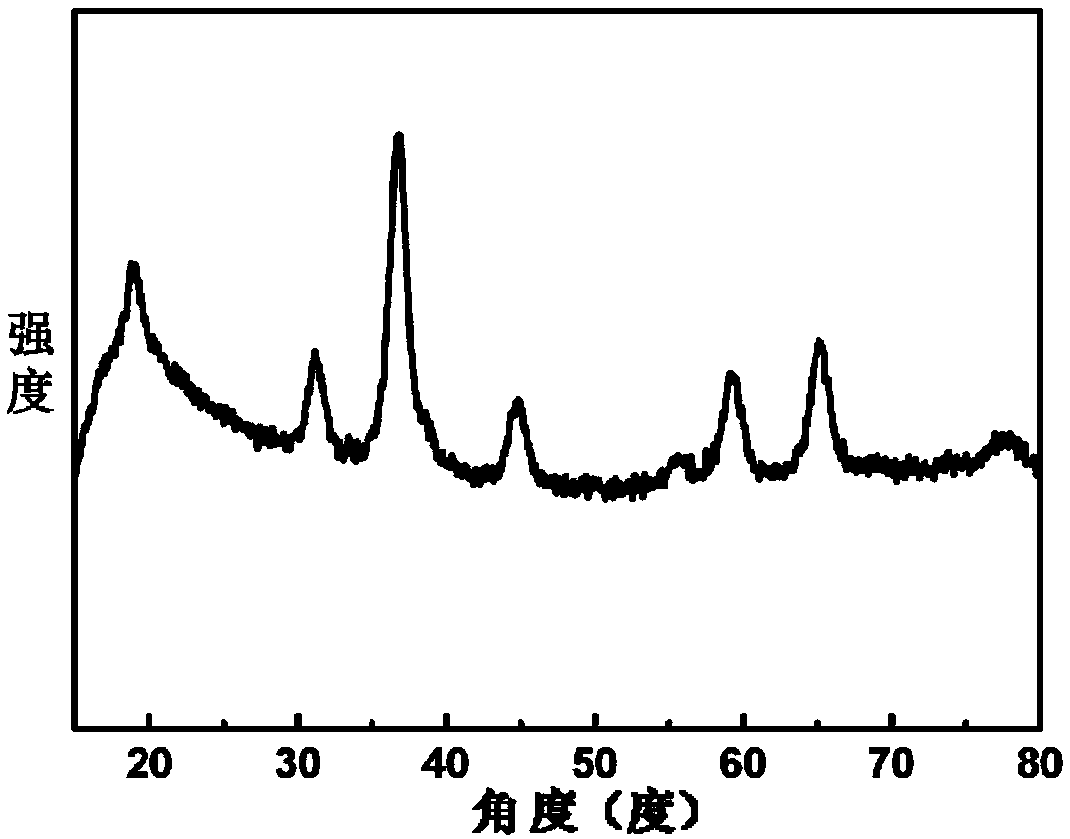

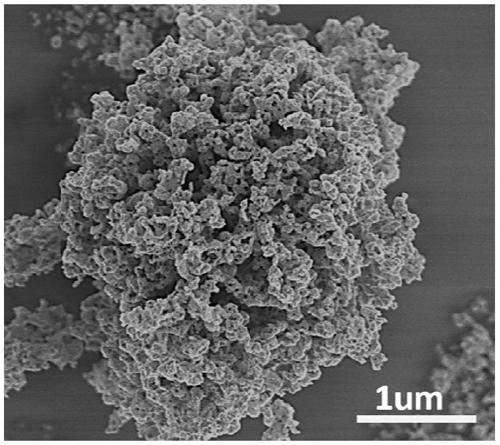

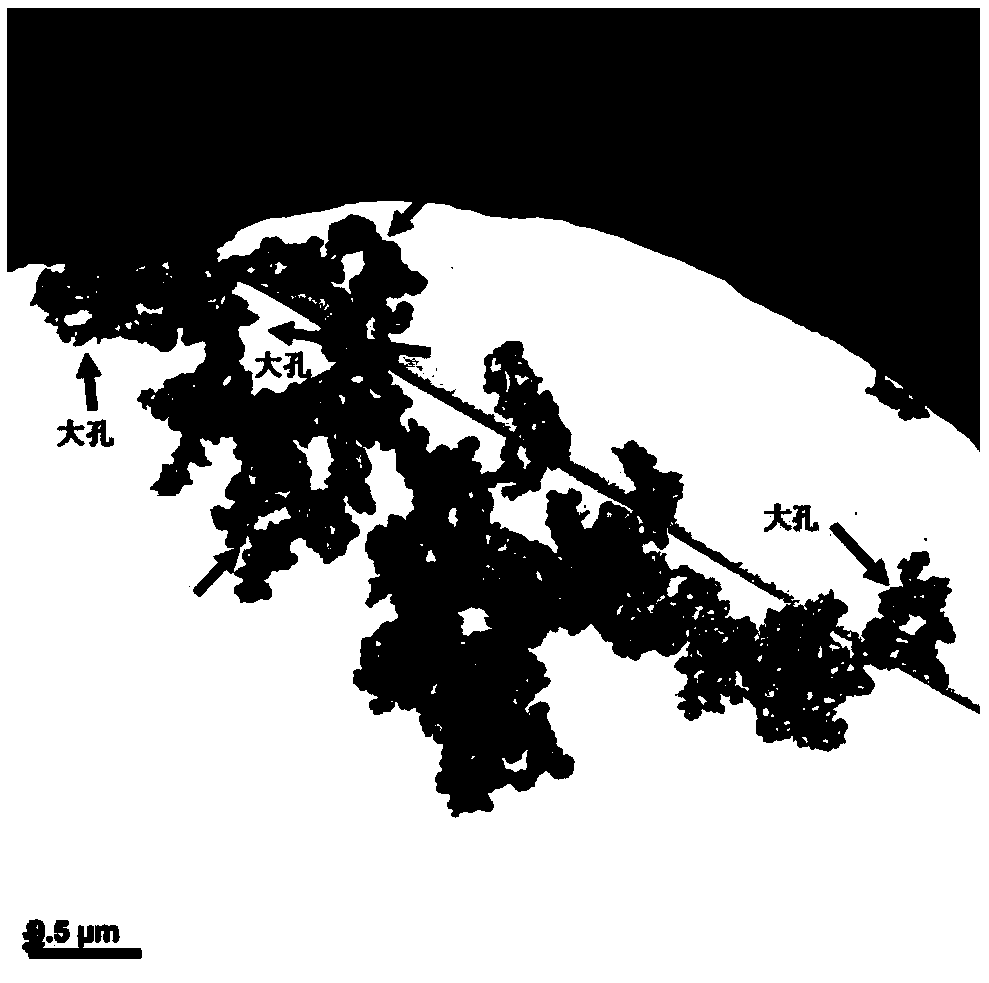

Method for preparing three-dimensional microporous structure spinel cobalt manganese binary oxide

A technology of binary oxides and three-dimensional macropores, applied in cobalt compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low yield and inconvenient mass production, and achieve high specific surface area, low environmental pollution, and solvent-free The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the spinel cobalt manganese binary oxide with three-dimensional macroporous structure prepared by the method of the present invention comprises the following steps:

[0020] (1) Slowly preheat the low-carbon alcohol solvent to 30~60 ℃, add the mixed acetate whose mass is 0.5%~2% of the solvent mass to the warm alcohol at one time, and stir vigorously until the cobalt acetate and manganese acetate are all Dissolve to obtain a pink solution, continue to stir vigorously at constant temperature for 3 to 6 hours, slowly cool down to room temperature, and age for 24 to 48 hours to obtain a suspension;

[0021] (2) Centrifuge the suspension of the above-mentioned step (1), wash the precursor three times with the same solvent as the above-mentioned step (1), remove the residual cobalt acetate and manganese acetate, and place it in an 80-degree oven to dry for 12-24 minutes hours, the pink organic salt precursor is obtained, and the solvent is recovered...

Embodiment 1

[0027] (1) Preparation of organic cobalt salt precursor: 100 g of ethanol was slowly preheated to 40° C., 1 g of mixed acetate (the mixture was Co(Ac) 2 ·4H 2 O and Mn(Ac) 2 ·4H 2 O, wherein the molar ratio of cobalt and manganese is 2:1) add it to the warm alcohol at one time, stir vigorously until the cobalt acetate and manganese acetate are all dissolved to obtain a pink solution. After continuous vigorous stirring at constant temperature for 3 hours, the temperature was slowly lowered to room temperature and aged for 36 hours. The suspension was centrifuged, and the precursor was washed three times with ethanol to remove residual cobalt acetate and manganese acetate, and dried in an oven at 80 degrees for 24 hours to obtain a pink organic salt precursor. The solvent can be recycled and reused;

[0028] (2) The precursor is ground finely and passed through a 300-mesh sieve. At a heating rate of 0.5 °C / min, the temperature was raised to 270 °C in the air, calcined for 9...

Embodiment 2

[0030] (1) Preparation of organic cobalt salt precursor: 100 g of ethanol was slowly preheated to 40° C., 1 g of mixed acetate (the mixture was Co(Ac) 2 ·4H 2 O and Mn(Ac) 2 ·4H 2 (O, wherein the molar ratio of cobalt and manganese is 3:1) is added to the warm alcohol at one time, and vigorously stirred until the cobalt acetate and manganese acetate are all dissolved to obtain a pink solution. After continuous vigorous stirring at constant temperature for 3 hours, the temperature was slowly lowered to room temperature and aged for 26 hours. The suspension was centrifuged, and the precursor was washed three times with ethanol to remove residual cobalt acetate and manganese acetate, and dried in an oven at 80 degrees for 24 hours to obtain a pink organic salt precursor. The solvent can be recycled and reused;

[0031] (2) The precursor is ground finely and passed through a 300-mesh sieve. At a heating rate of 0.5°C / min, the temperature was raised to 270°C in the air, calcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com