Nano polyester film for adsorbing heavy metals and preparation method thereof

A technology for adsorbing heavy metals and polyester films, applied in alkali metal compounds, chemical instruments and methods, adsorption of water/sewage treatment, etc., to achieve good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

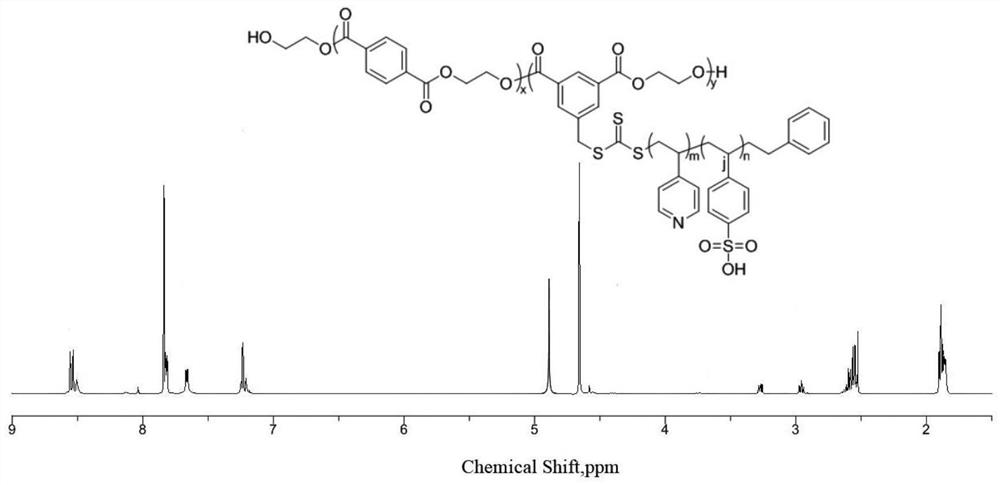

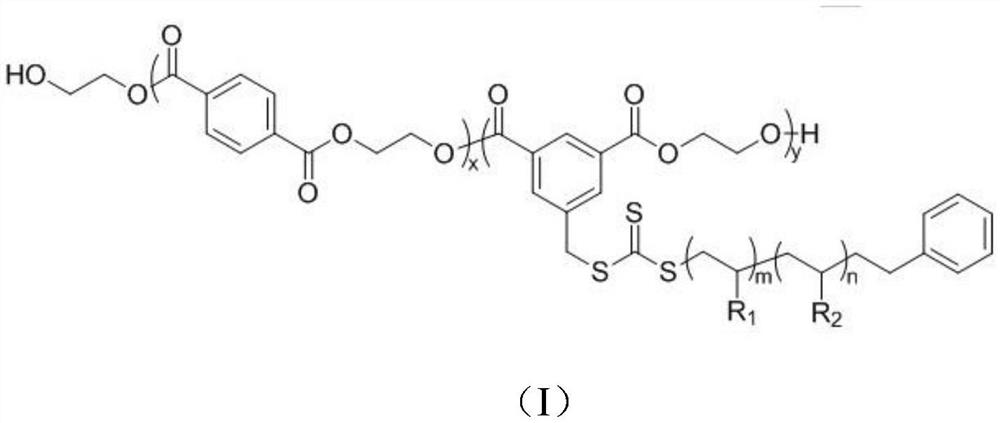

[0041] Preparation of DMIP-S

[0042] Prepare 500 mL of KOH aqueous solution with pH = 8.5, add 50.05 g (0.36 mol) of benzene ethyl mercaptan, stir evenly, add 27.57 g (0.36 mol) of carbon disulfide dropwise, stir at room temperature for 5 hours, raise the temperature to 85 ° C, and add 103.96g (0.362mol) dimethyl 5-bromomethylisophthalate was stirred for 8h. The reaction solution was distilled under reduced pressure to remove the solvent, and the eluent was passed through the column with dichloromethane to obtain an orange-yellow product with a yield of 76.21%.

Embodiment 2

[0044] Prepare copolyester, denoted as A1.

[0045] Weigh 27.79g (0.14mol) of dimethyl terephthalate, 10.03g (0.024mol) of DMIP-S, 17.74g (0.19mol) of ethylene glycol, 0.08g of trimethyl phosphate, and 0.08g of antimony acetate into the reactor , pass into N 2 , carry out transesterification reaction at 200°C for 4h; then raise the temperature to 240°C, start the vacuum pump to control the vacuum degree within 0.2MPa and carry out precondensation for 4h; continue to raise the temperature to 260°C, control the vacuum degree below 50Pa, and start the total polycondensation After reacting for 5 hours, the vacuum was released with nitrogen and the material was discharged. After cooling, it was sliced to obtain a copolyester with an intrinsic viscosity of 0.69 dL / g.

Embodiment 3

[0047] Prepare copolyester, denoted as A2.

[0048] Weigh 31.74g (0.16mol) of dimethyl terephthalate, 6.25g (0.015mol) of DMIP-S, 17.97g (0.19mol) of ethylene glycol, 0.06g of trimethyl phosphate, and 0.09g of antimony acetate into the reactor , pass into N 2, carry out the transesterification reaction at 180°C for 5 hours; then raise the temperature to 220°C, start the vacuum pump to control the vacuum degree within 0.4MPa and carry out precondensation for 4 hours; continue to raise the temperature to 240°C, control the vacuum degree below 50Pa, and start the total polycondensation After reacting for 5 hours, the vacuum was released with nitrogen and the material was discharged. After cooling, it was sliced to obtain a copolyester with an intrinsic viscosity of 0.76 dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com