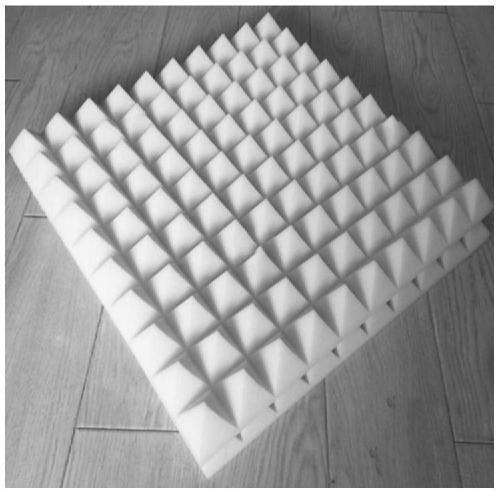

Colored composite pyramid sound-insulation material and preparation method thereof

A technology of sound insulation materials and pyramids, applied in the field of sound insulation materials, can solve the problems of sound wave attenuation, single color of composite materials, etc., and achieve the effect of reducing interference and echo, good permeability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Red Composite Pyramid Soundproofing Material

[0029] Raw materials: Polyurethane (diphenylmethane diisocyanate) 35%, polypropylene fiber 25%, diatomaceous earth 20%, foam stabilizer (BD-3086) 1.5%, foaming agent (AK9005) 10%, colorant (permanent Fast red, golden red, cadmium red (mixed by volume ratio 1:1:1) 2%, aluminate coupling agent 1%, stearic acid 1%, catalyst (dibutyltin dilaurate and triethylenediamine) 0.5 %, surfactant (polyether polyol) 1%, solvent (distilled water, absolute ethanol) 3%, wherein the hardness of polyurethane is 65-72D, and the surface density of polypropylene fiber is 145g / m 2 .

[0030] (1) Diatomite modification: add aluminate coupling agent and 1% absolute ethanol to diatomite and stir thoroughly. After stirring evenly, put stearic acid in for three minutes, and continue to mix fully Then put it into an ultrasonic oscillator to vibrate for 1 hour, take it out and dry it after shaking, the drying temperature is 150°C, and the drying time ...

Embodiment 2

[0035] Yellow Composite Pyramid Soundproofing Material

[0036] Raw materials: polyurethane (diphenylmethane diisocyanate) 30%, polypropylene fiber 27%, diatomaceous earth 21%, foam stabilizer (simethicone) 1%, foaming agent (azodicarbonamide) 10% , coloring agent (permanent yellow, fast yellow G, cadmium yellow mixed in a volume ratio of 2:2:1) 2.5%, aluminate coupling agent 1%, stearic acid 1%, catalyst (dibutyltin dilaurate and triethylenediamine) 0.5%, surfactant (polyether polyol) 1%, solvent 5%, wherein the hardness of polyurethane is 65-72D, and the surface density of polypropylene fiber is 347g / m 2 .

[0037](1) Diatomite modification: add aluminate coupling agent and 2% absolute ethanol to diatomite and stir thoroughly. After stirring evenly, put stearic acid in for three minutes, and continue to mix fully Then put it into an ultrasonic oscillator to vibrate for 2 hours, take it out for drying after shaking, the drying temperature is 200°C, and the drying time is 25...

Embodiment 3

[0042] Purple Composite Pyramid Soundproofing Material

[0043] Raw materials: polyurethane (diphenylmethane diisocyanate) 30%, polypropylene fiber 20%, diatomaceous earth 25%, foam stabilizer (L580) 1.5%, foaming agent (AK9005, azodicarbonamide) 10%, Colorant (manganese violet VM42, permanent violet RL mixed in a volume ratio of 1:3) 2.5%, aluminate coupling agent 1.5%, stearic acid 1%, catalyst (dibutyltin dilaurate and triethylenediamine) 1%, surfactant (polyether polyol) 1.5%, solvent 6%, wherein the hardness of polyurethane is 65-72D, and the surface density of polypropylene fiber is 650g / m 2 .

[0044] (1) Diatomite modification: add aluminate coupling agent and 3% absolute ethanol to diatomite and stir thoroughly. After stirring evenly, put stearic acid in for three minutes, and continue to mix fully Then put it into an ultrasonic oscillator to vibrate for 1-3 hours, take it out for drying after shaking, the drying temperature is 230°C, and the drying time is 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com