Chitosan-modified activated coke in-situ loaded nano-gold catalyst and its preparation method

A technology of activated coke and chitosan, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, preparation of organic compounds, etc., can solve catalyst activity decline, environmental secondary pollution, nano-gold Poor dispersion and other problems, to achieve the effect of improving mechanical stability, stable chemical properties, and developed void structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

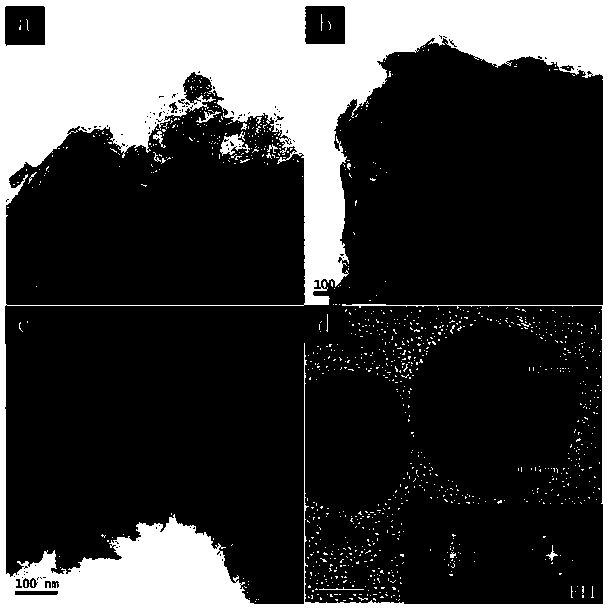

[0037] A chitosan-modified activated coke in-situ supported nano-gold catalyst, including activated coke, chitosan and nano-gold particles, wherein the chitosan modification forms a chitosan / active coke complex on the surface of the active coke, and the chitosan / The active coke composite is loaded with nano-gold particles.

[0038] In this example, in the chitosan-modified activated coke in-situ loaded nano-gold catalyst, the mass percentage of nano-gold particles was 0.84 wt%, and the mass ratio of chitosan to activated coke was 0.5.

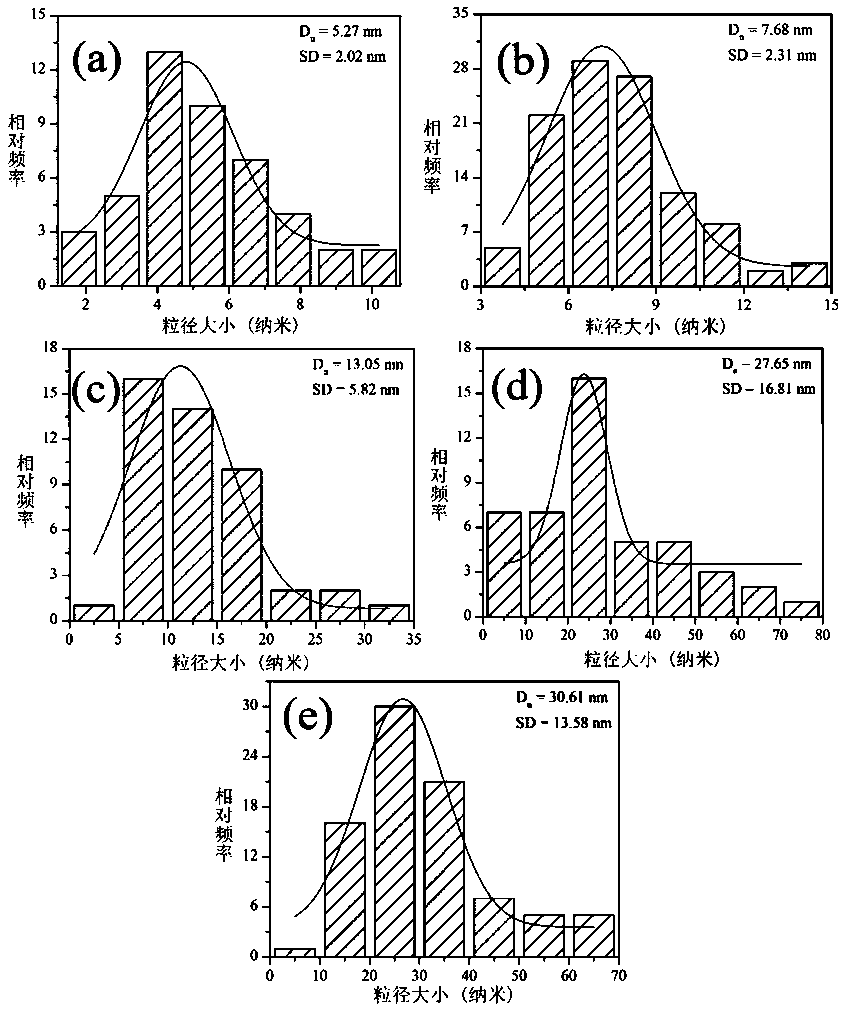

[0039] In this embodiment, the average particle size of the gold nanoparticles is 5.27 ± 2.02 nm.

[0040] A kind of preparation method of the above-mentioned chitosan modified active coke in situ loaded nano-gold catalyst of the present embodiment, comprises the following steps:

[0041] (1) Pretreatment of active coke:

[0042] The active coke was cleaned with ultrapure water, and dried in a vacuum drying oven; the dried active coke was ba...

Embodiment 2

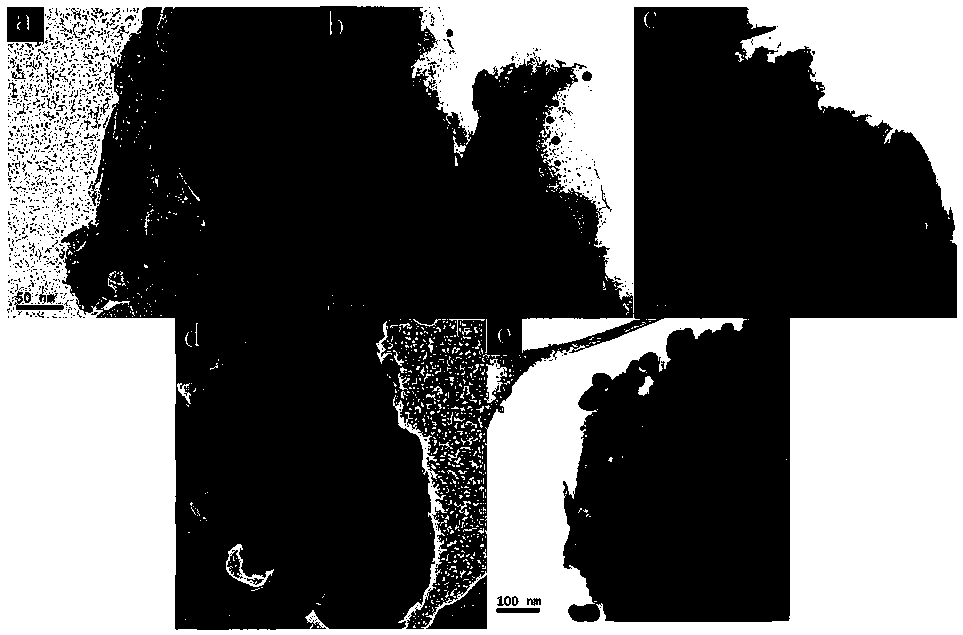

[0051] A chitosan-modified active coke in-situ loaded nano-gold catalyst is basically the same as the chitosan-modified active coke in-situ loaded nano-gold catalyst in Example 1, the only difference being: Chitosan-modified active coke in Example 2 The mass percentage of gold nanoparticles in the in situ supported nano-gold catalyst was 1.68 wt%, and the average particle size of gold nanoparticles was 6.78 ± 2.31 nm.

[0052] A kind of preparation method of the above-mentioned chitosan modified active coke in-situ loading nano-gold catalyst of the present embodiment is basically the same as the preparation method of embodiment 1, the difference is only: the input of chloroauric acid solution in the preparation method of embodiment 2 The dosage is 0.7mL.

[0053] The chitosan-modified active coke prepared in Example 2 supported nano-gold catalyst in situ, numbered as Au NPs / CTS / AC (2) .

Embodiment 3

[0055] A chitosan-modified active coke in-situ loaded nano-gold catalyst, which is basically the same as the chitosan-modified active coke in-situ loaded nano-gold catalyst in Example 1, the only difference being: Chitosan-modified active coke in Example 3 The mass percentage of gold nanoparticles in the in situ loaded nano-gold catalyst was 3.35 wt%, and the average particle size of gold nanoparticles was 13.05 ± 5.82 nm.

[0056] A kind of preparation method of the above-mentioned chitosan modified activated coke in-situ loading nano-gold catalyst of the present embodiment is basically the same as the preparation method of embodiment 1, the difference is only: the input of chloroauric acid solution in the preparation method of embodiment 3 The dosage is 1.4mL.

[0057] The chitosan-modified active coke prepared in Example 3 supports nano-gold catalyst in situ, and the number is Au NPs / CTS / AC (3) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com