Sewage treatment technology of chemical engineering plant

A sewage treatment and chemical plant technology, applied in the field of chemical plant sewage treatment process, can solve the problems of high treatment cost, unsatisfactory nitrogen and phosphorus removal effect, cumbersome process, etc., to improve removal efficiency, simplify sewage treatment steps, and increase resources The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

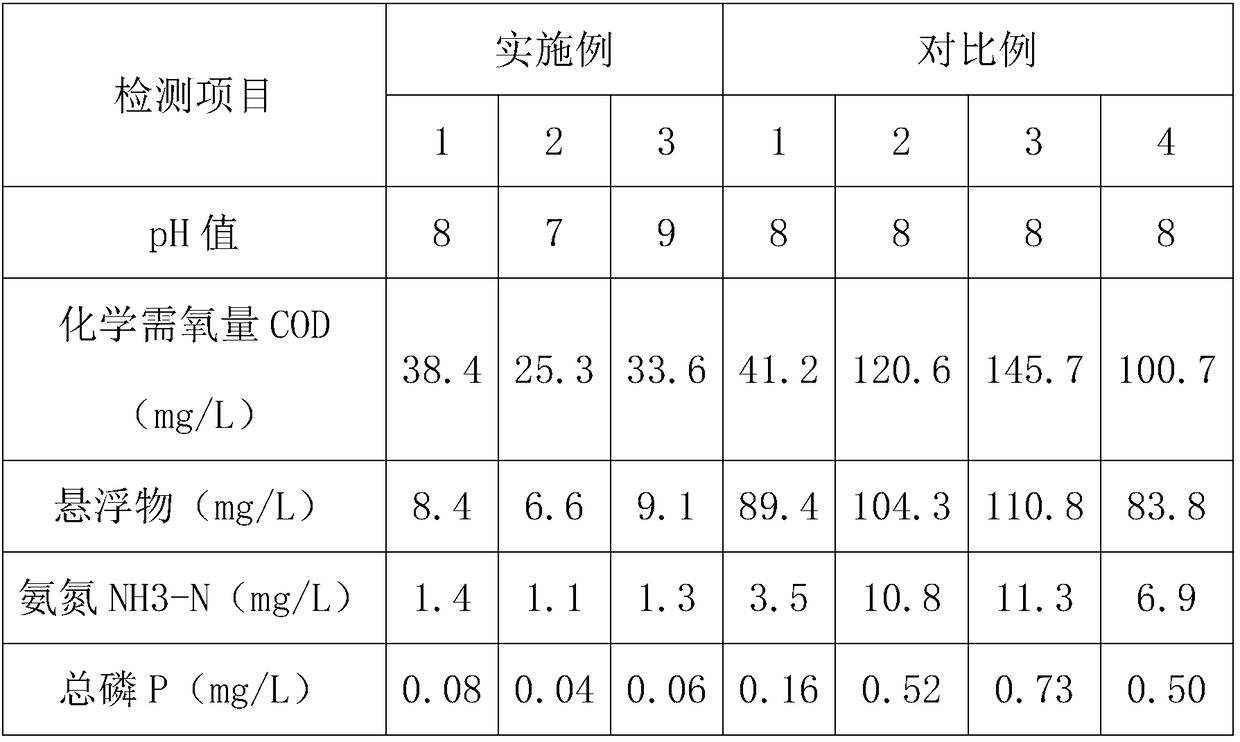

Embodiment 1

[0021] A kind of chemical plant sewage treatment process that the present invention proposes comprises the following steps:

[0022] S1. Initial adjustment of the pH value of sewage: the sewage is stored in the sewage collection tank, and then transported from the sewage collection tank to the initial pH value adjustment tank, and then the pH value is adjusted in the initial pH value adjustment tank by sulfuric acid solution with a mass concentration of 20%. 5.5, the treatment time of sewage in the initial pH adjustment tank is 5 minutes;

[0023] S2. Primary sedimentation of sewage: The sewage treated by the primary pH adjustment tank is introduced into the primary sedimentation tank, and 3PPM polyferric sulfate and 10PPM polystyrene divinyl styrene resin microspheres are put into the primary sedimentation tank, and the water is mixed with 100r Stir for 20 minutes at a speed of 1 / min, then settle, transfer the settled clear water to the nitrogen and phosphorus removal tank, a...

Embodiment 2

[0029] A kind of chemical plant sewage treatment process that the present invention proposes comprises the following steps:

[0030] S1. Initial adjustment of the pH value of sewage: the sewage is stored in the sewage collection tank, and then transported to the initial pH value adjustment tank by the sewage collection tank, and then the pH value is adjusted in the initial pH value adjustment tank by a sulfuric acid solution with a mass concentration of 15%. 6. The treatment time of sewage in the initial pH adjustment tank is 7 minutes;

[0031] S2. Primary sedimentation of sewage: The sewage treated by the pH adjustment tank is introduced into the primary sedimentation tank, and 5PPM polyferric sulfate and 12PPM polystyrene divinyl styrene resin microspheres are put into the primary sedimentation tank, and the water is charged at 150r Stir for 30 minutes at a speed of 1 / min, then settle, transfer the settled clear water to the nitrogen and phosphorus removal tank, and dischar...

Embodiment 3

[0037] A kind of chemical plant sewage treatment process that the present invention proposes comprises the following steps:

[0038] S1. Initial adjustment of the pH value of sewage: the sewage is stored in the sewage collection tank, and then transported to the initial pH value adjustment tank by the sewage collection tank, and then the pH value is adjusted in the pH value initial adjustment tank by a sulfuric acid solution with a mass concentration of 10%. 6.5, the treatment time of sewage in the initial pH adjustment tank is 8 minutes;

[0039] S2. Primary sedimentation of sewage: The sewage treated by the primary pH adjustment tank is introduced into the primary sedimentation tank, and 6PPM polyferric sulfate and 15PPM polystyrene divinylbenzene resin microspheres are put into the primary sedimentation tank, and the water is mixed with 200r Stir for 40 minutes at a speed of 1 / min, then settle, transfer the settled clear water to the nitrogen and phosphorus removal tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com