Preparation method and application of molecularly imprinted polymer-ferric oxide electrochemiluminescence sensor

A technology of ferroferric oxide and electrochemistry, which is applied in the direction of chemiluminescence/bioluminescence, electrochemical variables of materials, and analysis through chemical reactions of materials, etc. The preparation method and application of electrochemiluminescent sensors to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] The preparation method of the electrochemiluminescent sensor based on molecularly imprinted polymer-ferric oxide, the specific steps are as follows:

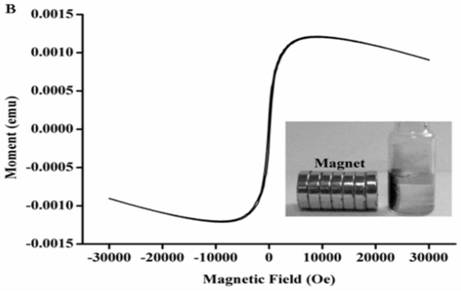

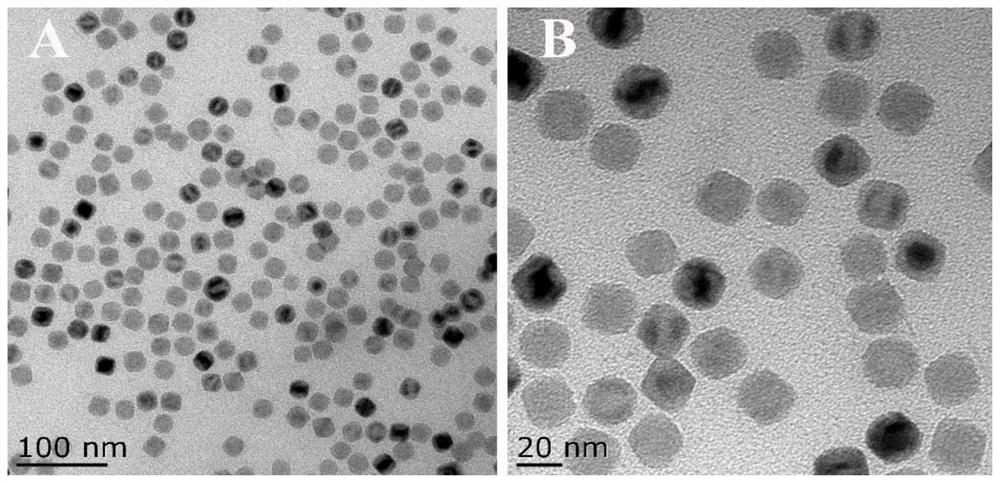

[0037] (1) Fe 3 o 4 nanocrystals (Fe 3 o 4 -NCs) preparation

[0038] A. Preparation of iron oleate precursor solution: weigh 2.53g of FeCl 3 ·6H 2 O was dissolved in 25mL of secondary water; 8.86mL of oleic acid was dissolved in 32mL of ethanol; the above two solutions were mixed and added to a three-necked flask, stirred at 70°C for 4 hours, the solution was divided into two layers, and the oil containing The upper layer of the acid-iron complex is washed 3 times in a separatory funnel with deionized water, and then the n-hexane is removed under vacuum conditions to obtain a waxy solid which is the iron-oleate complex;

[0039] B. Dissolve 1mL of iron oleate complex, 3mL of n-trioctylamine (TOA) in 8mL of octadecene (ODE), put the mixture in a three-necked flask, vacuumize at 100°C for 1 hour, and then in Under...

specific Embodiment 2

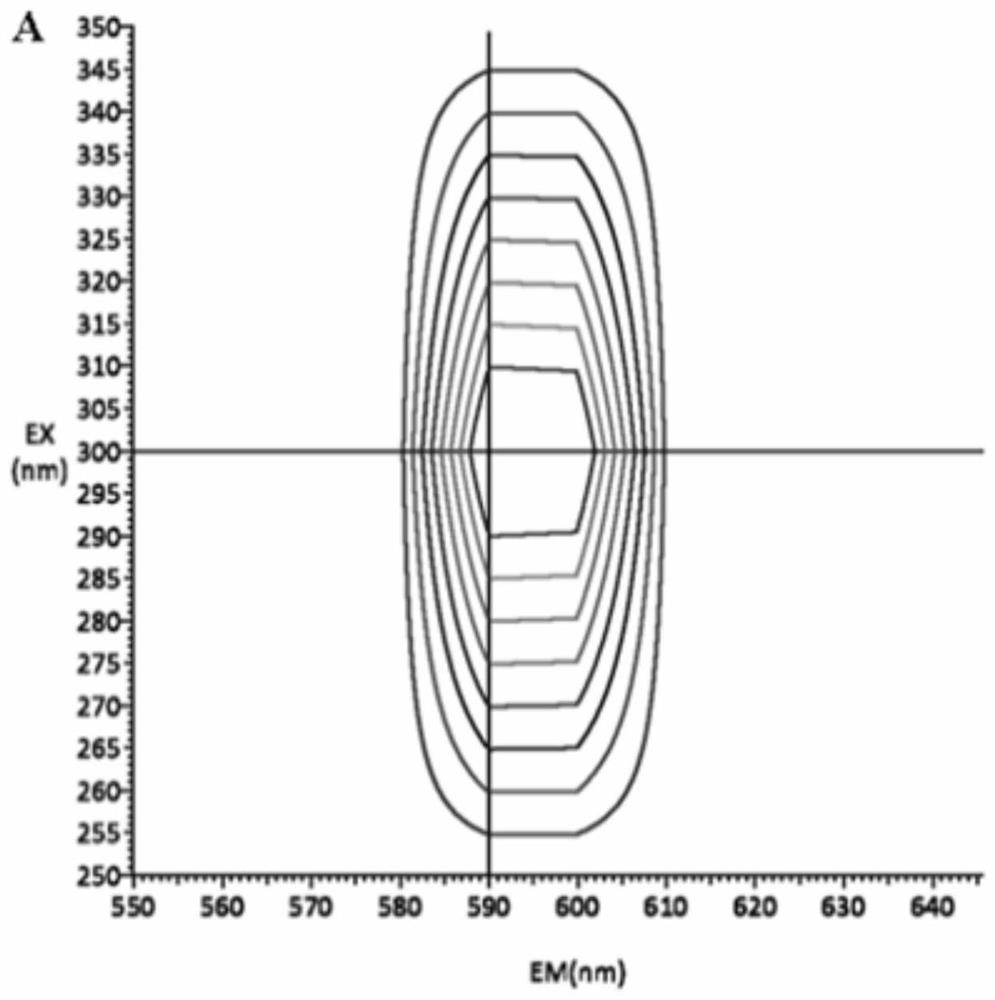

[0052] Condition optimization of molecular imprinting-electrochemiluminescence detection system, in which luminol concentration, polymer concentration, PBS buffer concentration and system pH value have important influence on electrochemiluminescence signal intensity and system sensitivity, selectivity and stability .

[0053] 1. Effect of luminol concentration on the intensity of electrochemiluminescence

[0054] As a luminescent precursor substance, the concentration of luminol is crucial to whether the system can produce continuous and stable optical signals. Therefore, the experiment first investigated the influence of the concentration of 0.2-1.0mM luminol on the intensity of electrochemiluminescence of the system. From Figure 8 It can be seen that as the concentration of luminol increases, the value of the electrochemiluminescence signal increases continuously. When the luminol concentration increased to 0.6mM, the relative luminous intensity of the system was the lar...

specific Embodiment 3

[0062] The method for detecting the concentration of bisphenol A using the electrochemiluminescence sensor for detecting bisphenol A prepared under the optimized conditions of the above specific embodiment 1 and specific embodiment 2, the specific steps are as follows:

[0063] The electrochemiluminescence test was carried out in a self-made Teflon electrolytic cell, the base was made of transparent quartz material, and the volume was 10.0mL. The electrochemiluminescence sensor based on molecularly imprinted polymer-ferric oxide is used as the working electrode, the platinum wire electrode is used as the auxiliary electrode (counter electrode), and Ag / AgCl (KCl saturated solution saturated with AgCl) is used as the reference electrode, using MPI -E-type electrochemiluminescence system for electrochemiluminescence analysis; system conditions: PBS buffer concentration is 60mM, pH is 10.0, luminol concentration is 0.6mM; instrument conditions: photomultiplier tube negative high vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com