Grass suppression straw biomass-base degradable mulching film and application

A technology for degrading mulch film and straw biology, which is applied in the fields of application, plant protection, plant protection cover, etc., can solve the problem of not being able to fully utilize straw components, and achieve the effects of reduced energy consumption, favorable market promotion, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Synthesis of alkenyl succinic anhydride grafted starch adhesive

[0043] Synthesis of alkenyl succinic anhydride grafted starch adhesive: mix 2000g of water and 1000g of cornstarch at room temperature, put them in a reaction kettle, gelatinize the starch for 2 hours at 55°C, and use 20% hydrogen Adjust the pH value of the sodium oxide solution to 9, raise the temperature to 65°C, add 1g of ferrous sulfate, stir evenly, add 6g of hydrogen peroxide, oxidize for 1h, add 20g of polyvinyl alcohol and 15g of alkenyl succinic anhydride to carry out graft polymerization, and react at 85°C for 1h Finally, add 0.5g of borax for cross-linking, cool down to room temperature after 30min, and discharge.

[0044] Among them, polyvinyl alcohol needs to be dissolved into a transparent solution with a mass fraction of 12.5% at 95°C before use.

[0045] The performance indicators of the alkenyl succinic anhydride grafted starch adhesive synthesized in this example are as foll...

Embodiment 2

[0046] Example 2 Preparation of Straw Biomass Base Film

[0047] The preparation method is as follows:

[0048] S1: straw biological pretreatment

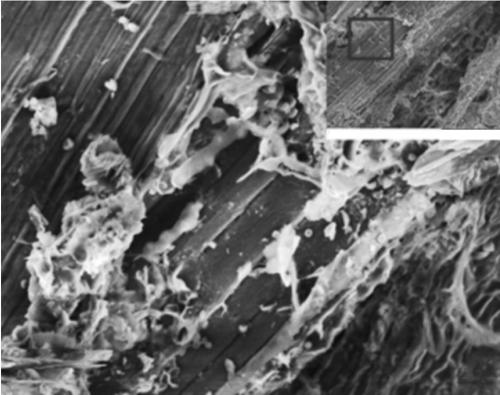

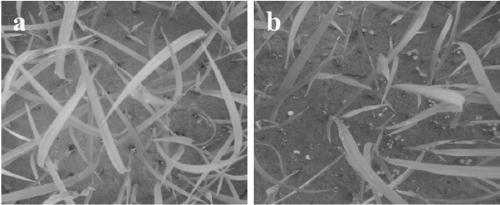

[0049] Crush 1000g of rice straw into short stems with a length of 2-5cm, air-dry them naturally (with a moisture content of about 12%), inoculate 910mg of Phanerochaete chrysosporium mycelium and 390mg of Streptomyces loucherii mycelium into the rice straw On the fiber, urea is used to adjust the carbon-nitrogen ratio of the material system to 30:1, and the moisture content is 65%, and it is evenly mixed; it is aerobically fermented in a solid fermenter for 10 days, and the pile is turned every 2 days during the fermentation period. After the fermentation is completed, the pretreated rice straw fiber is obtained, and its SEM photo is as follows: figure 1 shown.

[0050] In the specific implementation process, the fresh weight ratio of Phanerochaete chrysosporium and Streptomyces loucherii mycelia can be controlled between 1 an...

Embodiment 3

[0056] Example 3 Preparation of Straw Biomass Base Film

[0057] The preparation method is as follows:

[0058] S1: straw biological pretreatment, the same as in Example 2;

[0059] S2: Straw fiber softening and dismantling and separation, the same as in Example 2;

[0060] S3: Preparation of straw fiber mulch

[0061] Mix 240g of dismantled straw fibers from step S2 with 60g of wood pulp, add in batches to a Valli beater with 18kg of water, add 15g of methylcellulose, 0.6g of sodium alginate, 6g of gelatin, and 4.5g of polyamide Epichlorohydrin resin, 0.6g alkyl ketene dimer, 0.3g polyacrylamide, 9g glycerol, 15g alkenyl succinic anhydride grafted starch adhesive, 1.5g biochar, 1.5g nano tourmaline powder, Stir homogeneously until the beating degree is 38±1°SR. After being dehydrated and dried by a dehydrator, it is formed into a straw biomass base film, numbered RSFM-Ⅱ.

[0062] In the specific implementation process, the amount of nano tourmaline powder can be 0.5~3% (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com