A method for connecting aluminum nitride ceramic plate and metal based on PVD deposition method

A technology of aluminum nitride ceramics and a deposition method, which is applied in the field of ceramic metallization, can solve the problems of reducing the thermal conductivity of aluminum nitride ceramic plates and cumbersome processes, and achieves less solder overflow, controllable materials, and simple control conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

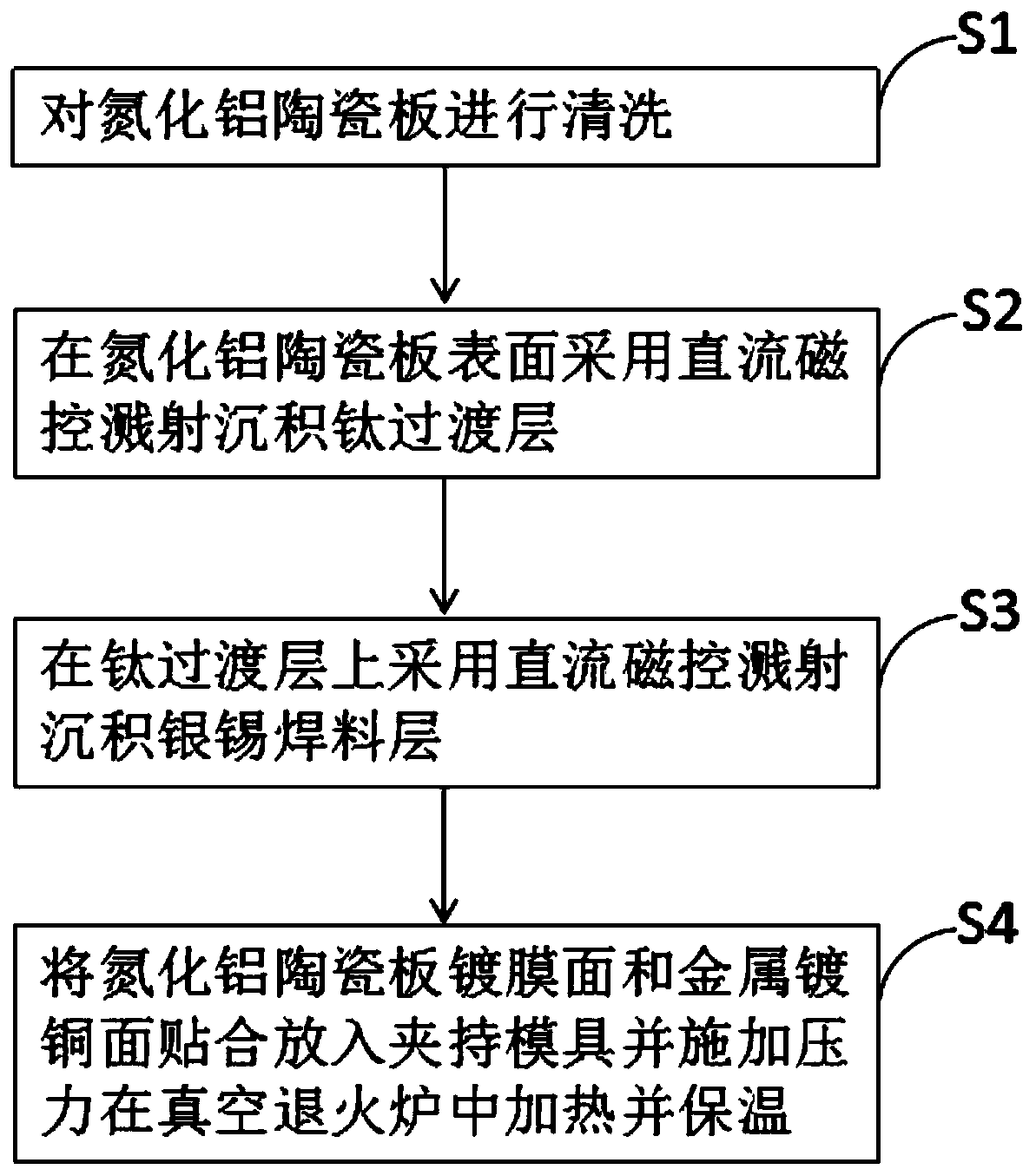

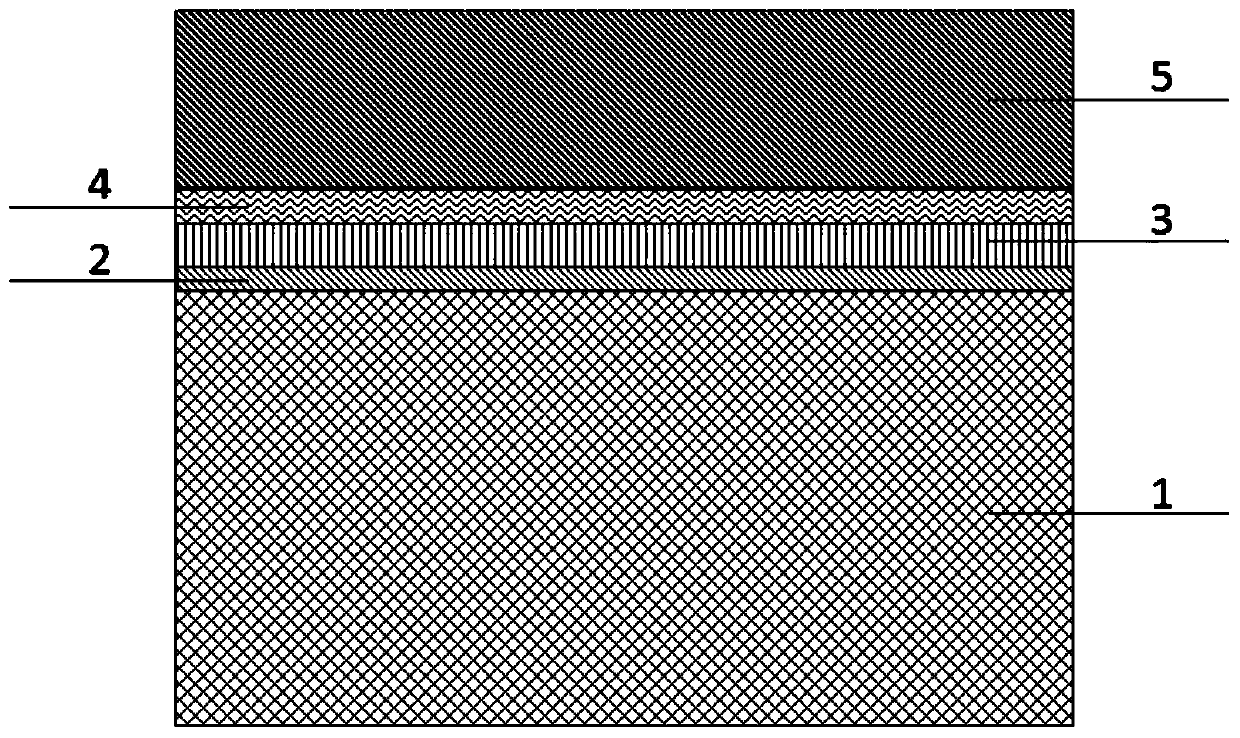

[0038] like figure 1 As shown, the method for connecting aluminum nitride ceramic plate and metal based on PVD deposition method comprises the following steps:

[0039] Step 1, cleaning the aluminum nitride ceramic plate: after soaking in absolute ethanol, ultrasonically in acetone and absolute ethanol for 10-15 minutes, after drying, use radio frequency plasma cleaning in the magnetron sputtering chamber for 20 minutes ~30min;

[0040] Step 2, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass in argon gas with a purity of 99.99%, the air flow is 20sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 130W for titanium with a purity of 99.99% Plasma cleaning is performed on the target surface for 15 minutes, then the base negative bias is applied -50V, then the titanium target baffle is opened, the sample baffle is opened, and the sputter deposition is started, and the sample baffle and the titanium target baffle a...

Embodiment 2

[0044] like figure 1 As shown, the method for connecting aluminum nitride ceramic plate and metal based on PVD deposition method comprises the following steps:

[0045] Step 1, cleaning the aluminum nitride ceramic plate: after soaking in absolute ethanol, ultrasonically in acetone and absolute ethanol for 10-15 minutes, after drying, use radio frequency plasma cleaning in the magnetron sputtering chamber for 20 minutes ~30min;

[0046] Step 2, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass in argon gas with a purity of 99.99%, the air flow is 30sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 150W for titanium with a purity of 99.99% Plasma cleaning is performed on the target surface for 20 minutes, then the base negative bias is applied to -70V, then the titanium target baffle is opened, the sample baffle is opened, and the sputtering deposition is started, and the sample baffle and the titanium target ba...

Embodiment 3

[0050] like figure 1 As shown, the method for connecting aluminum nitride ceramic plate and metal based on PVD deposition method comprises the following steps:

[0051] Step 1: Clean the aluminum nitride ceramic plate, soak it in absolute ethanol, then ultrasonically in acetone and absolute ethanol for 10-15 minutes, after drying, clean it with radio frequency plasma in the magnetron sputtering chamber for 20-20 minutes. 30min;

[0052] Step 2, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass in argon gas with a purity of 99.99%, the air flow is 30sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 150W for titanium with a purity of 99.99% Plasma cleaning is performed on the surface of the target for 25 minutes, and then the base negative bias is applied -100V, then the titanium target baffle is opened, and the sputtering deposition starts. layer preparation.

[0053] Step 3, the chamber pressure is still main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com