Porous lithium-ion battery separator based on cross-linked and linear polymers and its preparation method and application

A lithium-ion battery and porosity technology, which is applied in the field of porous lithium-ion battery diaphragm preparation, can solve problems such as excessive pore size, weakened mechanical properties of the diaphragm, and uneven pore size distribution, and achieve increased absorption, excellent dimensional stability, and mechanical properties. good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

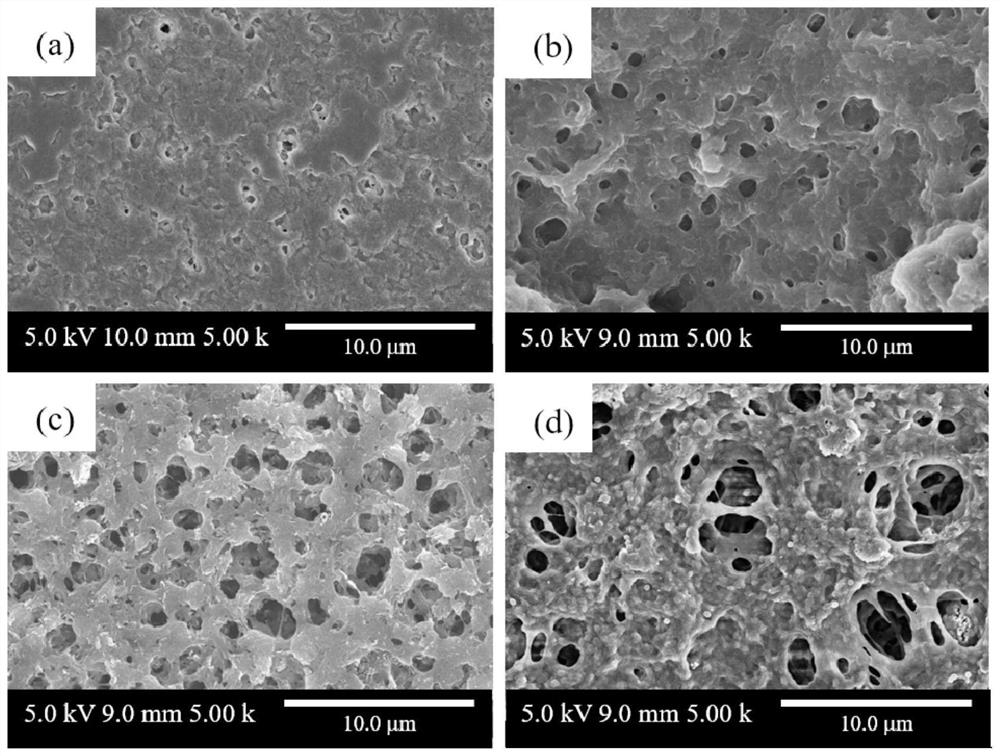

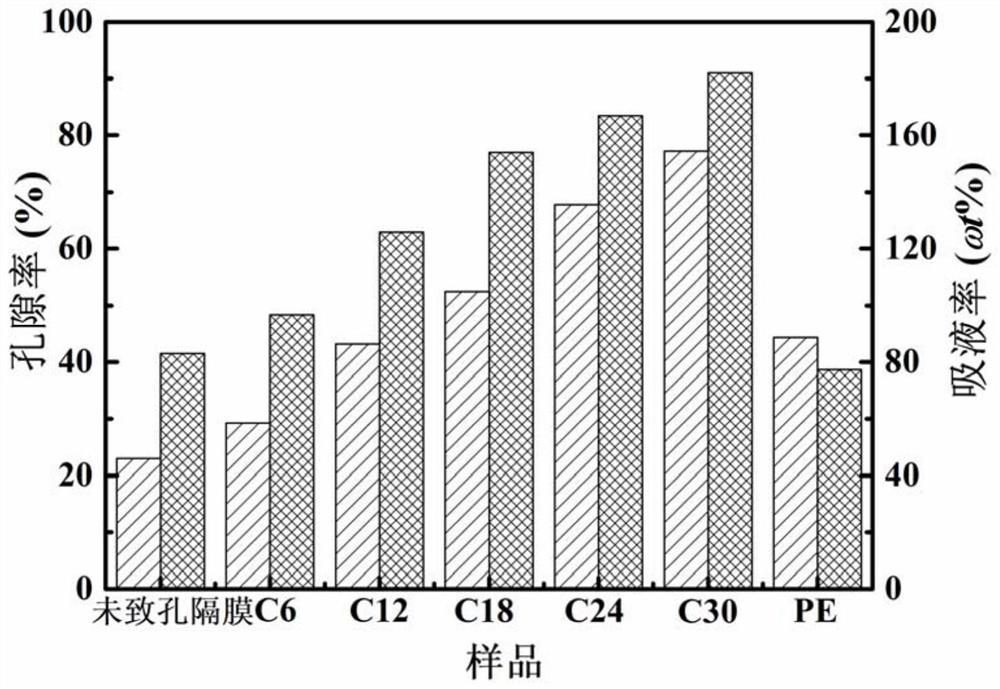

[0050] Example 1: Preparation of porous lithium-ion battery separator based on cross-linked and linear polymers using nano-ZnO with different particle sizes as porogens

[0051] Weighed 2.0 g PVDF-HFP, 0.15 g OV-POSS, and 0.36 g nano-ZnO, put them into a mixed solvent of 10 g DMF and 5 g THF, and stirred at room temperature for 12 h to form a uniform solution. Add 0.7 g PEGMEMA and 0.35 g MMA and continue stirring for 2 h. Finally, 0.149 g DMPA was added and stirred for 20 min until it was completely dissolved; after standing for defoaming, the solution was evenly coated on a clean and flat polyethylene plate with an adjustable film applicator; finally, the polyethylene plate coated with the solution was placed on the The polymerization was initiated under ultraviolet light, and then dried in a vacuum oven at 70 °C for 12 h to remove the solvent. The separator was taken out and soaked in PC for 12 h, then soaked in dilute hydrochloric acid for 2 h, then ultrasonically cleaned...

Embodiment 2

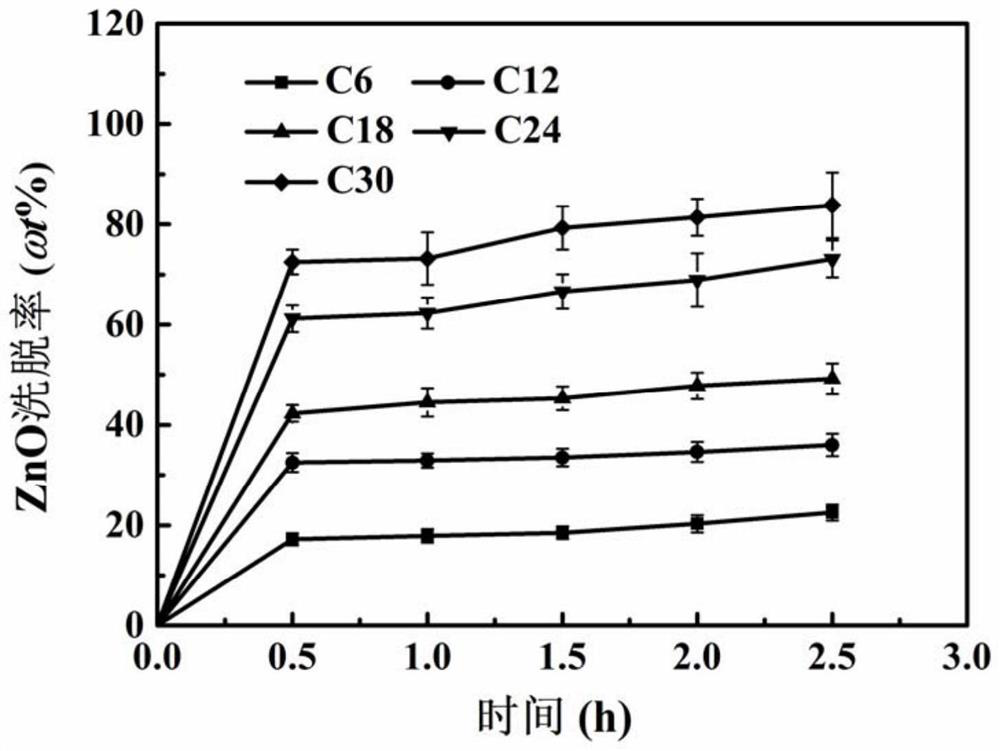

[0052] Example 2: Preparation of porous lithium-ion battery separator based on cross-linked and linear polymers with different additions of nano-ZnO as porogen

[0053] Weigh 2.0 g PVDF-HFP, 0.15 g OV-POSS, according to the theoretical mass of nano-ZnO accounting for PVDF-HFP, add a certain mass of nano-ZnO with a particle size of 30 nm, and put it into a mixed solvent of 10 g DMF and 5 g THF, Stirred at room temperature for 12h to form a homogeneous solution. Add 0.7 g PEGMEMA and 0.35 g MMA and continue stirring for 2 h. Finally, 0.149 g DMPA was added and stirred for 20 min until it was completely dissolved; after standing for defoaming, the solution was evenly coated on a clean and flat polyethylene plate with an adjustable film applicator; finally, the polyethylene plate coated with the solution was placed on the The polymerization was initiated under ultraviolet light, and then dried in a vacuum oven at 70 °C for 12 h to remove the solvent. The separator was taken out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com