Molybdenum carbide material and molybdenum carbide@molybdenum sulfide composite material, and preparation methods and applications thereof

A composite material, molybdenum carbide technology, applied in the direction of molybdenum sulfide, carbide, tungsten/molybdenum carbide, etc., can solve the problems of easy stacking of two-dimensional layered structure, low catalytic activity, limited active sites, etc., to achieve improvement Structure and performance improvement and application, the effect of high catalytic activity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a kind of preparation method of molybdenum carbide material, wherein, comprise:

[0037] Step A: Add carbon source and molybdenum source to the dispersion, stir for 6-12 h (preferably 8 h), then dry at 80-120 °C for 12-24 h, grind for 20-30 min, collect, and form carbonization Molybdenum precursor;

[0038] Step B. Place the above-mentioned molybdenum carbide precursor in a clean magnetic boat, place the magnetic boat in a tube furnace, and raise the temperature of the molybdenum carbide precursor from room temperature to 400-900 °C under an inert atmosphere , calcined at this temperature for 1-3 h, ground and collected to obtain molybdenum carbide material.

[0039] Specifically, in step A, the carbon source is selected from one or more of dicyandiamine, melamine, cyanuric acid, benzomelamine, urea, glucose and sucrose. The above-mentioned carbon source of the present invention is relatively common and easy to obtain, which is conducive...

Embodiment 1

[0053] Example 1 Preparation, characterization and electrocatalytic performance test of molybdenum carbide material

[0054] (1) Weigh 1.26 g of melamine, 1.29 g of cyanuric acid, and 0.618 g of ammonium heptamolybdate into a beaker, add 60 mL of deionized water, stir for 8 h to form a uniform dispersion, and put it in a drum at 80 °C Dry in an air oven, then grind for 30 min and collect to obtain the molybdenum carbide precursor.

[0055] (2) Place the above-mentioned molybdenum carbide precursor in a clean magnetic boat, and place the magnetic boat in a tube furnace. Under a nitrogen atmosphere, the temperature of the tube furnace is programmed from room temperature to 750 °C at a rate of 5 °C / min. ℃, and calcined at 750 ℃ for 2 h, then the tube furnace was naturally cooled to 100 ℃, the samples were taken out, ground and collected to obtain molybdenum carbide materials.

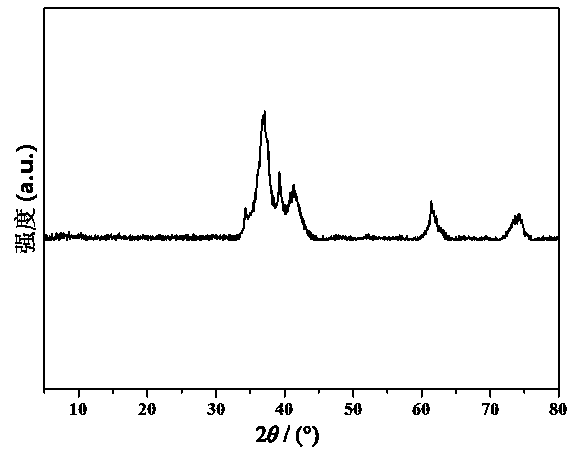

[0056] The molybdenum carbide material was tested by X-ray powder diffraction (XRD for short), and t...

Embodiment 2

[0058] Preparation, characterization and electrocatalytic performance test of embodiment 2 molybdenum carbide material

[0059] (1) Weigh 1.29 g of melamine, 1.29 g of cyanuric acid, and 0.618 g of ammonium heptamolybdate into a beaker, add 60 mL of deionized water, stir for 8 h to form a uniform dispersion, and put it in a drum at 80 °C Dry in an air oven, then grind for 30 min and collect to obtain the molybdenum carbide precursor.

[0060] (2) Place the above molybdenum carbide precursor in a clean magnetic boat, and place the magnetic boat in a tube furnace. Under an argon atmosphere, the tube furnace is programmed to heat up from room temperature to 550 °C, and calcined at 550 °C for 2 h, then the tube furnace was naturally cooled to 100 °C, the samples were taken out, ground and collected to obtain molybdenum carbide materials.

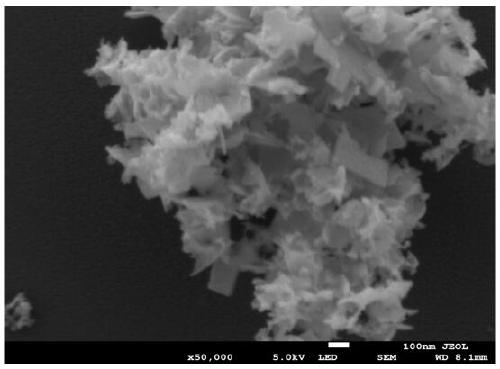

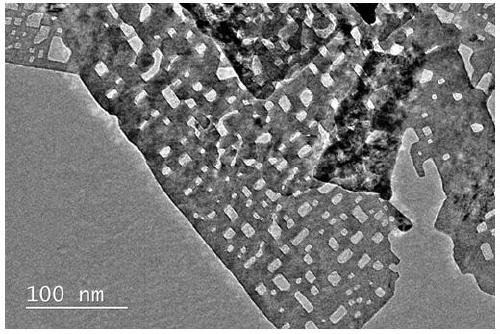

[0061] Carry out X-ray powder diffraction test to this molybdenum carbide material, its XRD pattern is as follows Image 6 Shown; Field emiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com