Fe-doped MoS2 nanomaterial as well as preparation method and application thereof

A technology of nanomaterials and nickel foam, which is applied in the field of electrolytic water catalytic materials, can solve the problems of lengthy and complicated synthesis steps, and achieve the effects of simple operation, excellent catalytic performance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of iron-doped molybdenum disulfide nano-"umbrella"

[0038] Weigh 13mg (0.05mmol) of ammonium tetrathiomolybdate and 13.5mg (0.05mmol) of ferric chloride hexahydrate solid, dissolve in 12mL N,N-dimethylformamide (DMF) to form a solution, Then the solution was transferred into a stainless steel reaction kettle with polytetrafluoroethylene lining, sealed and placed in an oven, reacted at 200°C for 12h, and naturally cooled to room temperature after the reaction. After washing with deionized water and ethanol, centrifugation and drying, a black powdery iron-doped molybdenum disulfide nano-"canopy" was obtained, named Fe 0.05 -MoS 2 , where Fe represents iron ions, 0.05 represents that the molar amount of iron salt is 0.05mmol, and MoS 2 stands for molybdenum disulfide.

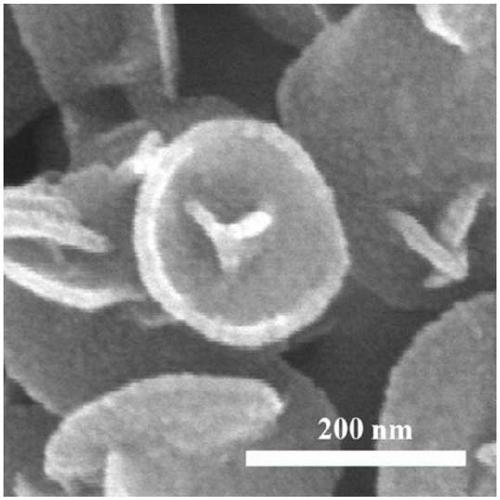

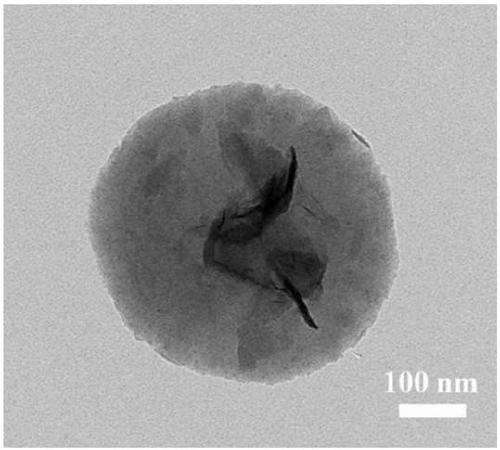

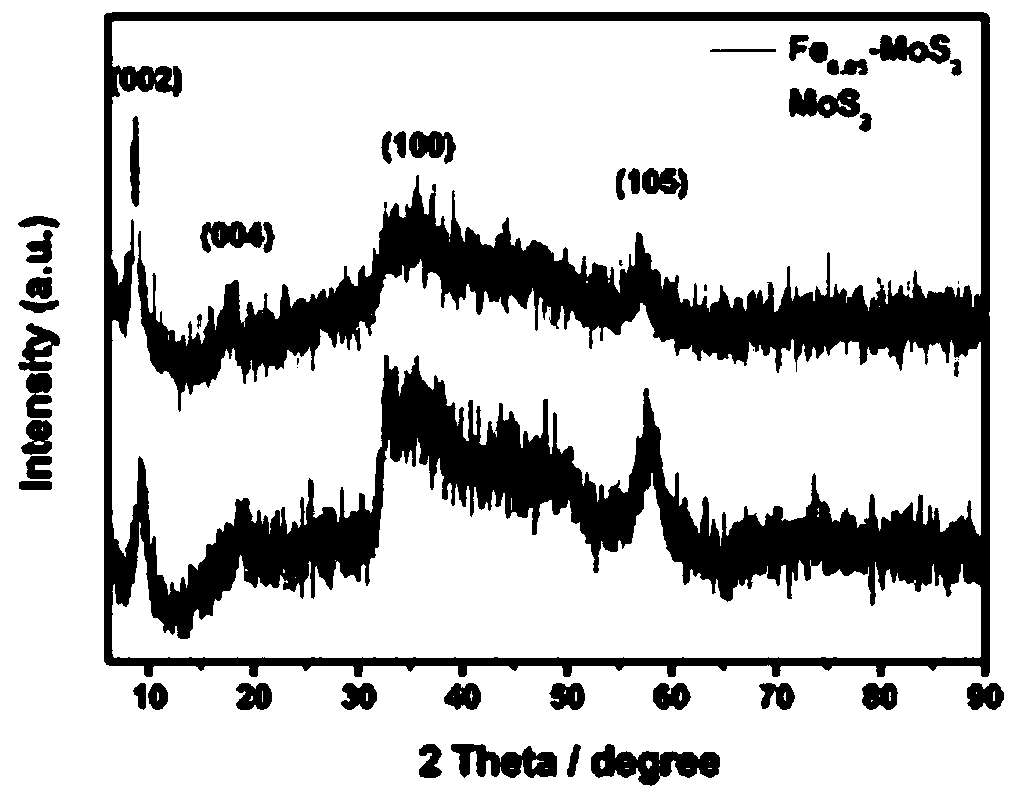

[0039] Such as figure 1 and figure 2 As shown, the nano-"umbrella" of iron-doped molybdenum disulfide has uniform morphology, high quality and high yield, its diameter is less th...

Embodiment 2

[0043] Example 2: Preparation of iron-doped molybdenum disulfide nano-"umbrella" electrocatalyst

[0044] Weigh 2.5mg of iron-doped molybdenum disulfide nano-"canopy" solid powder and 2.5mg of commercial carbon black for mixing, add 970 μL of isopropanol and 30 μL of 5wt.% Nafion solution, ultrasonic 1h to make it uniformly dispersed and form Ink-like solution. Take 20 μL of the above solution and add it dropwise to the surface of the polished glassy carbon electrode in batches, and let it dry naturally before use.

[0045] As a comparison, 2.5 mg of molybdenum disulfide solid powder and 2.5 mg of commercial carbon black were weighed and mixed, 970 μL of isopropanol and 30 μL of 5 wt.% Nafion solution were added, and ultrasonically dispersed for 1 h to form an ink-like solution. Take 20 μL of the above solution and add it dropwise to the surface of the polished glassy carbon electrode in batches, and let it dry naturally before use.

[0046] As a comparison, weigh 5.0 mg of ...

Embodiment 3

[0047] Example 3: HER performance test in acidic electrolyte

[0048] The entire electrocatalytic test is carried out under a standard three-electrode system, wherein the working electrode is the glassy carbon electrode prepared in Example 2, the reference electrode is an Ag / AgCl (saturated chlorine KCl solution) electrode, and the auxiliary electrode is a platinum wire electrode. The electrolyte solution used for the linear sweep voltammetry (LSV) test is 0.5M H 2 SO 4 Solution, the potential scanning range is -0.7 ~ 0V, the scanning speed is 5mV / s, and the test data have been compensated by iR.

[0049] Such as Figure 7 As shown, compared with pure MoS2, the iron-doped MoS2 nano-"canopy" exhibits excellent HER electrocatalytic performance at 10 mA cm -2 Under the current density, the value of overpotential is only 173mV, and the Tafel slope is also as low as 41.1mV·dec -1 . Double layer capacitance value is 39.8mF cm -2 , higher than that of molybdenum disulfide, indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com