 1;

[0038] 2) Take sodium carbonate and composite dispersant to form a mixed solution of deionized water. The composite dispersant is composed of citric acid and polyacrylic acid. The concentrations of sodium carbonate, composite dispersant and citrate in the mixed solution of deionized water are as shown in Table 1. Show

[0039] 3) While stirring the deionized water mixed solution, drip the dysprosium-containing material liquid at a rate of 30ml / min per liter of the deionized water mixed solution until the amount of dysprosium chloride in the dysprosium-containing material liquid is equal to that of the sodium carbonate material. The volume ratio is 1:1, the reaction temperature is controlled to 40°C, and the reaction solution is filtered to obtain a white precipitate; at this time, the pH of the reaction solut...

Embodiment 2

[0044] 1) Prepare dysprosium-containing material liquid, the acidity and dysprosium nitrate concentration of the dysprosium-containing material liquid are shown in Table 2;

[0045] 2) Take ammonium carbonate and a composite dispersant to form a mixed solution of deionized water. The composite dispersant is composed of ammonium citrate and polyvinyl alcohol with a purity of 95%. In the mixed solution of deionized water, ammonium carbonate, composite dispersant and lemon The acid radical concentration is shown in Table 2;

[0046] 3) While stirring the deionized water mixed solution, drip the dysprosium-containing material solution at a rate of 40ml / min per liter of the deionized water mixed solution to the amount of dysprosium nitrate and ammonium carbonate in the dysprosium-containing material solution The ratio is 1:2.0, the reaction temperature is controlled at 45°C, and the reaction solution is filtered to obtain a white precipitate; at this time, the pH of the reaction solutio...

Embodiment 3

[0051] 1) Prepare dysprosium-containing material liquid, the acidity and dysprosium chloride concentration of the dysprosium-containing material liquid are shown in Table 3;

[0052] 2) Take ammonium bicarbonate and a composite dispersant to form a deionized water mixed solution. The composite dispersant is composed of citric acid and polyethylene glycol 2000. In the deionized water mixed solution, ammonium bicarbonate, composite dispersant and citrate The concentration is shown in Table 3;

[0053] 3) While stirring the deionized water mixed solution, drip the dysprosium-containing material liquid at a rate of 50ml / min per liter of the deionized water mixed solution until the amount of dysprosium chloride and ammonium bicarbonate in the dysprosium-containing material liquid The ratio of the amount is 1:1.6, the reaction temperature is controlled to 50°C, and the reaction liquid is filtered to obtain a white precipitate; at this time, the pH of the reaction liquid is acidic;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com