A continuous crystallization device and method for spheroidizing large-particle ammonium perchlorate

A kind of ammonium perchlorate, spheroidization technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

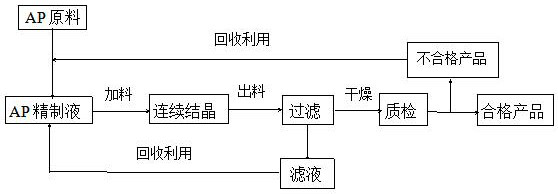

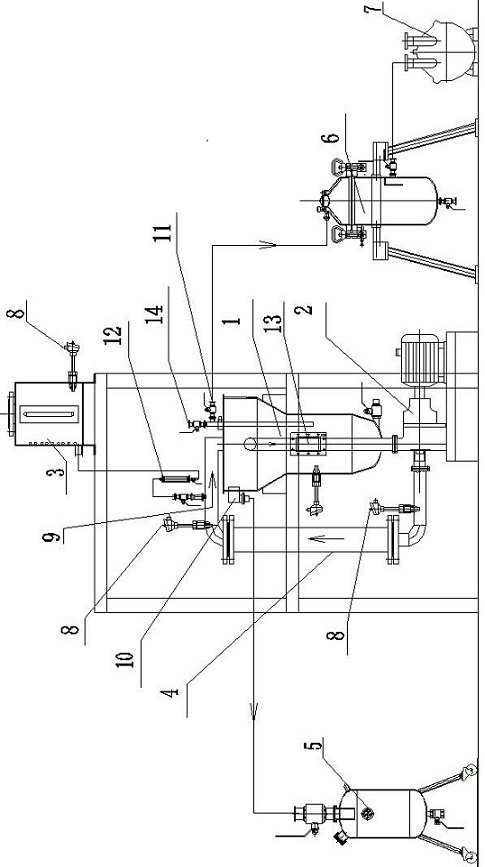

Method used

Image

Examples

Embodiment 1

[0047] (1) Connect the cooling water of the crystallization heat exchanger (condenser);

[0048] (2) Feed into the crystallizer (approximately 50-80 liters of 20-30 ℃ AP saturated solution) until there is overflow at the overflow port;

[0049] (3) Feed the refined liquid raw material tank (about 10-20 liters of 50-80 ℃ AP saturated solution), and turn on the heating power;

[0050] (4) Turn on the power of the material circulation pump, run for 2-3 minutes, and operate according to the process requirements: the feeding amount of AP saturated solution is 500.00 mL / h; the flow rate of the material circulation system is 180L / h; the cycle time is 3.5h. Open the feed metering valve at the lower part of the refined liquid raw material tank, and white ammonium perchlorate crystals are precipitated during the material circulation process. By controlling the feeding and circulation flow in the lower part of the raw material tank, observe the material circulation, the formation of the...

Embodiment 2

[0059] (1) Connect the cooling water of the crystallization heat exchanger (condenser);

[0060] (2) Feed into the crystallizer (approximately 50-80 liters of 20-30 ℃ AP saturated solution) until there is overflow at the overflow port;

[0061] (3) Feed the refined liquid raw material tank (in the heating storage tank) (about 10-20 liters of 50-80 ℃ AP saturated solution), and turn on the heating power;

[0062] (4) Turn on the power supply of the material circulation pump, run for 2-3 minutes, and the feeding volume of the AP saturated solution is 500.00 mL / h; adjust the circulation flow rate from small to large, and adjust the flow rate of the material circulation system from 180 L / h to 250.00L / h; cycle time 3.5h. Open the feeding metering valve at the lower part of the raw material tank of the supersaturated liquid, and white ammonium perchlorate crystals are precipitated during the material circulation process. Observe the material circulation, the formation of the cryst...

Embodiment 3

[0066] (1) Connect the cooling water of the crystallization heat exchanger (condenser);

[0067] (2) Add material to the crystallizer (approximately 50-80 liters of 20-30°C AP saturated solution) until the material overflows at the overflow port;

[0068] (3) Feed the refined liquid raw material tank (in the heating storage tank) (about 10-20 liters of 50-80°C AP saturated solution), and turn on the heating power;

[0069] (4) Turn on the power of the material circulation pump and run it for 2-3 minutes. The feed volume of AP saturated solution is 500.00 mL / h; the flow rate of the material circulation system is 250.00L / h; adjust the cycle time for 5-7.5 hours. Open the feeding metering valve at the lower part of the raw material tank of the supersaturated liquid, and white ammonium perchlorate crystals are precipitated during the material circulation process. By controlling the feeding and circulation flow in the lower part of the raw material tank, observe the material circu...

PUM

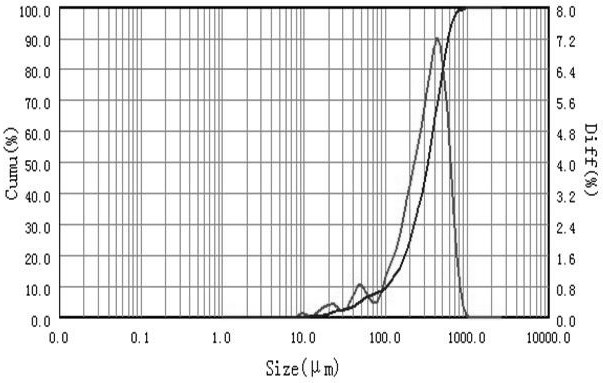

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com