Skin-core double-layer leather protein fiber and preparing method thereof

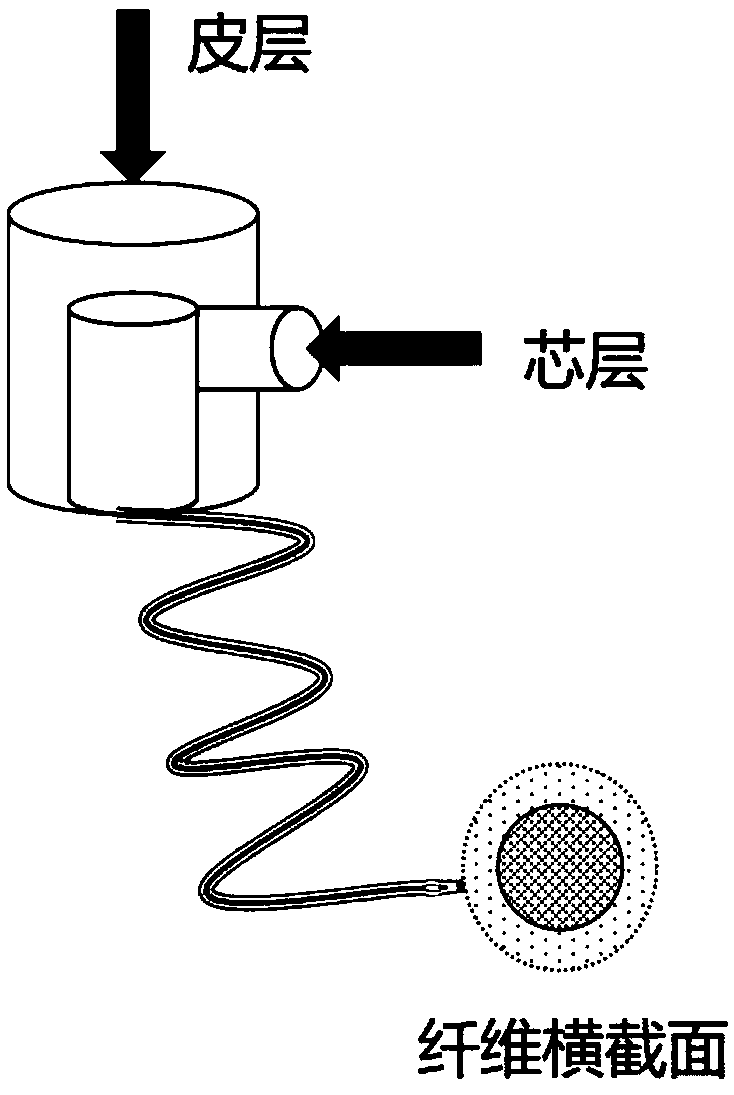

A feather protein and double-layer technology is applied in the field of skin-core double-layer feather protein fiber and its preparation, which can solve the problems of incompatibility of fiber mechanical properties and functionality, loss of protein functionality, poor mechanical properties of feather protein fibers, and the like. To achieve the effect of economic value and environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a skin-core double-layer feather protein fiber, comprising the following steps:

[0035] 1) Preparation of feather protein powder: waste feather down is placed in urea / sodium hydroxide system, urea concentration is 7wt%, sodium hydroxide concentration is 3wt%, the mass ratio of feather down and urea / sodium hydroxide system is 1: 50, stirring and dissolving at room temperature for 12 hours to obtain a feather protein solution, after dialysis treatment, to obtain a pure protein solution, and then to obtain feather protein powder through the processes of concentration, evaporation, drying and grinding; figure 2 In order to prepare the optical micrograph of the process of dissolving feathers in urea / sodium hydroxide system, the magnification is 400 times; from left to right, they are dissolved for 4, 7, and 11 hours;

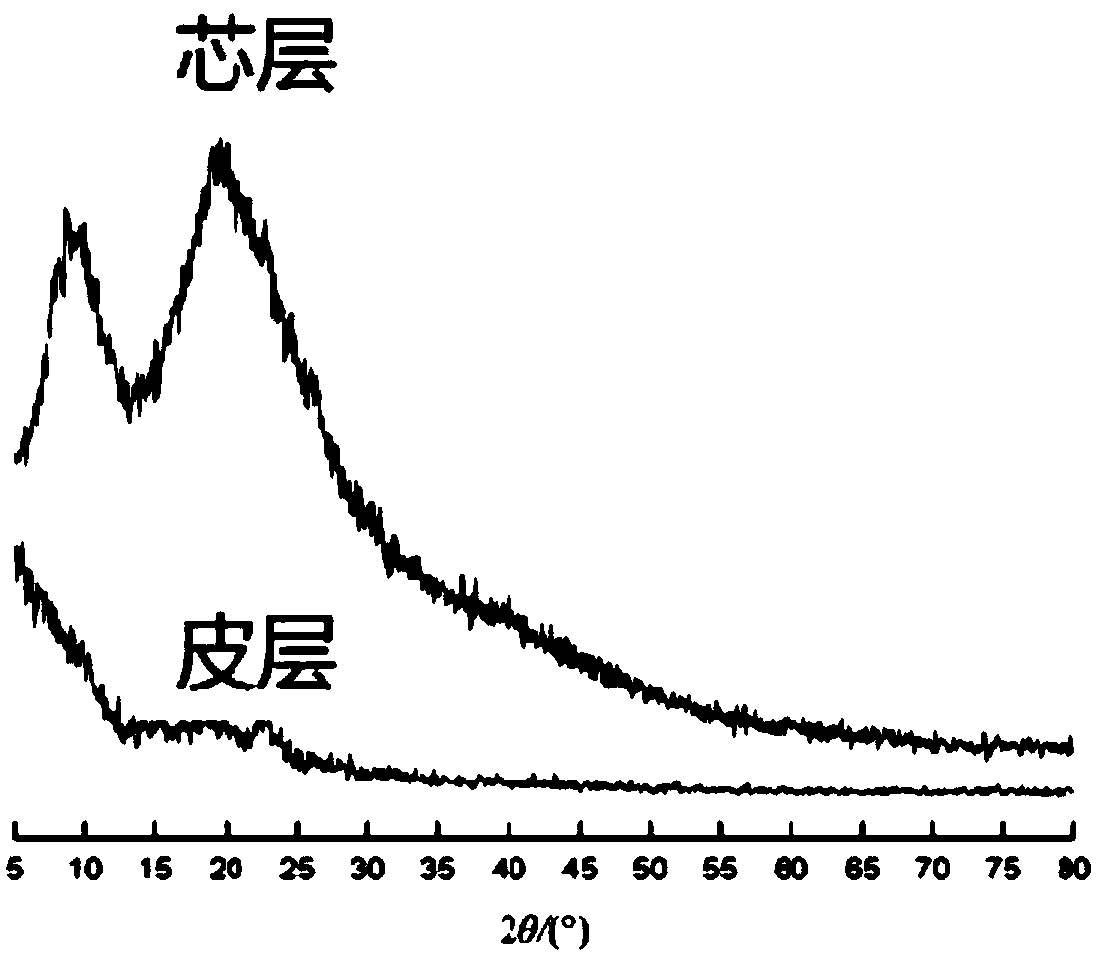

[0036] 2) Preparation of the core layer spinning solution: the feather protein powder, phytic acid and methanol prepared in step 1) w...

Embodiment 2

[0040] A method for preparing a skin-core double-layer feather protein fiber, which prepares a skin-core double-layer feather protein fiber with super-strong thermal insulation, comprising the following steps:

[0041]1) preparation of feather protein powder: with embodiment 1;

[0042] Preparation of the core layer spinning solution: the feather protein powder, phytic acid and methanol prepared in step 1) were successively dissolved in hexafluoroisopropanol solvent, and the mass ratio of feather protein powder, phytic acid and methanol was 100:3:5 , stirred until uniformly dissolved, and prepared into a 16wt% protein solution, then adding nanometer zirconium oxychloride to the protein solution to make its mass percentage in the solution 1.25%, then adding sodium alginate to make its mass concentration be 0.2%, as a dispersion stabilizer, fully stirred until uniformly dispersed, ready for use;

[0043] 3) Preparation of cortex spinning solution: dissolve the feather protein p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com