Continuous carbon fiber recovering method and continuous carbon fiber recovering device

A technology for recycling carbon fibers and carbon fibers, applied in the field of continuous carbon fiber recycling devices, can solve the problems of difficult recycling of catalysts, waste of resources, recycling costs, and damage to the mechanical properties of carbon fibers, reducing heat transfer and reaction time, improving carbon fiber recovery rates, The effect of maintaining mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

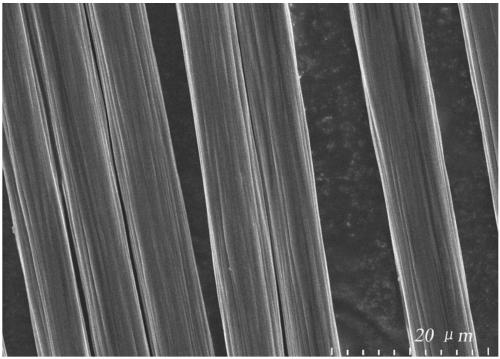

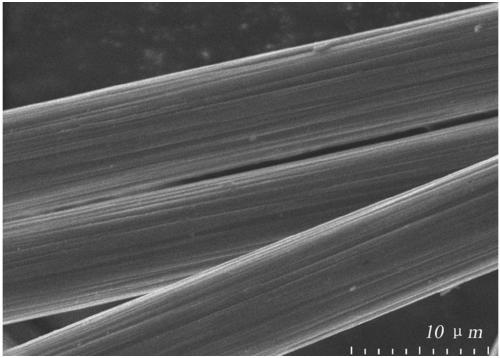

[0084] The selected waste carbon fiber-reinforced resin-based composite material is made of Japanese TORAY T300-3K twill weave and epoxy resin, and the carbon fiber content is 60%;

[0085] Weighing 500g of waste carbon fiber reinforced resin-based composite material pieces with a thickness of 3mm and not greater than 25×25mm, and putting them into the first feeding device 15;

[0086] SO with a particle size of 0.8mm 4 2- / ZrO 2 Solid superacid particles are placed in the second feeding device 17 .

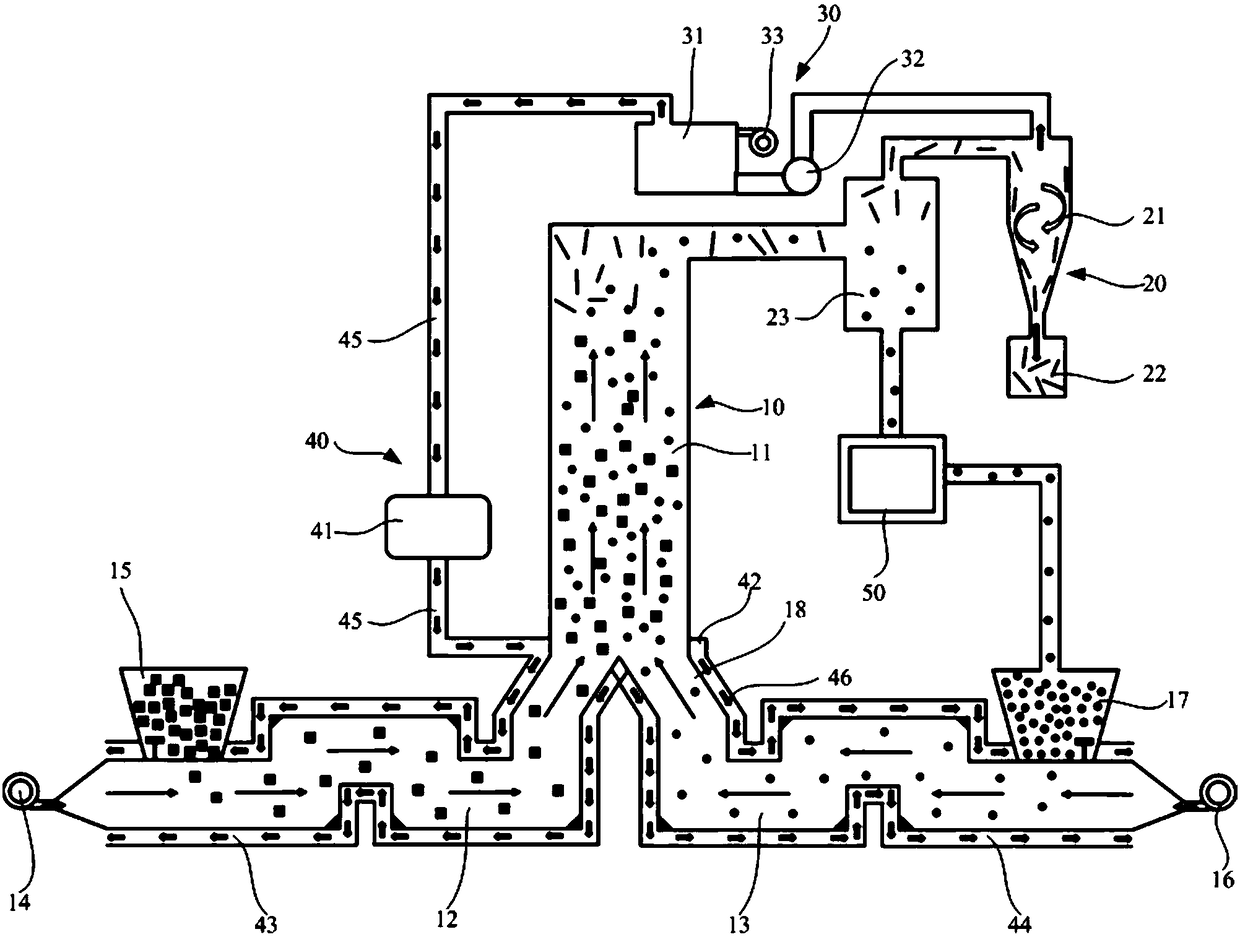

[0087] Step (1): Air is blown into the high-temperature burner 31 through the third blower 33, and the air heated to 1000°C is cooled to 450°C by the heat exchanger 41 and then enters the main interlayer 42, and then enters the first interlayer 43 and the In the second interlayer 44, the lower end of the thermal cracking furnace 11 is heated, and the first preheating pipe 12 and the second preheating pipe 13 are preheated simultaneously, and the first air blower 14 and the sec...

Embodiment 2

[0091] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is that the selected solid superacid particles are WO 3 / ZrO 2 .

Embodiment 3

[0093] The selected waste carbon fiber-reinforced resin-based composite material is made of Toray Corporation (TORAY) T600S-24K twill weave and polyester resin, and the carbon fiber content is 65%;

[0094] Weighing 500g of waste carbon fiber reinforced resin-based composite material pieces with a thickness of 3mm and not greater than 45×45mm, and putting them into the first feeding device 15;

[0095] MoO with a particle size of 2mm 3 / ZrO 2 Solid superacid particles are placed in the second feeding device 17 .

[0096] Step (1): Air is blown into the high-temperature burner 31 through the third blower 33, and the air heated to 1350°C is cooled to 350°C by the heat exchanger 41 and enters the main interlayer 423, and then enters the first interlayer 43 and the In the second interlayer 44, the lower end of the thermal cracking furnace 11 is heated, and the first blower 14 and the second blower 16 are opened simultaneously to preheat the air in the first preheating pipe 12 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com