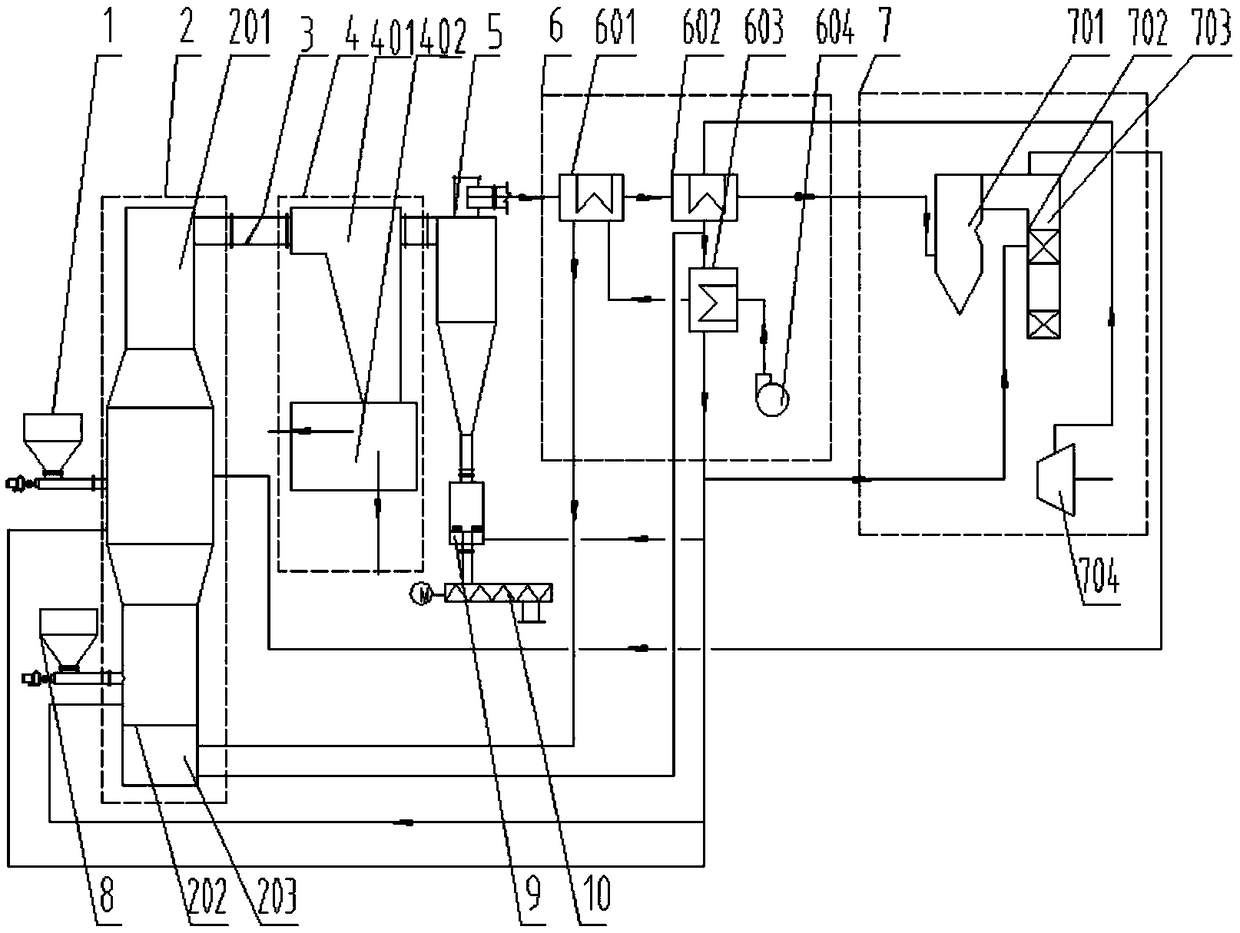

Device and method for power generation and carbon co-production by using biomass gasification coupling coal-fired unit

A technology of coal-fired units and biomass charcoal, which is applied in the direction of gasification process, granular/powdered fuel gasification, and production of combustible gas. value, high-efficiency power generation, and the effect of increasing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The biomass coupling power generation power is 30MW, and the power supply coal consumption of power station unit 7 last year was 305g / kW.h. The biomass raw material used is corn straw with a moisture content of 35%, and the impurity content is 3%. The corn straw consumption per hour is 36.65t / h .

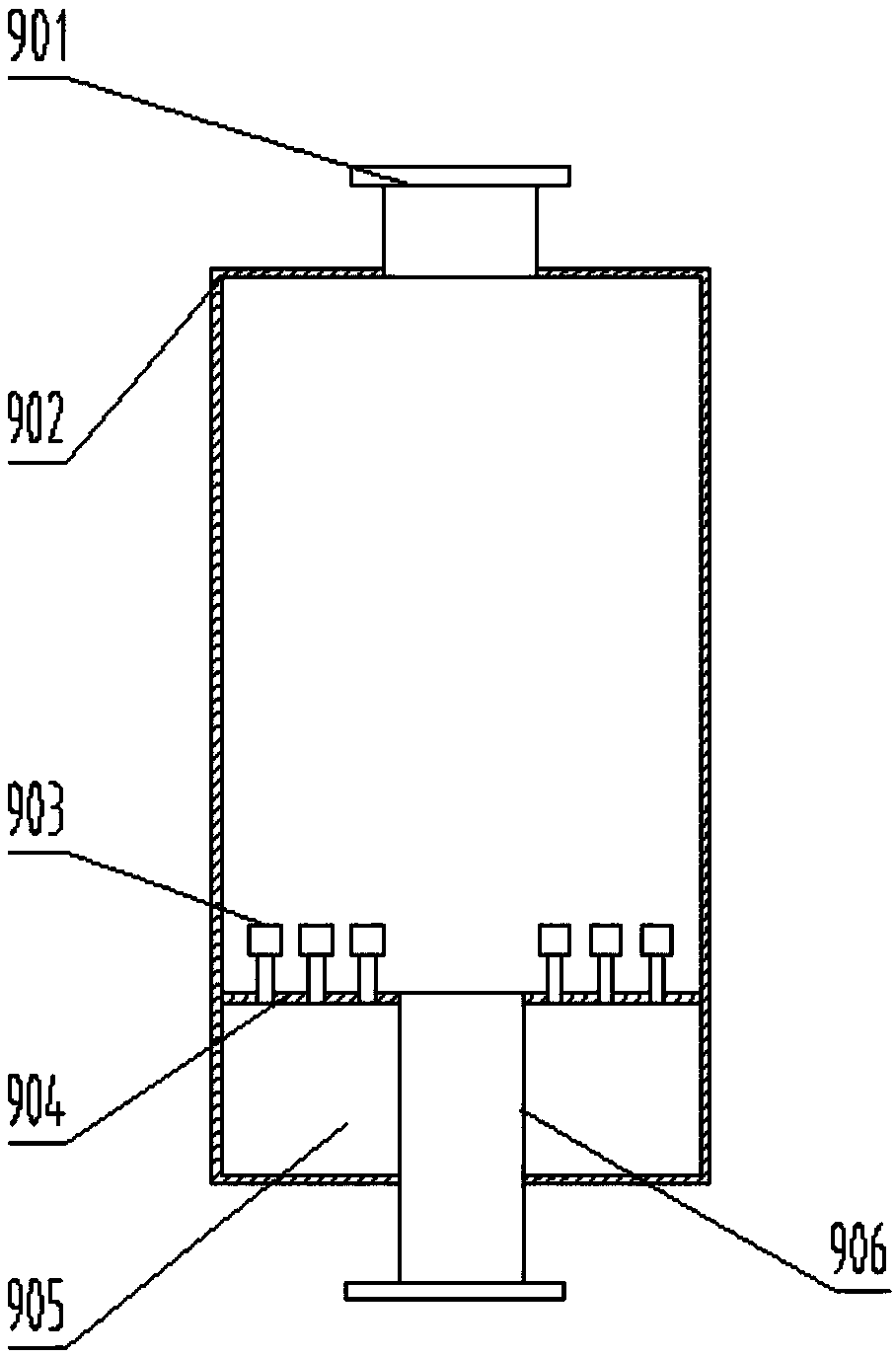

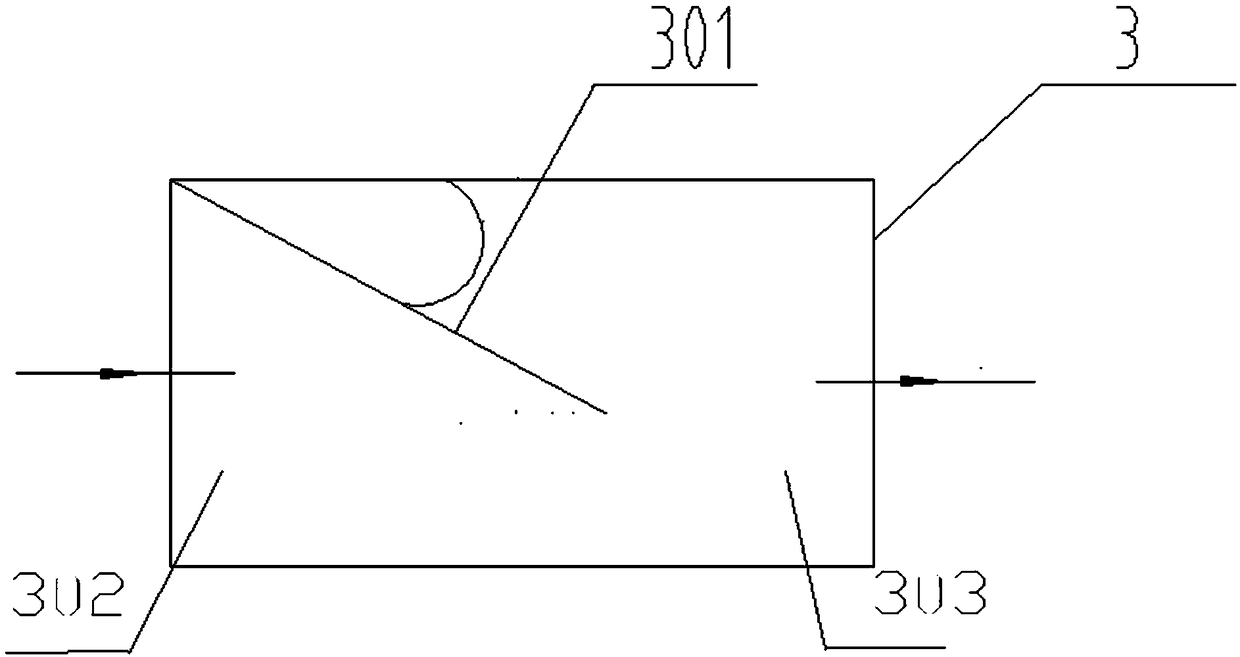

[0053] Under the auxiliary fluidization of the bed material in the furnace 201, corn stalks undergo gasification reaction to generate high-temperature biomass gas and biomass charcoal. The air volume required for gasification is 31500Nm 3 / h, the air temperature is 400°C, 1.3t / h of steam with a temperature of 600°C enters from the air chamber 203, and 1.1t / h of steam with a temperature of 230°C is injected from the speed-regulating steam inlet, and the high-temperature biomass gas carries biomass The charcoal enters the inertial separator 401 after passing through the efficiency adjustment device 3 for gas-solid separation. Under the centrifugal force, the large-particle biom...

Embodiment 2

[0058] The biomass coupled power generation power is 40MW, and the power supply coal consumption of power station unit 4 last year was 275g / kW.h. The biomass raw material used is wood chips with a moisture content of 15%, and the impurity content is 1.2%. The wood chips consumed per hour are 33.07t / h.

[0059] Sawdust undergoes gasification reaction under the auxiliary fluidization of the bed material in the furnace 201 to generate high-temperature biomass gas and biomass charcoal, and the air volume required for gasification is 26300Nm 3 / h, the air temperature is 300°C, 2.7t / h of steam with a temperature of 400°C enters from the air chamber 203, and 2.1t / h of steam with a temperature of 220°C is injected from the speed-regulating steam inlet, and the high-temperature biomass gas carries biomass The charcoal enters the inertial separator 401 after passing through the efficiency adjustment device 3 for gas-solid separation. Under the centrifugal force, the large-particle biomas...

Embodiment 3

[0064] The biomass coupling power generation power is 24MW, and the power supply coal consumption of the power station unit 7 in the previous year was 356g / kW.h. The biomass raw material used is rice husk with a moisture content of 13%, and the impurity content is 4.5%. The rice husk consumption is 34.23t / h per hour .

[0065] The rice husk undergoes a gasification reaction under the auxiliary fluidization of the bed material in the furnace 201 to generate high-temperature biomass gas and biomass charcoal, and the air volume required for gasification is 28300Nm 3 / h, the air temperature is 350°C, 2.1t / h of steam with a temperature of 500°C enters from the air chamber 203, and 1.7t / h of steam with a temperature of 260°C is injected from the speed-regulating steam inlet, and the high-temperature biomass gas carries biomass The charcoal enters the inertial separator 401 after passing through the efficiency adjustment device 3 for gas-solid separation. Under the centrifugal force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com