Large-size silver-loaded hydroxyapatite porous microsphere material and preparation method thereof

A porous microsphere, large-scale technology, applied in chemical instruments and methods, phosphorus compounds, pharmaceutical formulations, etc., can solve problems such as lack of antibacterial activity, and achieve the effect of avoiding secondary treatment, good sphericity, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

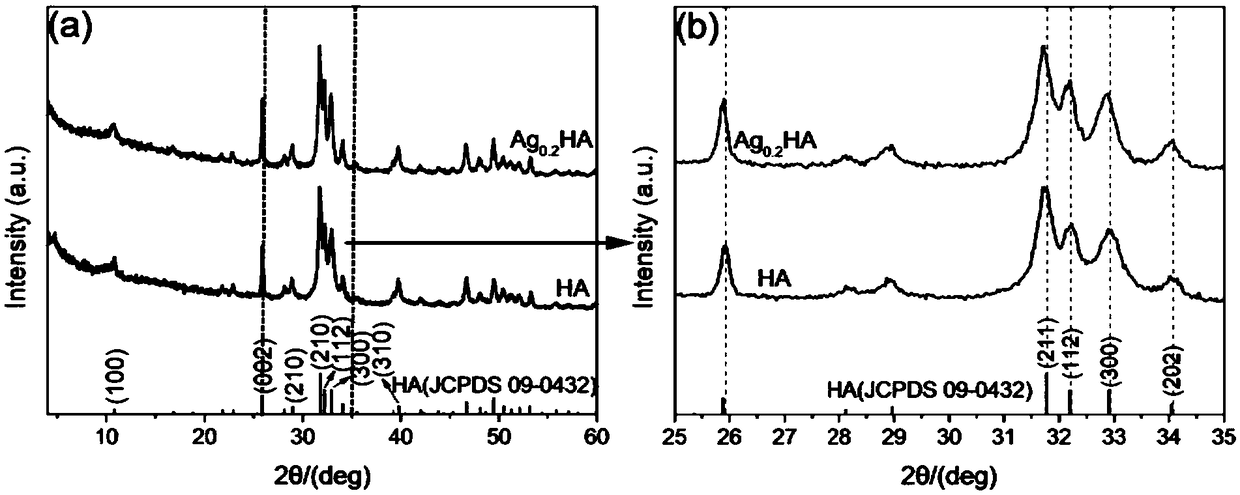

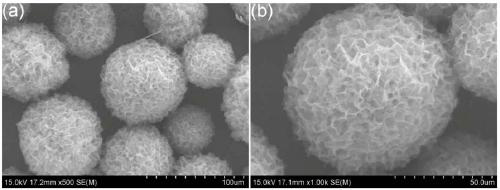

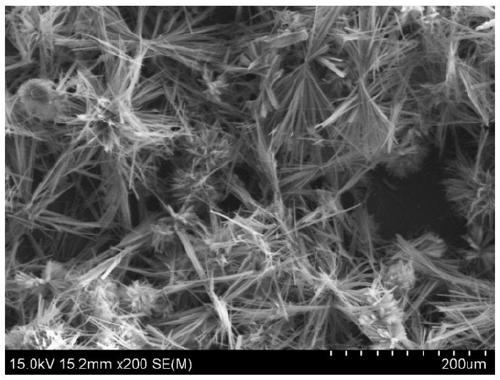

[0051] The synthetic reaction raw material of a kind of large-scale Ag-HA porous microsphere material mainly comprises several reagents of following amount: n[Ca(NO 3 ) 2 4H 2 O]:n[(NH 4 ) 2 HPO 4 ]: n[L-glutamic acid]=10.8:6:15, urea 1mol / L, AgNO 3 The powder is added according to the atomic ratio Ag / [Ag+Ca]=2%, HNO 3 : 0.05mol / L, the solvent is deionized water.

[0052] The preparation method of above-mentioned precursor solution is as follows: first Ca(NO 3 ) 2 4H 2 O, (NH 4 ) 2 HPO 4 , three solutions of urea were mixed in a beaker, stirred evenly by magnetic force and then added dilute HNO 3 Adjust the pH of the solution; then add L-glutamic acid to the solution and stir well, then add AgNO 3 Stir the powder, and finally pour the above mixture into a polytetrafluoroethylene-lined kettle, place it in a blast drying oven, and set the reaction temperature and reaction time to 160°C and 6h, respectively. After the reaction was completed, the reaction vessel was ...

Embodiment 2

[0055] The synthetic reaction raw material of a kind of large-scale Ag-HA porous microsphere material mainly comprises several reagents of following amount: n[Ca(NO 3 ) 2 4H 2 O]:n[(NH 4 ) 2 HPO 4 ]: n[L-glutamic acid]=10.8:6:15, urea 1mol / L, AgNO 3 The powder is added according to the atomic ratio Ag / [Ag+Ca]=4%, HNO 3 : 0.05mol / L, the solvent is deionized water.

[0056] The preparation method of above-mentioned precursor solution is as follows: first Ca(NO 3 ) 2 4H 2 O, (NH 4 ) 2 HPO 4 , three solutions of urea were mixed in a beaker, stirred evenly by magnetic force and then added dilute HNO 3 Adjust the pH of the solution; then add L-glutamic acid to the solution and stir well, then add AgNO 3 Stir the powder, and finally pour the above mixture into a polytetrafluoroethylene-lined kettle, place it in a blast drying oven, and set the reaction temperature and reaction time to 160°C and 6h, respectively. After the reaction was completed, the reaction vessel was ...

Embodiment 3

[0058] The synthetic reaction raw material of a kind of large-scale Ag-HA porous microsphere material mainly comprises several reagents of following amount: n[Ca(NO 3 ) 2 4H 2 O]:n[(NH 4 ) 2 HPO 4 ]: n[L-glutamic acid]=10.8:6:15, urea 1mol / L, AgNO 3 The powder is added according to the atomic ratio Ag / [Ag+Ca]=6%, HNO 3 : 0.05mol / L, the solvent is deionized water.

[0059] The preparation method of above-mentioned precursor solution is as follows: first Ca(NO 3 ) 2 4H 2 O, (NH 4 ) 2 HPO 4 , three solutions of urea were mixed in a beaker, stirred evenly by magnetic force and then added dilute HNO 3 Adjust the pH of the solution; then add L-glutamic acid to the solution and stir well, then add AgNO 3 Stir the powder, and finally pour the above mixture into a polytetrafluoroethylene-lined kettle, place it in a blast drying oven, and set the reaction temperature and reaction time to 160°C and 6h, respectively. After the reaction was completed, the reaction vessel was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com