Method for electroplating Cr-Ag alloy coating through dication ionic liquid

A technology of ionic liquid and double cation, which is applied in the field of Cr-Ag alloy plating with double cation ionic liquid, can solve problems such as large standard potential difference, difficulty in co-deposition, hydrogen embrittlement hazards, etc. The effect of improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

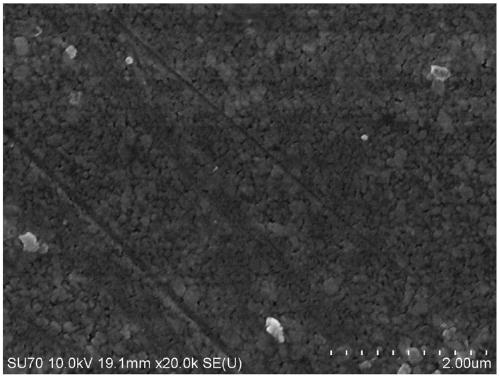

[0047] The invention discloses a method for electroplating a Cr-Ag alloy coating with a double cation ionic liquid, comprising the following steps:

[0048] (1) Substrate pre-treatment; remove oil and rust, wash with water, and dry to obtain the substrate to be deposited;

[0049] (2) Preparation of imidazole-based cation ionic liquids: specifically include the following steps: (a) Synthesis of [BuMImCl]Cl: under nitrogen protection, methylimidazole and 1,4-dichlorobutane in a molar ratio of 1 : 2.1, was added in 100ml of toluene, stirred and refluxed for 6h at 90°C to obtain a pale yellow solid for subsequent use; (b) [BuMIm-TMG]Cl 2 Synthesis: under the protection of nitrogen, [MImBuCl]Cl and tetramethylguanidine were added into 50ml of acetonitrile according to the molar ratio of 1:1.1, and refluxed at 70°C for 15h to obtain the dicationic ionic liquid [BuMIm-TMG]Cl 2 ;

[0050] (3) The preparation of non-aqueous system electroplating solution electroplating solution: acc...

Embodiment 2

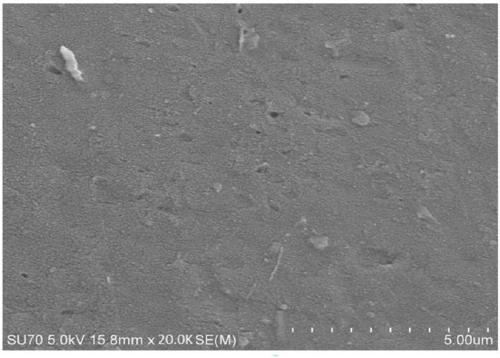

[0056] The invention discloses a method for electroplating a Cr-Ag alloy coating with a double cation ionic liquid, comprising the following steps:

[0057] (1) Substrate pre-treatment; remove oil and rust, wash with water, and dry to obtain the substrate to be deposited;

[0058] (2) Preparation of imidazole-based cation ionic liquids: specifically include the following steps: (a) Synthesis of [BuMImCl]Cl: under nitrogen protection, methylimidazole and 1,4-dichlorobutane in a molar ratio of 1 : 2.05, was added in 100ml toluene, stirred and refluxed for 12h at 80°C to obtain a light yellow solid for subsequent use; (b) [BuMIm-TMG]Cl 2 Synthesis: under the protection of nitrogen, [MImBuCl]Cl and tetramethylguanidine were added into 50ml acetonitrile according to the molar ratio of 1:1.05, and the reflux reaction was carried out at 60°C for 12h, and finally the dicationic ionic liquid [BuMIm-TMG]Cl was obtained. 2 ;

[0059] (3) The preparation of non-aqueous system electropla...

Embodiment 3

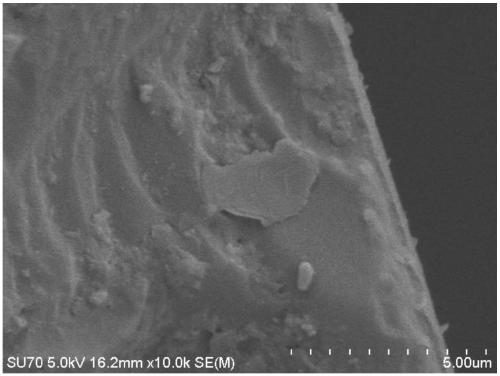

[0064] The invention discloses a method for electroplating a Cr-Ag alloy coating with a double cation ionic liquid, comprising the following steps:

[0065] (1) Substrate pre-treatment; remove oil and rust, wash with water, and dry to obtain the substrate to be deposited;

[0066] (2) Preparation of imidazole-based cation ionic liquids: specifically include the following steps: (a) Synthesis of [BuMImCl]Cl: under nitrogen protection, methylimidazole and 1,4-dichlorobutane in a molar ratio of 1 : 2, was added in 100ml toluene, stirred and refluxed for 9h at 100°C to obtain a pale yellow solid for subsequent use; (b) [BuMIm-TMG]Cl 2 Synthesis: Under the protection of nitrogen, [MImBuCl]Cl and tetramethylguanidine were added into 50ml of acetonitrile according to the molar ratio of 1:1, and the reflux reaction was carried out at 50°C for 18h, and finally the dicationic ionic liquid [BuMIm-TMG]Cl was obtained. 2 ;

[0067] (3) The preparation of non-aqueous system electroplating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com