Epsilon-polylysine fermentation method adopting cell immobilization and off-site and intermittent adsorption

A technology of polylysine and fermentation method, which is applied in the field of bioengineering applications, and can solve the problems of unfavorable improvement of the yield of ε-polylysine, low fermentation yield, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

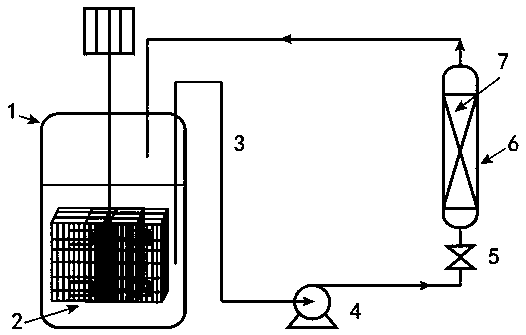

Image

Examples

Embodiment 1

[0020] 1. Spore Suspension Preparation

[0021] The ε-polylysine-producing bacteria was Streptomyces anhydrous ( Streptomyces ahygroscopicus ) GIM8, inoculate the fresh slant strains onto the oat agar medium (preparation method as follows) plate, incubate upside down at 30°C for 7 days, wash with sterile water to collect spores, prepare spore suspension, and make the spore concentration about 5 × 10 8 Spores / mL, as inoculum for preparing liquid seeds;

[0022] Preparation of oat agar medium (taking 1 L as an example): Weigh 40 g of oats, wash with tap water, boil in 1200 mL of deionized water for 10 min, filter and discard the residue, add 18 g of agar to the filtrate, heat to dissolve completely, replenish water To 1 L, sterilize at 121°C for 30 min for plate preparation.

[0023] 2. Liquid Seed Preparation

[0024] Inoculate 10 mL of spore suspension into 500 mL of fermentation medium (packed in a 1 L Erlenmeyer flask) at a temperature of 30 °C and a rotation speed of ...

Embodiment 2

[0036] 1. The preparation of spore suspension, liquid seed, and fermentation medium formula are the same as in Example 1

[0037] 2. Immobilization carrier installation and fixation

[0038] Use the sponge as the cell immobilization carrier (cut into length, width and thickness about 30 cm×10 cm×1.5 cm), and fix it to the stirrer, shaft and baffle plate of a 10 L fermenter with fine iron wire, and the dosage is 8 pieces.

[0039] 3. Sterilization, inoculation and fermentation

[0040] Pour 6.7 L of fermentation medium into the fermenter and sterilize at 121°C for 30 minutes; after cooling, use 12.5% ammonia water to adjust the initial pH of the medium to 6.8; add liquid seeds according to the inoculation amount of 5% (v / v); ferment The conditions were ventilation flow rate 1.0 vvm, temperature 30°C, rpm = 0.

[0041] 4. pH control, nutrient supplement, feeding and defoaming

[0042] During the fermentation process, when the pH of the fermentation liquid dropped to 3.8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com