Remediation method for arsenic contaminated soil

A remediation method, arsenic-polluted technology, applied in the field of remediation of arsenic-contaminated soil, can solve problems such as immature stabilization methods, and achieve the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

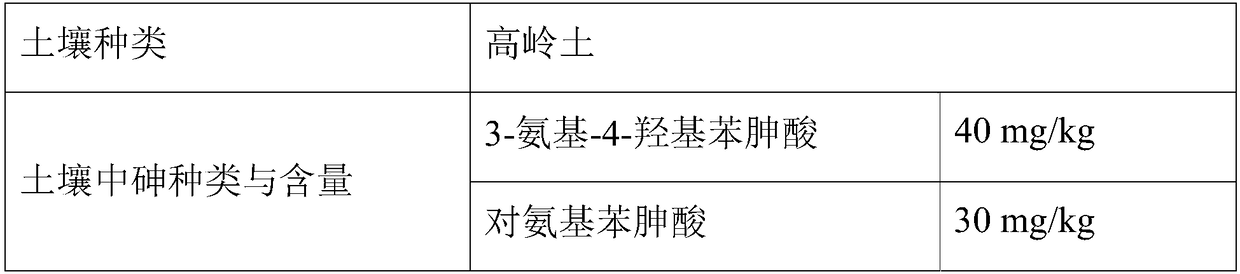

[0028] The test soil preparation is as follows Table 1

[0029] Table 1

[0030]

[0031] experiment procedure:

[0032] (1) Stir the soil and water at a ratio of 1:200 to make a slurry, then add 1mol / L of a mixture of sodium polyphosphate and sodium silicate, and stir evenly;

[0033] (2) Iron alloy material is used as anode, aluminum alloy material is used as cathode, and the constant current density is 50mA / cm 2 . Expose air at a speed of 50ml / s to the uniformly stirred mud in step (1), and continuously stir the electrolysis reaction for 2h;

[0034] (3) Switch electrodes and adjust the constant current density to 150mA / cm 2 , stop the aeration, and continue stirring the electrolysis reaction of the mud obtained in step (2) for 1 hour.

[0035] After the electrolysis was completed and the mud was stabilized for 48 hours, it was detected that the removal rates of 3-amino-4-hydroxyphenylarsineic acid and p-aminophenylarsineic acid in the soil reached 90% and 95% respe...

Embodiment 2

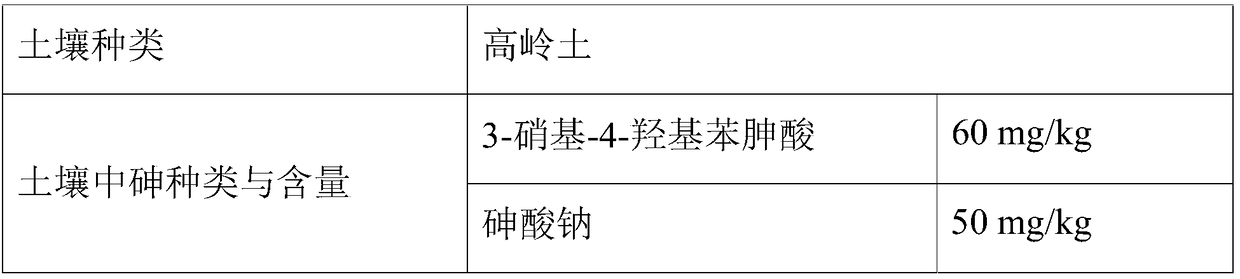

[0037] The test soil preparation is as follows Table 2

[0038] Table 2

[0039]

[0040] experiment procedure:

[0041] (1) Stir the soil and water at a ratio of 1:180 to make a slurry, then add 4mol / L of ethylenediaminetetraacetic acid and sodium silicate mixture, and stir evenly;

[0042] (2) Using scrap iron material as the anode, aluminum material as the cathode, and a constant current density of 80mA / cm 2 . Expose air at a speed of 50ml / s into the uniformly stirred mud in step (1), and continue to stir the electrolysis reaction for 2.5h;

[0043] (3) Switch electrodes and adjust the constant current density to 200mA / cm 2 , stop the aeration, and continue stirring the electrolysis reaction of the mud obtained in step (2) for 1.5h.

[0044] After the electrolysis was completed and the mud was stabilized for 48 hours, it was detected that the removal rate of 3-nitro-4-hydroxyphenylarsine acid in the soil was 90%, and the removal rate of sodium arsenate was 98%, whic...

Embodiment 3

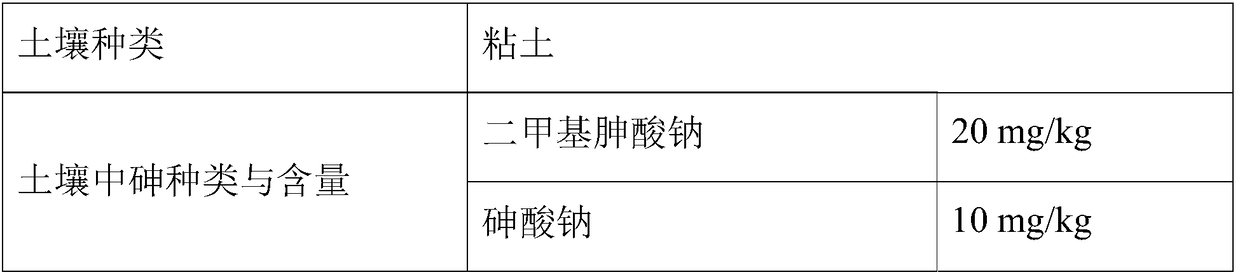

[0046] The test soil preparation is as follows Table 3

[0047] table 3

[0048]

[0049] experiment procedure:

[0050] (1) Stir the soil and water at a ratio of 1:190 to make a slurry, then add 2mol / L mixture of ethylenediaminetetraacetic acid and sodium silicate, and stir evenly;

[0051] (2) Using pure iron as the anode and pure aluminum as the cathode, the constant current density is 25mA / cm 2 . Expose air at a speed of 100ml / s into the uniformly stirred mud in step (1), and continue to stir the electrolysis reaction for 1h;

[0052] (3) Switch electrodes and adjust the constant current density to 100mA / cm 2 , stop the aeration, and continue stirring the electrolysis reaction of the mud obtained in step (2) for 0.5h.

[0053] After the electrolysis was completed and the mud was stabilized for 48 hours, it was detected that the removal rate of sodium dimethylarsinate in the soil was 95%, and the removal rate of sodium arsenate was 99%. The As in the repaired soil w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com