Chitosan/kit-6 type silicon-based composite material and its preparation method and application

A silicon-based composite material, KIT-6 technology, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problems of low ion exchange capacity, limited progress, low heavy metal ion adsorption performance, etc. To achieve the effect of shortening synthesis time, simple method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

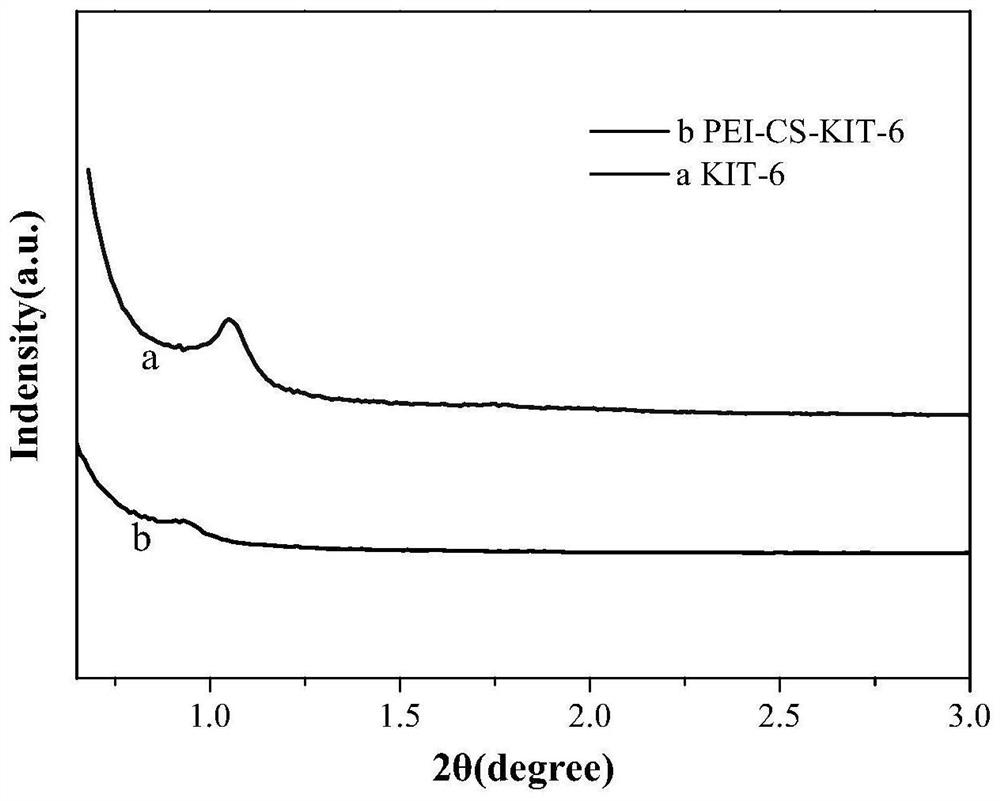

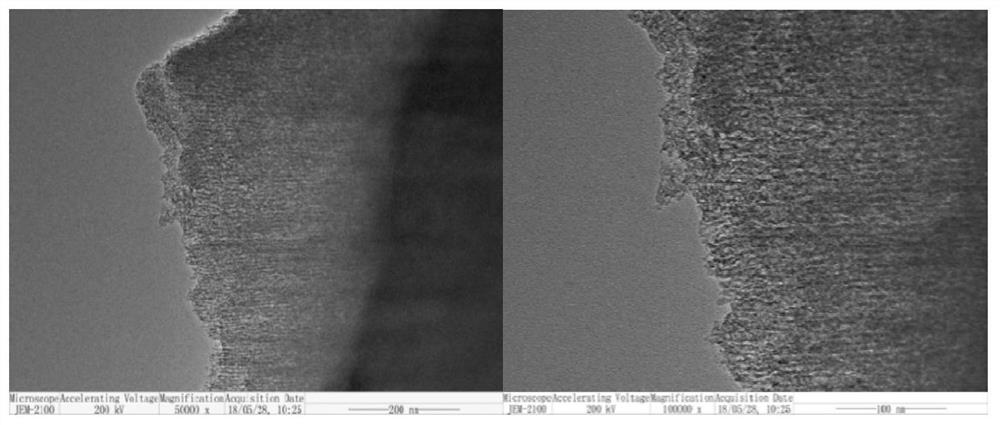

[0032] Embodiment 1 Chitosan / KIT-6 type silicon-based composite material PEI-CS-KIT-6

[0033] The synthetic route of chitosan / KIT-6 silicon-based composite material PEI-CS-KIT-6 is as follows:

[0034]

[0035] (1) Preparation method

[0036] 1) Put 4g of P123 into an Erlenmeyer flask, add 120g of water, add 20mL of concentrated hydrochloric acid, stir in a water bath at 35°C overnight, then add 4g of n-butanol drop by drop, react for 1 hour, then add 8.6g of TEOS, and react 2h, the resulting reaction solution is KIT-6 solution.

[0037] 2) Dissolve 2g CS in 50mL acetic acid, stir and dissolve to obtain a chitosan (CS) solution. Pour the KIT-6 solution obtained in step 1) into the chitosan (CS) solution, then add 15 mL of glutaraldehyde dropwise, continue the reaction at 35° C. for 22 hours, then transfer to an autoclave, and conduct a hydrothermal reaction at 100° C. for 20 hours. Suction filtration, wash with alcohol first, then wash with water until neutral, and dry ...

Embodiment 2

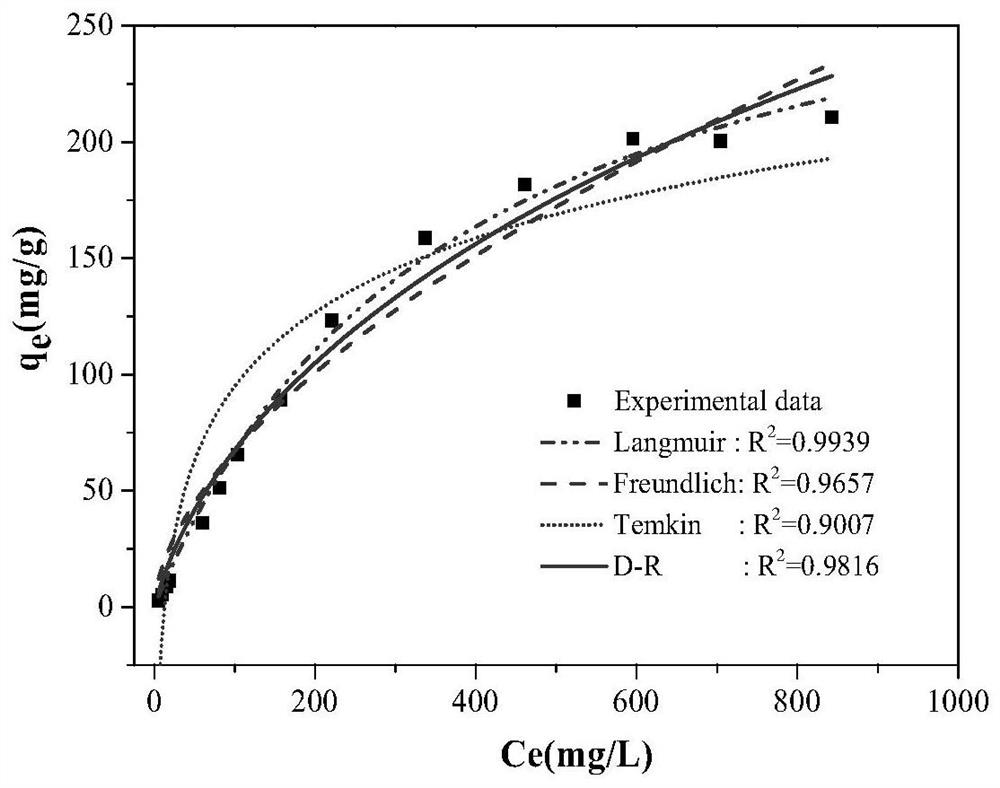

[0044] Embodiment 2 chitosan / KIT-6 type silicon-based composite material PEI-CS-KIT-6 is to the adsorption of Cr (VI)

[0045] Method: take the solution containing hexavalent chromium, adjust the pH to 1-8, add the chitosan / KIT-6 type silicon-based composite material PEI-CS-KIT prepared in Example 1 according to the ratio of solid-liquid ratio 1mg:1ml -6, adsorption at 303K for 24 hours by shaking.

[0046] (1) Adsorption effect on Cr(VI) under different acidity

[0047] Method: Take the hexavalent chromium solution with a pH of 1, 2, 4, 6, and 8 and a concentration of 20ppm respectively, add the PEI-CS-KIT-6 prepared in Example 1 at a solid-to-liquid ratio of 1mg:1ml, and add it at 303K Shock adsorption for 24h. The adsorption rate was measured, and the results were as follows Figure 5 As shown, at pH 1-4, -NH 2 is protonated, while Cr(VI) is mainly HCrO 4 - with Cr 2 o 7 2- The existence of the form makes Cr(VI) easy to be adsorbed, and the adsorption rate can reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com