Lithium negative electrode protective film, preparation method and lithium metal secondary battery

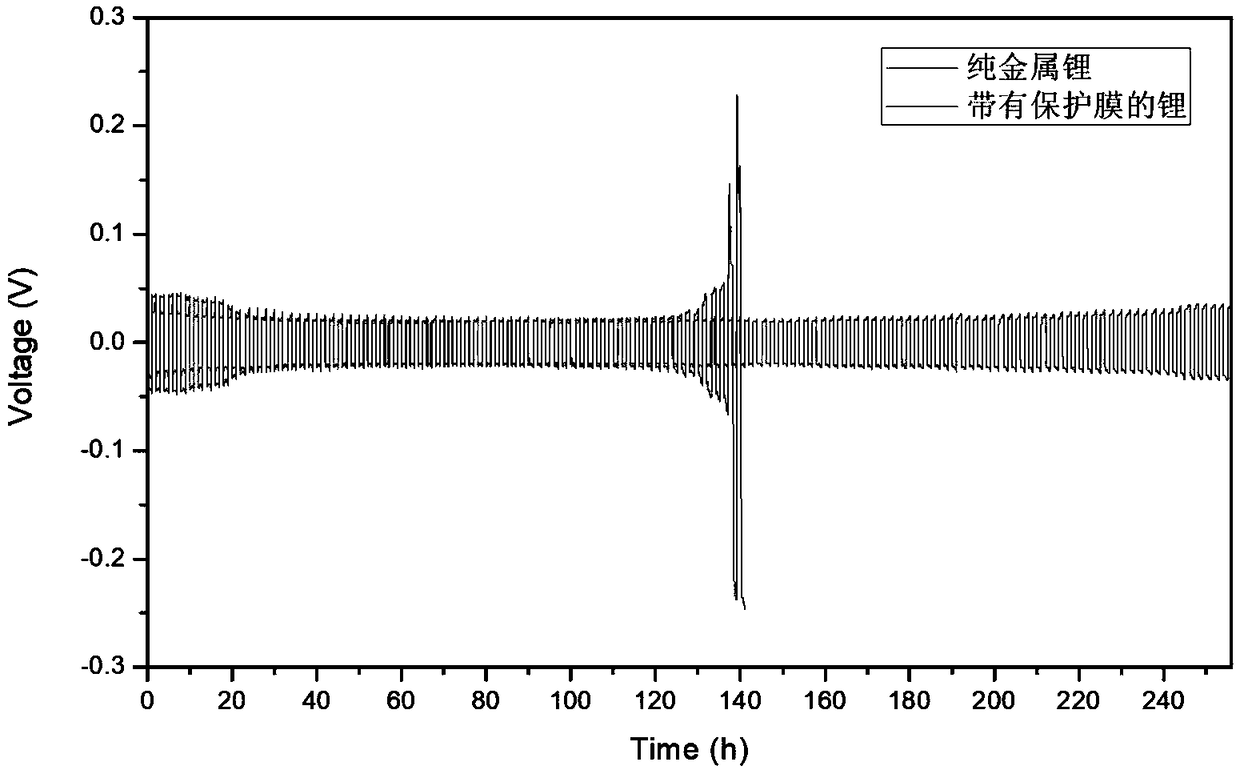

A technology of protective film and lithium negative electrode, which is applied in the direction of secondary battery, secondary battery repair/maintenance, lithium battery, etc. It can solve the problem of poor mechanical properties of modified SEI film, uneven surface morphology of metal lithium, and uneven surface charge distribution and other problems, to achieve the effects of easy mass production, uniform deposition and shedding, and inhibition of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve 1.4354g lithium bistrifluoromethanesulfonimide in 10ml of 1-ethyl-3-methylimidazole bistrifluoromethanesulfon in a glove box filled with Ar gas and with a moisture content of 0.1 ppm or less. In the imide salt, mix and dissolve to obtain a mixed solution. The concentration of lithium bistrifluoromethanesulfonimide in 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt is 0.5mol / L ;

[0046] (2) Put 0.5g of the mixed solution prepared in step (1) and 1g of zirconium dioxide with an average particle size of 50nm in a ball milling jar, and put 37.5g of ceramic balls into it, and mix the ball mill with a planetary ball mill at a speed of 300r / min, ball milling time is 30min, mix evenly, and then take it out to obtain quasi-solid electrolyte;

[0047] (3) Weigh 20g of Nafion solution, dissolve 0.1g of lithium hydroxide in 20g of deionized water to obtain a lithium hydroxide solution, add dropwise the lithium hydroxide solution in the Nafion solution for li...

Embodiment 2

[0056] (1) Dissolve 3.7414 lithium bisfluorosulfonimide in 10ml of N-methyl, propylpyrrole bistrifluoromethanesulfonimide in a glove box filled with Ar gas and with a moisture content of less than or equal to 0.1 ppm , Mixed and dissolved to obtain a mixed solution, the concentration of lithium bistrifluoromethanesulfonimide in N-methyl, propylpyrrole bistrifluoromethanesulfonimide salt is 2mol / L;

[0057] (2) Put 0.5g of the mixed solution prepared in step (1) and 1g of silica with an average particle size of 100nm in a ball milling tank, and put 37.5g of ceramic balls into it, and mix the ball with a planetary ball mill at a speed of 300r / min, ball milling time is 30min, mix well, and then take it out to obtain quasi-solid electrolyte;

[0058] (3) Weigh 20g of Nafion solution, dissolve 0.1g of lithium hydroxide in 20g of deionized water to obtain a lithium hydroxide solution, add dropwise the lithium hydroxide solution in the Nafion solution for lithiation treatment until the p...

Embodiment 3

[0067] (1) Dissolve 2.8708g lithium bistrifluoromethanesulfonimide in 10ml N-methyl, propylpyrrole bistrifluoromethanesulfonimide in a glove box filled with Ar gas and moisture content less than or equal to 0.1ppm In the salt, mix and dissolve to obtain a mixed solution, the concentration of lithium bistrifluoromethanesulfonimide in N-methyl, propylpyrrole bistrifluoromethanesulfonimide salt is 1mol / L;

[0068] (2) Put 0.5g of the mixed solution prepared in step (1) and 1g of titanium dioxide with an average particle size of 50nm in a ball milling tank, and put 37.5g of ceramic balls into it, and mix the ball mill with a planetary ball mill at a speed of 300r / min, the ball milling time is 200min, mix evenly, and then take it out to obtain a quasi-solid electrolyte;

[0069] (3) Weigh 20g of Nafion solution, dissolve 0.1g of lithium hydroxide in 20g of deionized water to obtain a lithium hydroxide solution, dropwise add lithium hydroxide solution in Nafion solution for lithiation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com