A method for making microfluidic chip molds by using numerical control engraving technology combined with paraffin substrates

A technology of microfluidic chip and numerical control engraving machine, applied in the field of micromachining, can solve the problems of restricting the development and practical application of microfluidic technology, harsh processing environment, complex processing process, etc., to accelerate research and practical application, and easy to operate. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

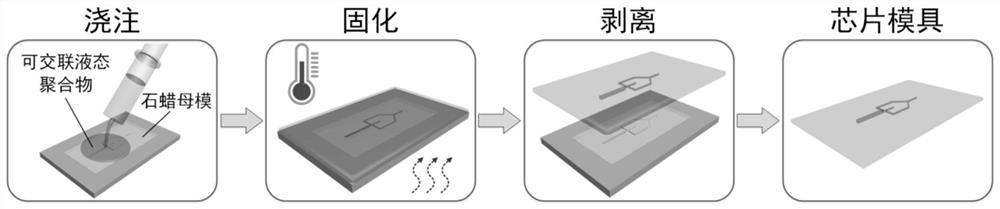

[0053] To make a focused droplet microfluidic chip mold based on epoxy glue, the specific steps are:

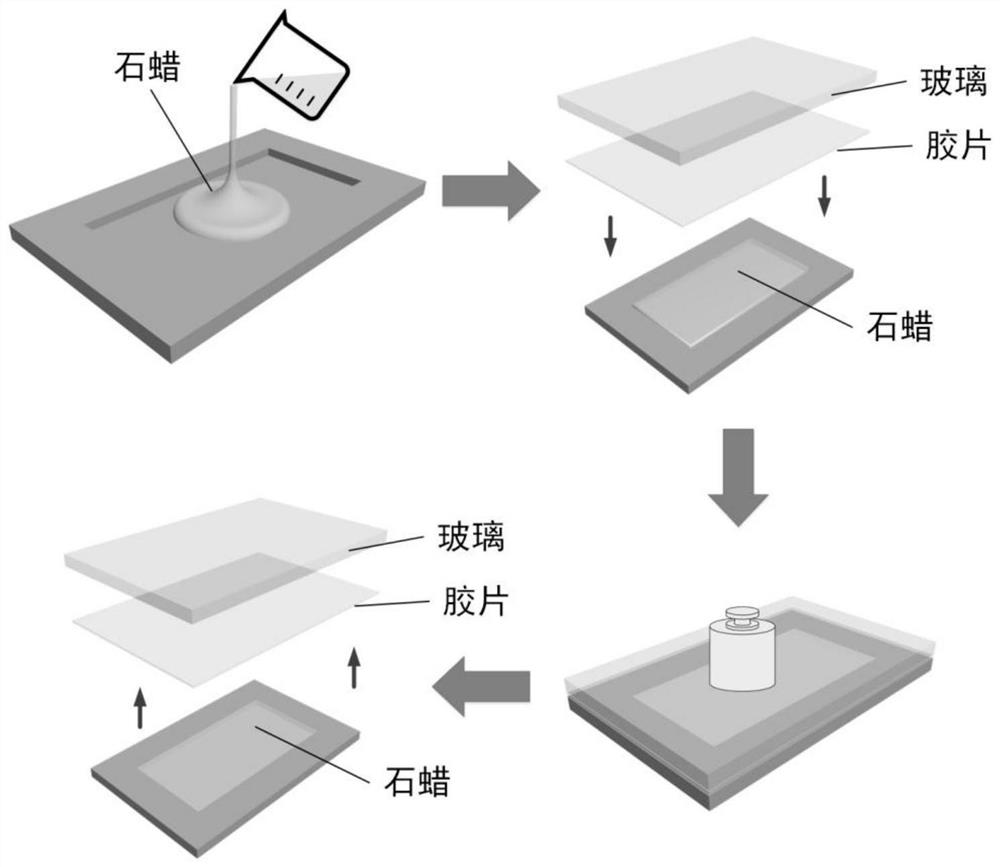

[0054](1) Production of paraffin substrate: A hollowed glass plate and another flat glass plate are bonded with double-sided tape to form a flat plate with a cavity; the plate is placed on a 100°C hot plate, and the cavity Inject melted microcrystalline wax into the cavity so that the paraffin liquid level is slightly higher than the upper surface of the cavity; then press a piece of film and a flat glass plate on the paraffin liquid; turn off the power supply of the hot plate to cool and solidify the paraffin liquid; wait for the paraffin to cool After reaching room temperature, remove the glass cover and peel off the film to obtain a paraffin substrate with a smooth surface. The preparation process is as follows: figure 2 shown.

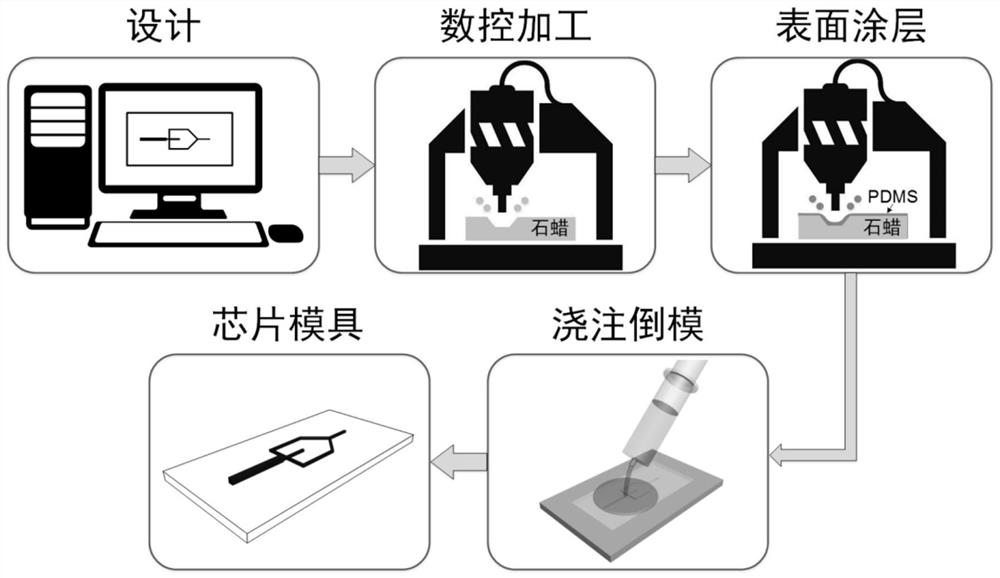

[0055] (2) Paraffin wax master mold engraving: First, use AutoCAD software to draw the pipeline graphics of the focused droplet microfluidic ch...

Embodiment 2

[0059] To make a focused droplet microfluidic chip mold based on ultraviolet glue, the specific steps are:

[0060] (1) Production of paraffin substrate: A hollowed glass plate and another flat glass plate are bonded with double-sided tape to form a flat plate with a cavity; the plate is placed on a 100°C hot plate, and the cavity Inject melted microcrystalline wax into the cavity so that the paraffin liquid level is slightly higher than the upper surface of the cavity; then press a piece of film and a flat glass plate on the paraffin liquid; turn off the power supply of the hot plate to cool and solidify the paraffin liquid; wait for the paraffin to cool After reaching room temperature, remove the glass cover and peel off the film to obtain a paraffin substrate with a smooth surface. The preparation process is as follows: figure 2 shown.

[0061] (2) Paraffin wax master mold engraving: First, use AutoCAD software to draw the pipeline graphics of the focused droplet microflu...

Embodiment 3

[0065] To make a focused droplet microfluidic chip mold based on alumina ceramics, the specific steps are:

[0066] (1) Production of paraffin substrate: A hollowed glass plate and another flat glass plate are bonded with double-sided tape to form a flat plate with a cavity; the plate is placed on a 100°C hot plate, and the cavity Inject melted microcrystalline wax into the cavity so that the paraffin liquid level is slightly higher than the upper surface of the cavity; then press a piece of film and a flat glass plate on the paraffin liquid; turn off the power supply of the hot plate to cool and solidify the paraffin liquid; wait for the paraffin to cool After reaching room temperature, the glass cover plate was removed, and the film was peeled off to obtain a paraffin substrate with a smooth surface.

[0067] (2) Paraffin wax master mold engraving: First, use AutoCAD software to draw the pipeline graphics of the focused droplet microfluidic chip. The width and depth of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com