Nanometer titanium dioxide composite nitrogen-doped carbon nanofibers and preparation method and application thereof

A technology of nano-titanium dioxide and nitrogen-doped carbon, which is applied in secondary batteries, electrochemical generators, electrical components, etc., can solve the problems of slow battery reaction kinetics, affecting battery performance, and volume expansion of positive electrode materials, etc. Lithium sulfide shuttle effect, stable cycle performance, and the effect of increasing adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

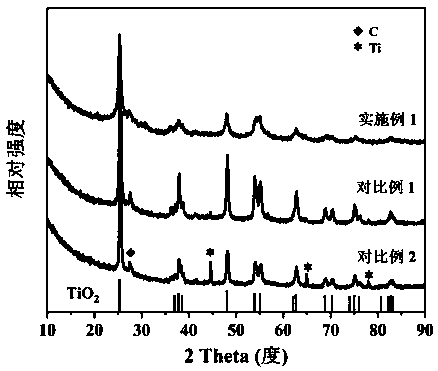

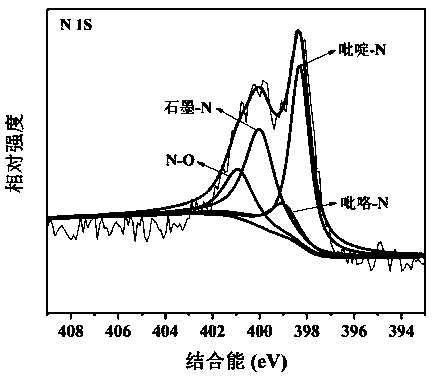

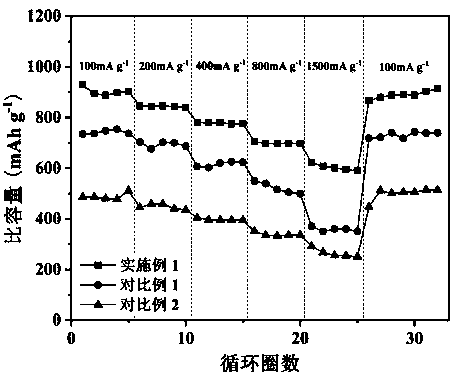

[0036] A nano-titanium dioxide composite nitrogen-doped carbon nanofiber is prepared by the following method:

[0037] (1) Prepare 18 mL of N,N-dimethylformamide solution containing acrylonitrile, in which the mass volume concentration of acrylonitrile is 0.0756 g·ml-1 ;

[0038] (2) Add 2.5 mL of tetrabutyl titanate to the solution obtained in (1) and continue stirring for 10 min to obtain a uniformly dispersed white emulsion;

[0039] (3) Pour the precursor solution obtained in (2) into a 20 mL syringe, install a No. 20 needle and place it in the electrospinning device; the conditions for electrospinning are: the electric field strength is 1.67 KV cm -1 , the heating temperature is 60°C, and the advancing speed is 1.2 mL·h -1 advance speed.

[0040] (4) Put the precursor fiber obtained in (3) in a corundum crucible, and heat it in a tube furnace at 5°C min -1 The heating rate is heated to 280 ° C for 2 h; -1 The heating rate was heated to 700°C for 2 h for carbonization;...

Embodiment 2

[0042] The preparation process of the nano-titanium dioxide composite nitrogen-doped carbon nanofiber provided in this example is the same as that in Example 1, except that the carbonization temperature used is 750°C.

[0043] Example 2

[0044] The preparation process of the nano-titanium dioxide composite nitrogen-doped carbon nanofiber provided in this example is the same as in Example 1, except that the tetrabutyl titanate used is 2 mL, that is, the tetrabutyl titanate in the white emulsion in step (2) The volume fraction of butyl ester is 11.11%.

Embodiment 3

[0046] The preparation process of the nano-titanium dioxide composite nitrogen-doped carbon nanofiber provided in this example is the same as in Example 1, except that the tetrabutyl titanate used is 3 mL, that is, the tetrabutyl titanate in the white emulsion in step (2) The volume fraction of butyl ester is 16.67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com