Elastic and stretchable electrochromic device

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as the inability to realize electrochromic devices, limit the application range of products, and unfavorable large-area display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

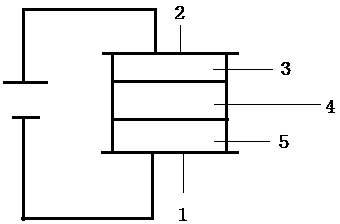

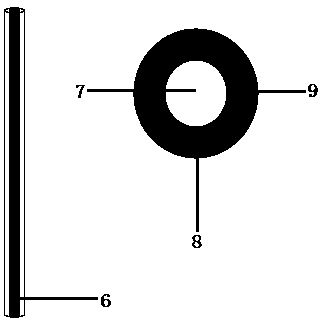

Image

Examples

Embodiment 1

[0026] Put the purchased lithium perchlorate and resin powder in 100 0 Dry in a vacuum oven for 24 hours.

[0027] Preparation of Elastic Electrochromic Film 1

[0028] Weigh 1.54g of lithium perchlorate and place it in a beaker, then measure 10ml of polycarbonate and add it into the beaker, stir and dissolve at room temperature, and store it in a vacuum drying oven after the dissolution is complete. Weigh 5.50g of the dried PVB resin powder and place it in a 500ml beaker, then add 1.25g of the prepared electrolyte solution, stir well and then add 0.3g of tungsten oxide, 0.85g of triethylene glycol diisocaprylate, and 0.25 g of methylsiloxane, 0.31 g of dibutylhydroxytoluene. After stirring evenly, add 40ml of dimethylformamide to dissolve, completely dissolve and store in an airtight seal.

[0029] Take 10g of electrochromic slurry and place it in the casting machine, set the temperature to 120 0 C, the speed is 3m / min, after curing at high temperature, an elastic electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com