Co-Se compound nanotube@ foam Ni composite array material as well as preparation method and application thereof

A technology of selenium compounds and composite arrays, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of low catalytic activity, improve catalytic performance, increase electron transfer rate, and reduce overheating. The effect of potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

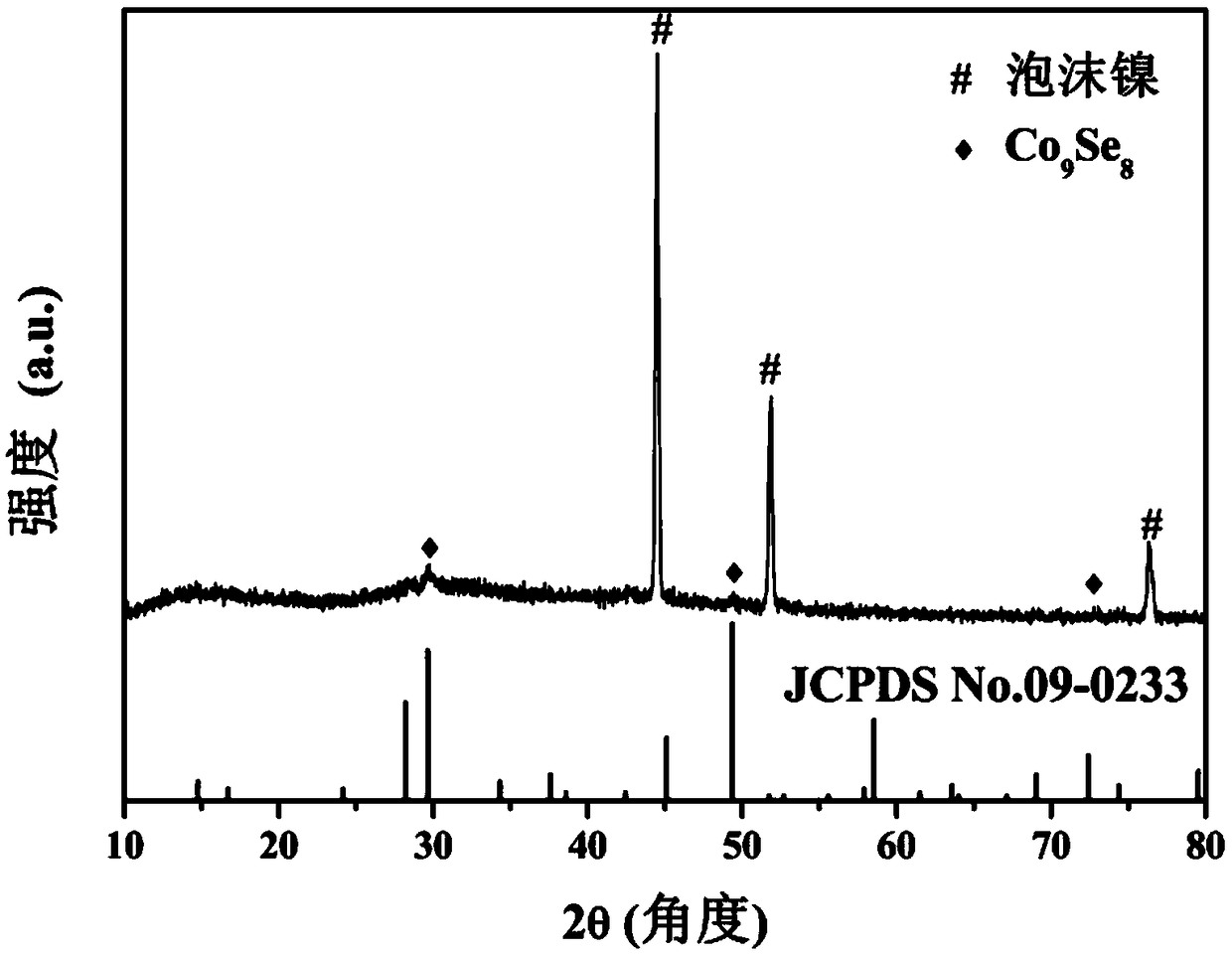

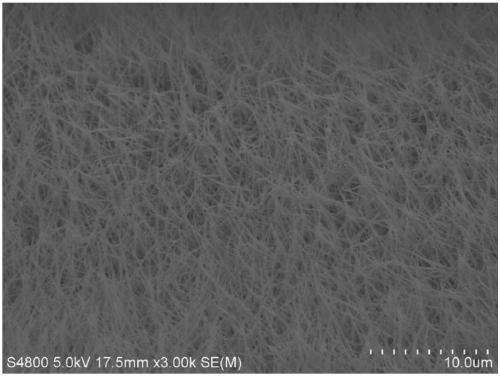

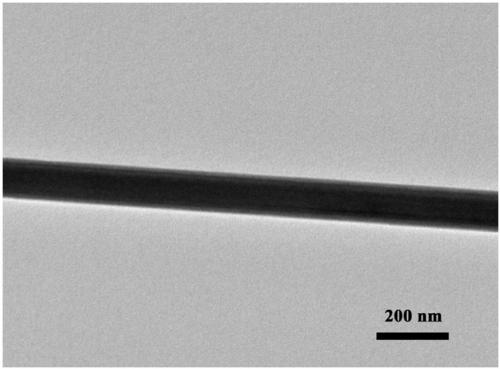

[0039] A kind of Co 9 Se 8 The preparation method of nanotube@foam nickel composite array material comprises the following steps:

[0040] A. Weigh 2mmol cobalt chloride hexahydrate and 12mmol urea, add 30ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, and put it into a 1cm×4cm Nickel foam, after closing the reactor, put it into a constant temperature box, and heat it at 90°C for 10h;

[0041] B. Take out the nickel foam after the reaction in step A, wash it several times with ethanol and deionized water, put it in a vacuum drying oven, and dry it at 65°C for 8 hours to obtain the product of the nickel foam supported cobalt precursor: Co precursor @ foam nickel composite material;

[0042] C. Take 5mmol of selenium powder and add it to 10ml of hydrazine hydrate, stir until dissolved, then add this mixture to 300ml of deionized water, stir and mix evenly; transf...

Embodiment 2

[0050] A kind of Co 9 Se 8 The preparation method of nanotube@foam nickel composite array material comprises the following steps:

[0051] A. Weigh 2.5mmol cobalt chloride hexahydrate and 16mmol urea, add 35ml deionized water and stir until dissolved to obtain a clear and transparent solution; 4cm of nickel foam, after closing the reactor, put it into the incubator, and heat it at 110°C for 8h;

[0052] B. Take out the nickel foam after the reaction in step A, wash it several times with ethanol and deionized water, put it in a vacuum drying oven, and dry it at 65°C for 8 hours to obtain the product of the nickel foam supported cobalt precursor: Co precursor @ foam nickel composite material;

[0053] C. Take 8mmol of selenium powder and add it to 10ml of hydrazine hydrate, stir until dissolved, then add this mixture to 300ml of deionized water, stir and mix evenly; transfer the resulting solution to a polytetrafluoroethylene-lined reactor , put the Co precursor@foam nickel ...

Embodiment 3

[0058] A kind of Co 9 Se 8 The preparation method of nanotube@foam nickel composite array material comprises the following steps:

[0059] A. Weigh 3mmol cobalt chloride hexahydrate and 18mmol urea, add 40ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, and put it into a 1cm×4cm Nickel foam, after closing the reactor, put it into the incubator, and heat it at 140°C for 6 hours;

[0060] B. Take out the nickel foam after the reaction in step A, wash it several times with ethanol and deionized water, put it in a vacuum drying oven, and dry it at 65°C for 8 hours to obtain the product of the nickel foam supported cobalt precursor: Co precursor @ foam nickel composite material;

[0061] C. Take 10mmol of selenium powder and add it to 10ml of hydrazine hydrate, stir until dissolved, then add this mixture to 300ml of deionized water, stir and mix evenly; transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com