Preparation method of Ni (OH) 2/multilayer graphene composite material

A technology of multi-layer graphene and composite materials, applied in the field of materials, can solve problems such as poor electrical conductivity, poor rate performance and cycle performance, and large internal resistance of electrodes, and achieve the effects of easy control, simple process, and improved redox activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

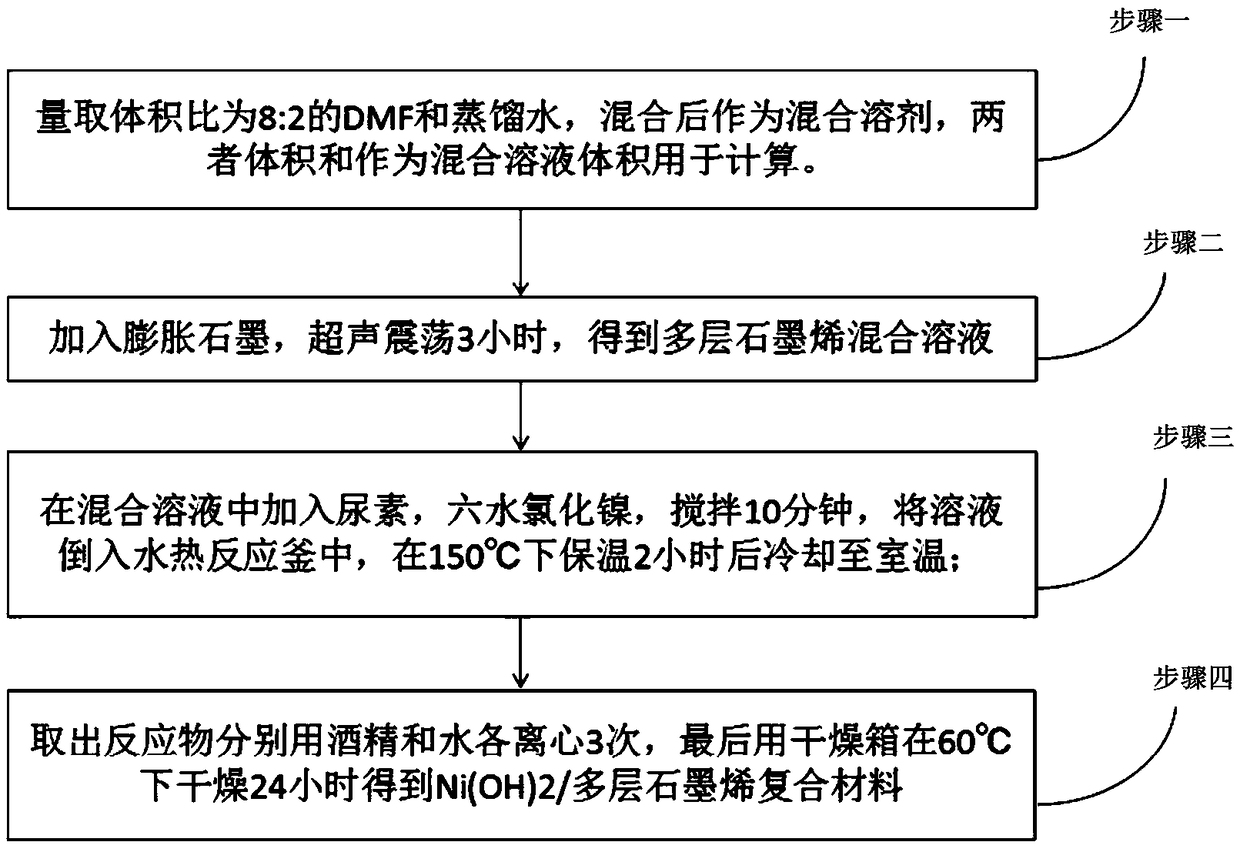

[0025] figure 1 Be the Ni(OH) of the embodiment of the present invention 2 The preparation method step flowchart of / multilayer graphene composite material comprises the following steps:

[0026] Step 1, measure DMF (N,N-dimethylformamide) and distilled water with a volume ratio of 8:2, and mix them as a mixed solvent. The volume of the two solvents and the volume of the mixed solvent.

[0027] Step 2, add expanded graphite, and ultrasonically vibrate for 3 hours to obtain a mixed solution of multilayer graphene; wherein, the mass concentration of expanded graphite relative to the mixed solvent is 2 mg / mL, and the oxygen content on the surface of the multilayer graphene is less than 3%, and the number of layers Less than 100 layers.

[0028] Step 3: Add urea and nickel chloride hexahydrate into the multilayer graphene mixed solvent, stir for 5-10 minutes, pour the solution into a hydrothermal reaction kettle, keep it at 150°C for 2 hours, and then cool to room temperature. ...

Embodiment 1

[0031] Mix 8mLDMF and 2mL distilled water as a mixed solvent, add 20mg of expanded graphite, and obtain the required multilayer graphene solution after ultrasonic oscillation for 3 hours, add 30mg CO(NH2) to the mixed solution 2 , 95.2mg NiCl 2 ·6H 2 O and stirred for 10 minutes; pour the solution into a hydrothermal reaction kettle, keep it warm at 150°C for 2 hours, and then cool to room temperature; take out the product and wash it with alcohol for 3 times, and then wash it with water for 3 times, and finally use a drying oven at 60°C Drying for 24 hours to obtain Ni(OH) 2 / Multilayer graphene composites.

Embodiment 2

[0033] Mix 8mLDMF and 2mL distilled water as a mixed solvent, add 20mg expanded graphite, and obtain the required multilayer graphene solution after ultrasonic oscillation for 3 hours, add 40mg CO(NH2) to the mixed solution 2 , 119mg NiCl 2 ·6H 2 O and stirred for 5 minutes; pour the solution into a hydrothermal reaction kettle, keep it warm at 150°C for 2 hours, and then cool to room temperature; take out the product and wash it with alcohol for 3 times, and then wash it with water for 3 times, and finally use a drying oven at 60°C Drying for 24 hours to obtain Ni(OH) 2 / Multilayer graphene composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com