Zero-emission system for treating landfill leachate

A landfill leachate, zero-discharge technology, used in sedimentation treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that the salt cannot meet the industrial water reuse standard, the system design cost is increased, and the purified water is recycled. In order to improve the overall recovery rate, achieve sludge retention, and improve treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

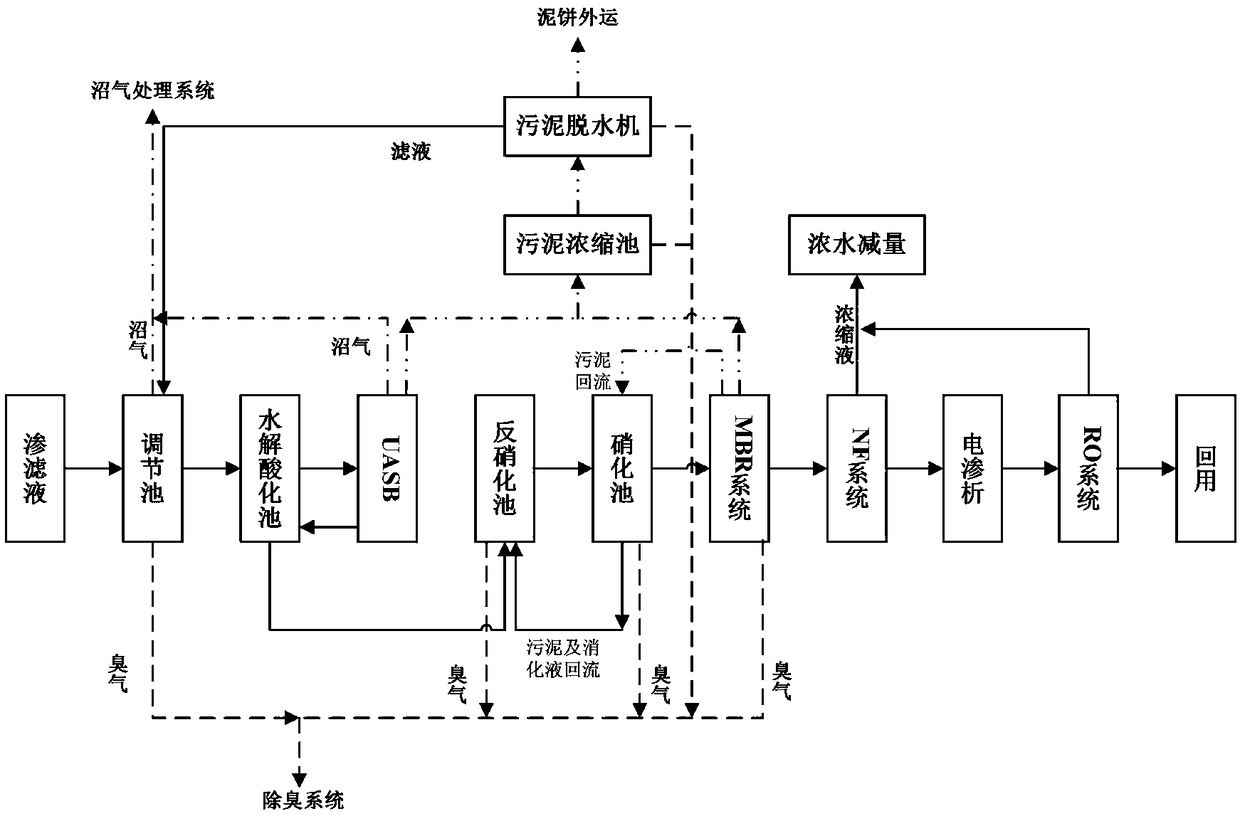

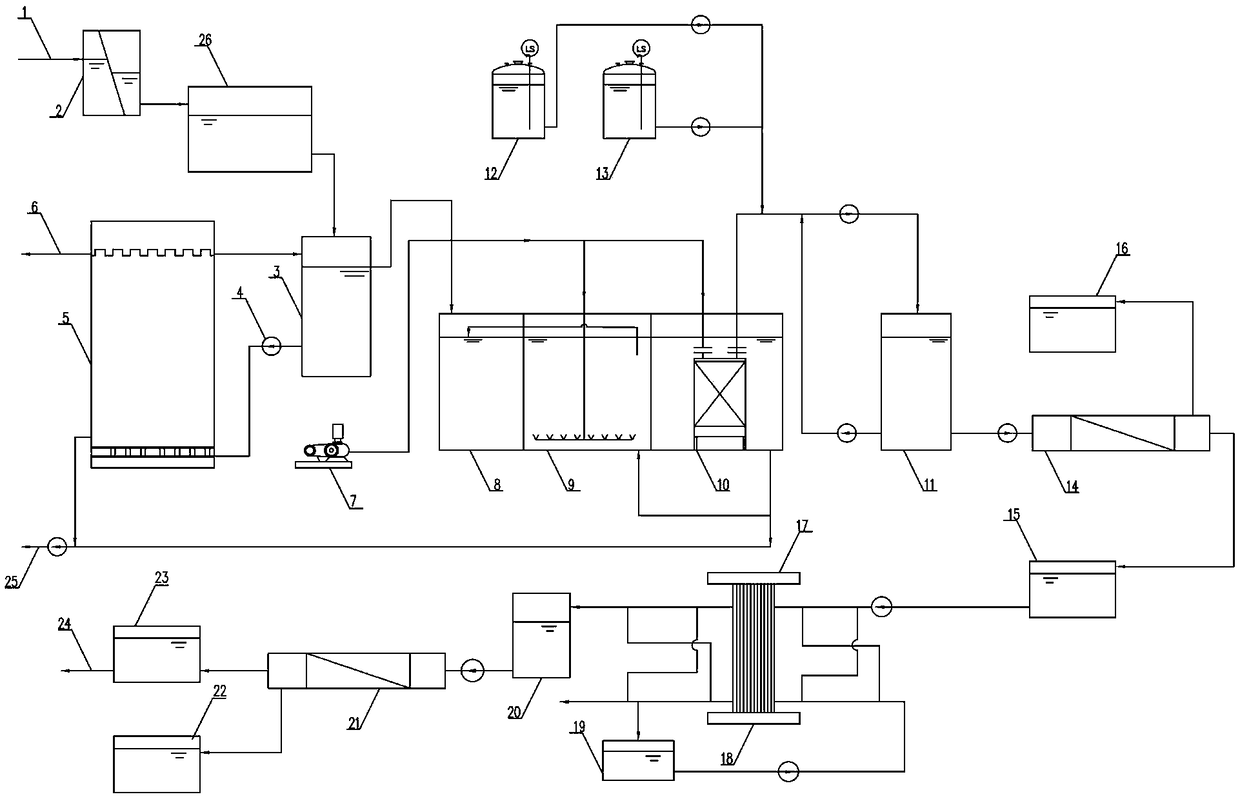

[0024] figure 1 , figure 2 As shown, it involves a zero-discharge system for landfill leachate treatment, including primary sedimentation tank 2, regulating tank 26, hydrolysis acidification tank 3, UASB reactor 5, A / O-MBR system, MBR membrane water production tank 11, Nanofiltration device 14, nanofiltration fresh water production water tank 15, electrodialysis system 17, electrodialysis fresh water tank 20 and RO reverse osmosis device 21, the output end of described RO reverse osmosis device 21 is connected with reverse osmosis concentrated water tank 22 and reverse osmosis fresh water respectively Box 23 is connected.

[0025] The high-efficiency anaerobic reactor 5 is an upflow anaerobic sludge bed reactor. The A / O-MBR system includes a denitrification tank 8, a nitrification tank 9, and an MBR membrane tank 10, and both the nitrification tank 9 and the MBR membrane tank 10 are equipped with a blast aeration device 7. The nitrification liquid in the nitrification tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com