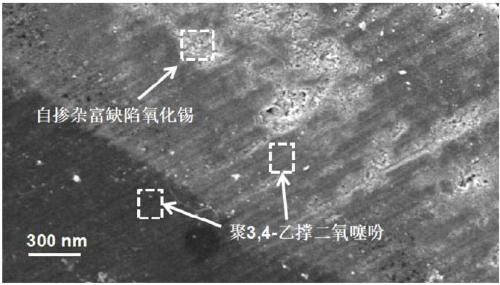

Preparation method of poly(3,4-ethylenedioxythiophene)/self-doped defect-rich tin oxide nano composite photocatalytic material

A technology of ethylenedioxythiophene and photocatalytic materials, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of obvious material agglomeration effect and reaction raw materials Insufficient environmental and friendly problems, to achieve the effect of simple process control, high efficiency and stable photocatalytic performance, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Get 1mmol analytically pure stannous pyrophosphate (Sn 2 P 2 o 7 ) and 1.5mmol of acetic acid (CH 3 COOH), fully dissolved in 5mL of absolute ethanol, and then added successively 0.5mmol of alkyl dimethyl hydroxypropyl phospholipid betaine, 2mmol of tea polyphenols and 13mL of deionized water. In the ice-salt bath of crushed ice, use a constant temperature magnetic stirring device to continuously magnetically stir it at -10°C until it is completely dissolved to obtain solution A;

[0029] 2) Transfer solution A to a polytetrafluoroethylene-lined hydrothermal kettle at a filling ratio of 70%, then put the reaction kettle into a constant temperature oven at 120°C for 24h, after the hydrothermal reaction is completed, cool to room temperature to obtain Mixture B of self-doping defect-rich tin oxide heterojunction;

[0030] 3) Under the condition of continuous magnetic stirring in an ice bath of sodium chloride and crushed ice at -10°C, control 3,4-ethylenedioxythiop...

Embodiment 2

[0033] 1) Get 1mmol analytically pure stannous pyrophosphate (Sn 2 P 2 o 7 ) and 2.8mmol of acetic acid (CH 3 COOH), fully dissolved in 9mL of absolute ethanol, and then sequentially added 5mmol of alkyl dimethyl hydroxypropyl phospholipid betaine, 7mmol of tea polyphenols and 20mL of deionized water. In the ice-salt bath, use a constant temperature magnetic stirring device to continuously magnetically stir it at -5°C until it is completely dissolved to obtain solution A;

[0034] 2) Transfer the solution A to a polytetrafluoroethylene-lined hydrothermal kettle with a filling ratio of 66%, then put the reaction kettle into a constant temperature oven and keep it warm at 170°C for 12h. After the hydrothermal reaction is completed, cool to room temperature to obtain Mixture B of self-doping defect-rich tin oxide heterojunction;

[0035] 3) Under the condition of continuous magnetic stirring in an ice bath of sodium chloride and crushed ice at -5°C, control 3,4-ethylenedioxyt...

Embodiment 3

[0039] 1) Get 1mmol analytically pure stannous pyrophosphate (Sn 2 P 2 o 7 ) and 3.6mmol of acetic acid (CH 3 COOH), fully dissolved in 16mL of absolute ethanol, and then sequentially added 8mmol of alkyl dimethyl hydroxypropyl phospholipid betaine, 15mmol of tea polyphenols and 23mL of deionized water. In the ice-salt bath, use a constant temperature magnetic stirring device to continuously magnetically stir it at 10°C until it is completely dissolved to obtain solution A;

[0040] 2) Transfer the solution A to a polytetrafluoroethylene-lined hydrothermal kettle at a filling ratio of 35%, and then put the reaction kettle into a constant temperature oven at 200°C for 1 hour. After the hydrothermal reaction is completed, cool to room temperature to obtain Mixture B of self-doping defect-rich tin oxide heterojunction;

[0041] 3) Under the condition of continuous magnetic stirring in an ice bath of sodium chloride and crushed ice at 10°C, control 3,4-ethylenedioxythiophene (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com