Ternary interpenetrating polymer network structure paint and preparation method thereof

A technology of interpenetrating polymer and network structure, applied in the field of ternary interpenetrating polymer network structure coating and its preparation, can solve the problem of low water resistance, poor compatibility and compatibility, poor long-term anti-corrosion performance of water-based anti-corrosion coatings, etc. problems, to achieve the effect of improving water resistance, improving overall performance, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

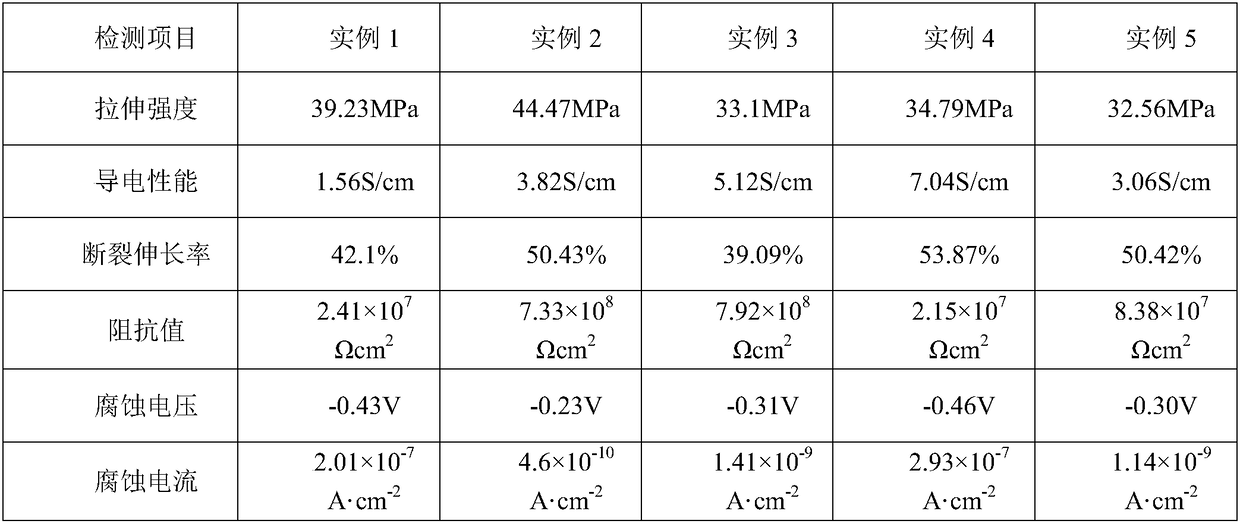

Examples

preparation example Construction

[0028] The method for preparing a ternary interpenetrating polymer network structure coating of the present invention has the following specific steps:

[0029] a. Weigh 100 parts of 10% polyvinyl alcohol (PVA) solution and 4-8 parts of glycidyl methacrylate, add them to a 250ml three-necked flask, raise the temperature to 60-90℃, and stir until it forms Transparent and colorless solution; then slowly add acid, adjust the pH value to 1~2, add dropwise cerium ammonium nitrate solution, continue the reaction for 2~3h, then you can prepare glycidyl methacrylate modified PVA solution (GPVA) .

[0030] b. Add 2-6 parts of aniline dropwise to 100 parts of GPVA solution with a mass fraction of 10%, and react at 50-70° C. for 2 to 3 hours to prepare the aniline grafted modified GPVA dispersion.

[0031] c. Reduce the temperature of the aniline graft modified GPVA dispersion system to 0~5℃, add an acid solution to adjust the pH of the system to 1~2, and then add a metered oxidant to initiate...

Embodiment 1

[0036] a. Weigh 100 parts of 10% polyvinyl alcohol (PVA0588) aqueous solution and 5 parts of glycidyl methacrylate, add them to a 250ml three-necked flask, raise the temperature to 80℃, and stir until a transparent colorless solution is formed ; Then slowly add hydrochloric acid solution, adjust the pH to 1, dropwise add cerium ammonium nitrate solution, continue to react for 3h, you can prepare glycidyl methacrylate modified PVA solution (GPVA).

[0037] b. Add 3 parts of aniline dropwise to 100 parts of GPVA solution with a mass fraction of 10%, and react at 60° C. for 2 hours to prepare the aniline graft modified GPVA dispersion.

[0038] c. Reduce the temperature of the aniline grafted modified GPVA dispersion system to 0°C, add hydrochloric acid solution to adjust the pH of the system to 1, and then dropwise add an oxidant to initiate the redox reaction of aniline. The molar ratio of oxidant to aniline is 1, and react The dispersion of polyaniline grafted modified GPVA (PANI-G...

Embodiment 2

[0042] a. Weigh 100 parts of 10% polyvinyl alcohol (PVA1099) solution and 4 parts of glycidyl methacrylate, add them to a 250ml three-necked flask, raise the temperature to 80℃, and stir until a transparent colorless solution is formed ; Then slowly add nitric acid solution, adjust the pH value to 1, dropwise add cerium ammonium nitrate solution, continue to react for 3h, you can prepare glycidyl methacrylate modified PVA solution (GPVA).

[0043] b. Add 4 parts of aniline dropwise to 100 parts of GMA-PVA solution with a mass fraction of 10%, and react at 70° C. for 2.5 hours to prepare the aniline graft modified GPVA dispersion.

[0044] c. Reduce the temperature of the aniline graft modified GPVA dispersion system to 5°C, add sodium dodecylbenzene sulfonate solution to adjust the pH of the system to 2, and then add a metered oxidant ferric chloride to initiate the oxidation of aniline In the reduction reaction, the molar ratio of the oxidant to the aniline is 1.5, and the polyani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com