Application of tannic acid serving as micro-contact printing ink to cell patterning

A technology of micro-contact printing and cell patterning, applied in the field of cell culture, can solve problems such as time-consuming and opaque patterns, and achieve the effects of simple steps, low price and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

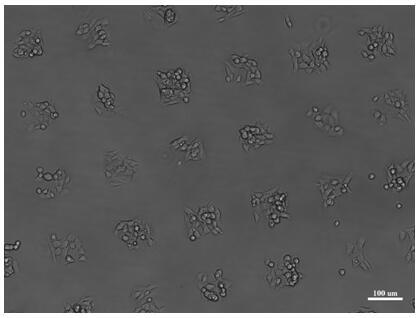

[0037] Printing of Tannic Acid Patterns on the Surface of Polyethylene Glycol Silane Modified Quartz Chips

[0038] 1. Oxidize the quartz sheet

[0039] Quartz sheet (8*8*0.5 mm 3 , purchased from Donghai County Weida Quartz Products Co., Ltd.) in acetone and absolute ethanol for 10 minutes of ultrasonic cleaning, then boiled in a mixture of concentrated sulfuric acid and hydrogen peroxide (volume ratio 3:1) for 1 hour, and cleaned with ultrapure water. blow dry. The quartz slice was oxidized in a low-temperature plasma processor for 6 min.

[0040] 2. Inert modification of quartz slices

[0041] The oxidized quartz slice was soaked in 6 g / L methoxypolyethylene glycol silane (MW2000) in toluene solution for 24 h, and 1% triethylamine was added as a catalyst. After the reaction was completed, wash 2 times with absolute ethanol, wash 2 times with ultrapure water, N 2 Blow dry and store in N 2 atmosphere.

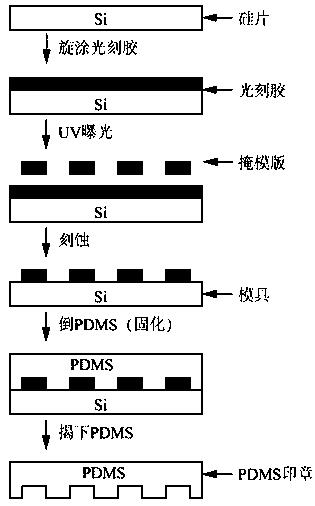

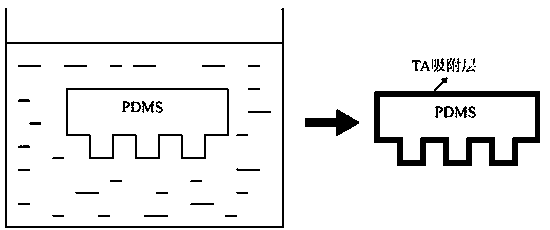

[0042] 3. Preparation of polydimethylsiloxane stamp

[0043] Firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com