A germanium channel field effect transistor device with an optical gate and its manufacturing method

A manufacturing method and transistor technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that the parasitic capacitance between the gate and the source and drain is difficult to eliminate, so as to reduce power consumption, eliminate parasitic resistance, The effect of high current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: In this embodiment, a quartz substrate is used, and the preparation method of a germanium channel field effect transistor device with an optical gate is as follows:

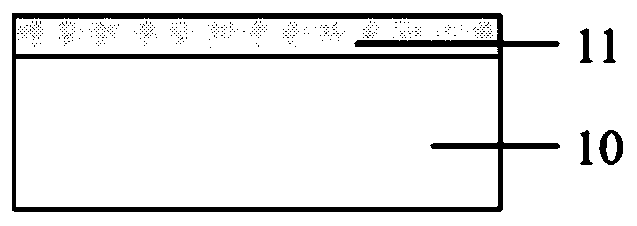

[0052] (1) As shown in FIG. 1(a), a germanium film 11 is deposited on the quartz substrate 10 with a thickness of 3 nanometers to 30 nanometers, and the deposition method is chemical vapor deposition, evaporation or sputtering;

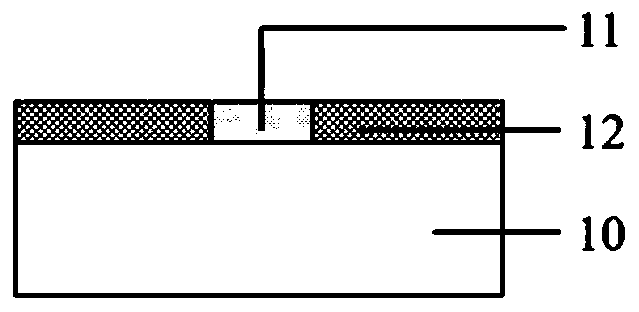

[0053] (2) As shown in FIG. 1(b), the germanium film 11 is doped to form a heavily doped germanium region 12 as the source and drain regions of the device, and the doping method is ion implantation or thermal diffusion;

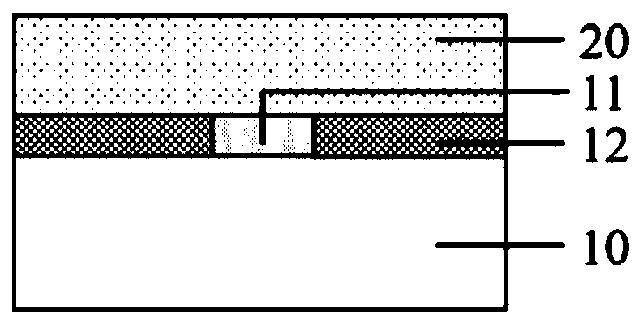

[0054] (3) As shown in FIG. 2( a ), a gate insulating layer 20 is deposited on the surface of the germanium thin film 11 and the heavily doped germanium region 12 . The material of the gate insulating layer 20 includes but is not limited to aluminum oxide and silicon oxide, and the thickness is 100 nanometers. To 500 nm, the deposition method is che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com