Production method of carbon vanadium nitride solid melt and hard alloy thereof

A vanadium-titanium carbonitride and vanadium-titanium carbonitride-based technology, which is applied in the field of cemented carbide, can solve the problems of complex nitrogen partial pressure and flow rate, increase production cost, and nitrogen content exceeding the standard, and achieve easy control and operation of nitrogen content. Easy-to-control, simple-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

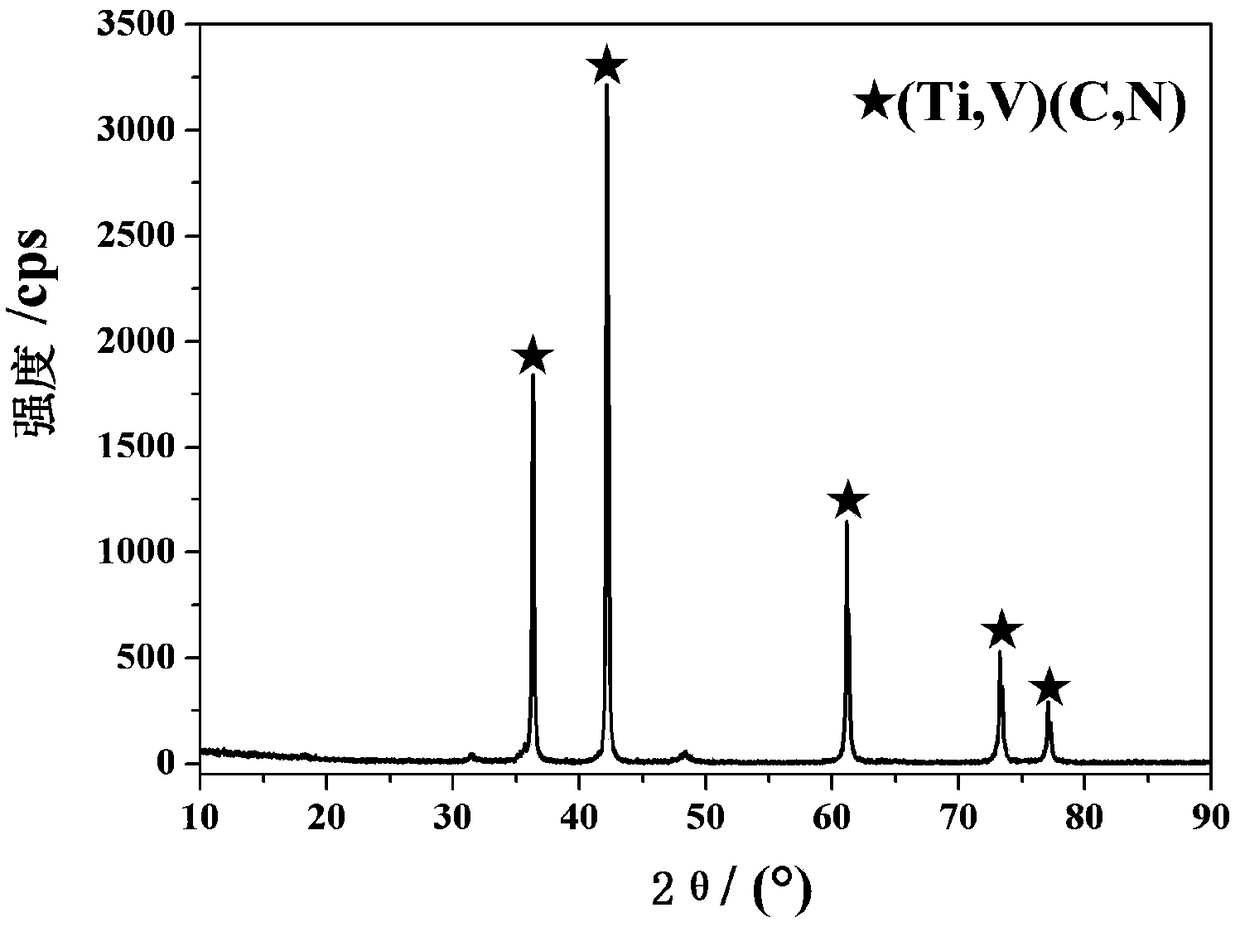

[0078] Take 44.14 grams of Ti(C,N) (solid solution formed by 30.53% TiC and 69.14% TiN) powder, and 55.86 grams of (Ti,V)C (solid solution formed by 99.96% TiC and 0.03% VC), Mix with absolute ethanol at a liquid-solid ratio of 6:1, and perform ball milling at a ball-to-material ratio of 8:1. The ball mill slurry is poured out from the ball mill, and at the same time passed through a sieve with an aperture of 0.05 mm for clarification, and the oversize is returned to the second batch of ball mills. After pouring out the supernatant liquid, dry it at a vacuum of 0.3 Pa at a temperature of 70° C. for 7 hours, and volatilize the ethanol therein to obtain a mixture. Compress the mixture to a density of 3.2g / cm 3 of compacts. Place the compact in a vacuum furnace at a vacuum degree of 6×10 -2 Pa, alloying at a temperature of 1600°C for 3 hours, cooling down to room temperature, breaking the vacuum, opening the vacuum furnace, and taking out the alloyed compact. After crushing t...

Embodiment 2

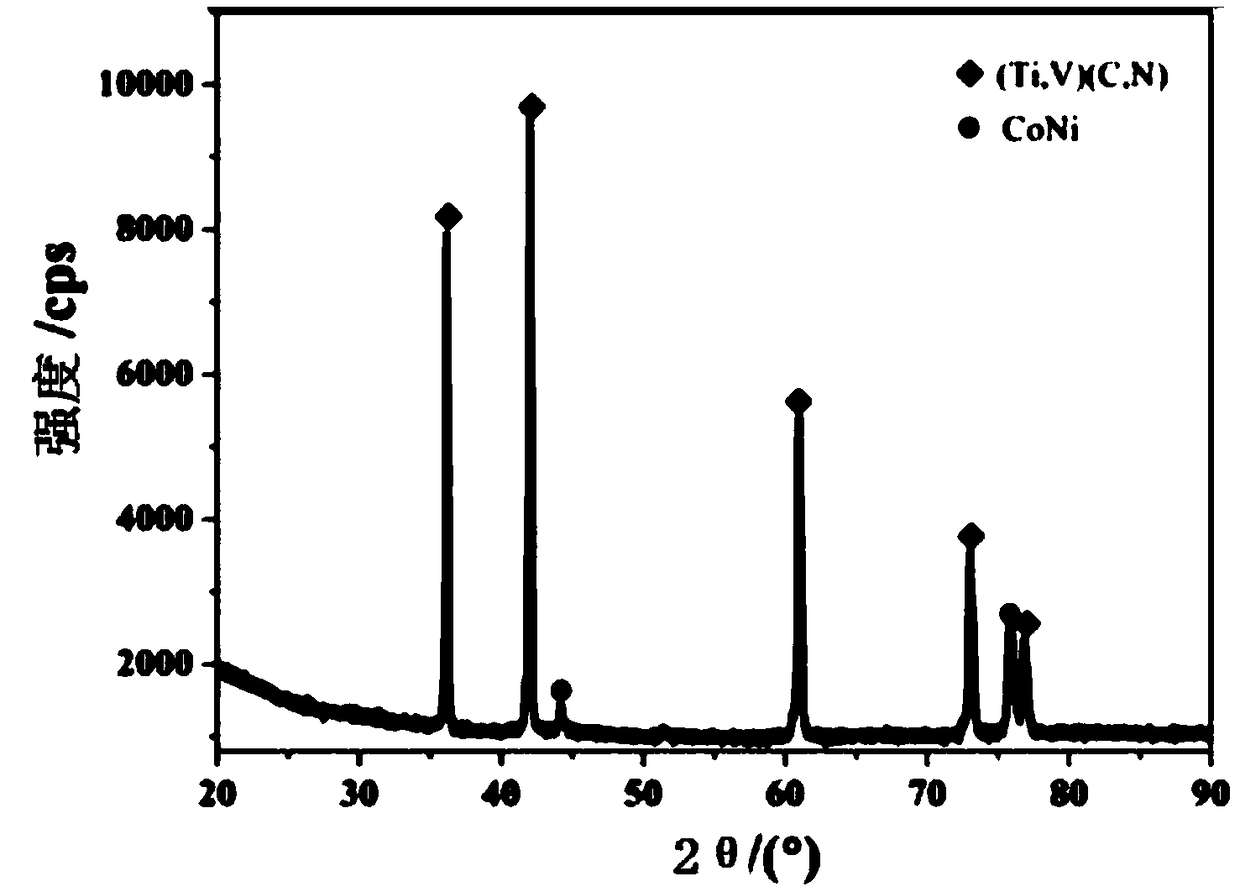

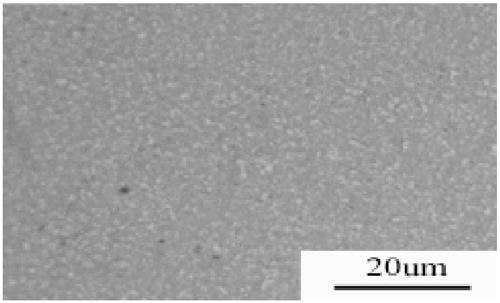

[0080] Take 13.52 grams of Ti(C,N) (solid solution formed by 30.53% TiC and 69.14% TiN) powder, and 86.48 grams of (Ti,V)C (solid solution formed by 99.96% TiC and 0.03% VC), 14 grams of Co powder and 6 grams of Ni powder were mixed with absolute ethanol at a liquid-solid ratio of 4:1, and the ball-to-material ratio was 5:1 for ball milling, and the ball milling time was 72 hours. The ball mill slurry is poured out from the ball mill, and passed through a 0.04-diameter sieve for clarification, and the oversize is returned to the second batch of ball mills. After pouring out the supernatant liquid, dry it at a vacuum of 0.2 Pa at a temperature of 70° C. for 8 hours, and volatilize the ethanol therein to obtain a mixture. According to the ratio of 120 grams of SD-2X rubber per kilogram, mix the mixture with the gasoline solution of SD-2X rubber evenly, and the concentration of the gasoline rubber solution is 0.024g / cm 3 . The mixture mixed with glue was dried in a vacuum atmosph...

Embodiment 3

[0082] Take V(C,N) (a solid solution composed of 34.03% VN and 65.97% VC) 82.97 grams, take (Ti, V)C (a solid solution formed by 79.22% TiC and 20.78% VC) 17.03 grams, Mix with absolute ethanol at a liquid-to-solid ratio of 8:1, ball milling with a ball-to-material ratio of 10:1, and the ball milling time is 24 hours. The ball mill slurry is poured out from the ball mill, and passed through a 0.04-aperture sieve for clarification at the same time, and the sieved material is returned to the second batch of ball mills. After pouring out the supernatant liquid, dry it at 80° C. for 6 hours at a vacuum degree of 0.5 Pa, and volatilize the ethanol therein to obtain a mixture. Compress the mixture to a density of 3.8g / cm 3 of compacts. The compact was placed in a tube furnace and kept warm under an argon atmosphere at a temperature of 1900°C for 6 hours for alloying. Open the door of the tube furnace and take out the alloyed compact. After crushing the compact, pass through a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com