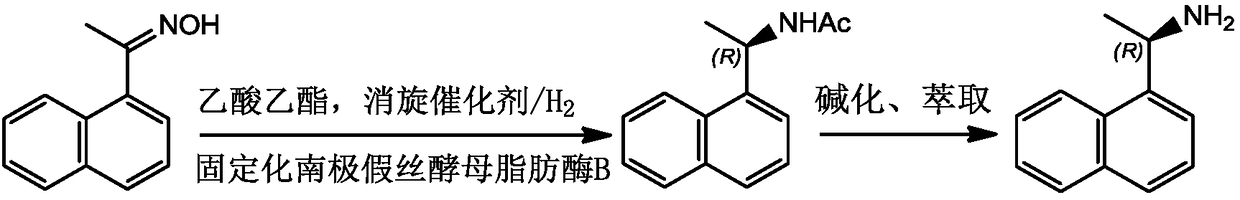

Enzymatic resolution method for preparation of (R)-1-(1-naphthyl) ethylamine

A technology of enzymatic separation and naphthyl, which is applied in the field of chemical enzymatic preparation of -1-ethylamine, can solve the problems of slow reaction speed of enzymatic method and easy falling off of palladium catalyst, and achieve high reusability and separation effect Excellent, good high temperature performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] The method for preparing (R)-1-(1-naphthyl)ethylamine by chemical enzymatic dynamic kinetic resolution of the present embodiment has the following steps:

[0035] (1) Preparation of immobilized CALB: prepare 20ml of Candida antarctica lipase B enzyme solution with a concentration of 1.0mg / mL, hereinafter referred to as CALB, add 150mg of epoxy resin to the enzyme solution, stir at 25°C for 3h, and then The oxygen resin is separated from the enzyme solution, washed with a pH=7.0 buffer solution, and dried in vacuum to obtain immobilized CALB, and the weight percentage of the enzyme protein in the immobilized enzyme is 3.0%;

[0036] (2) Reaction system A: In 5 mL of toluene solvent, add 250 mg of immobilized CALB prepared in step (1), 2565 mg of 1-(1-naphthyl) ethylamine racemate, and 264 mg of ethyl ethoxyacetate Esters were reacted at a constant temperature of 50°C for 9 hours. After the reaction, the solid and liquid were separated, the immobilized CALB was left in th...

example 2~ example 5

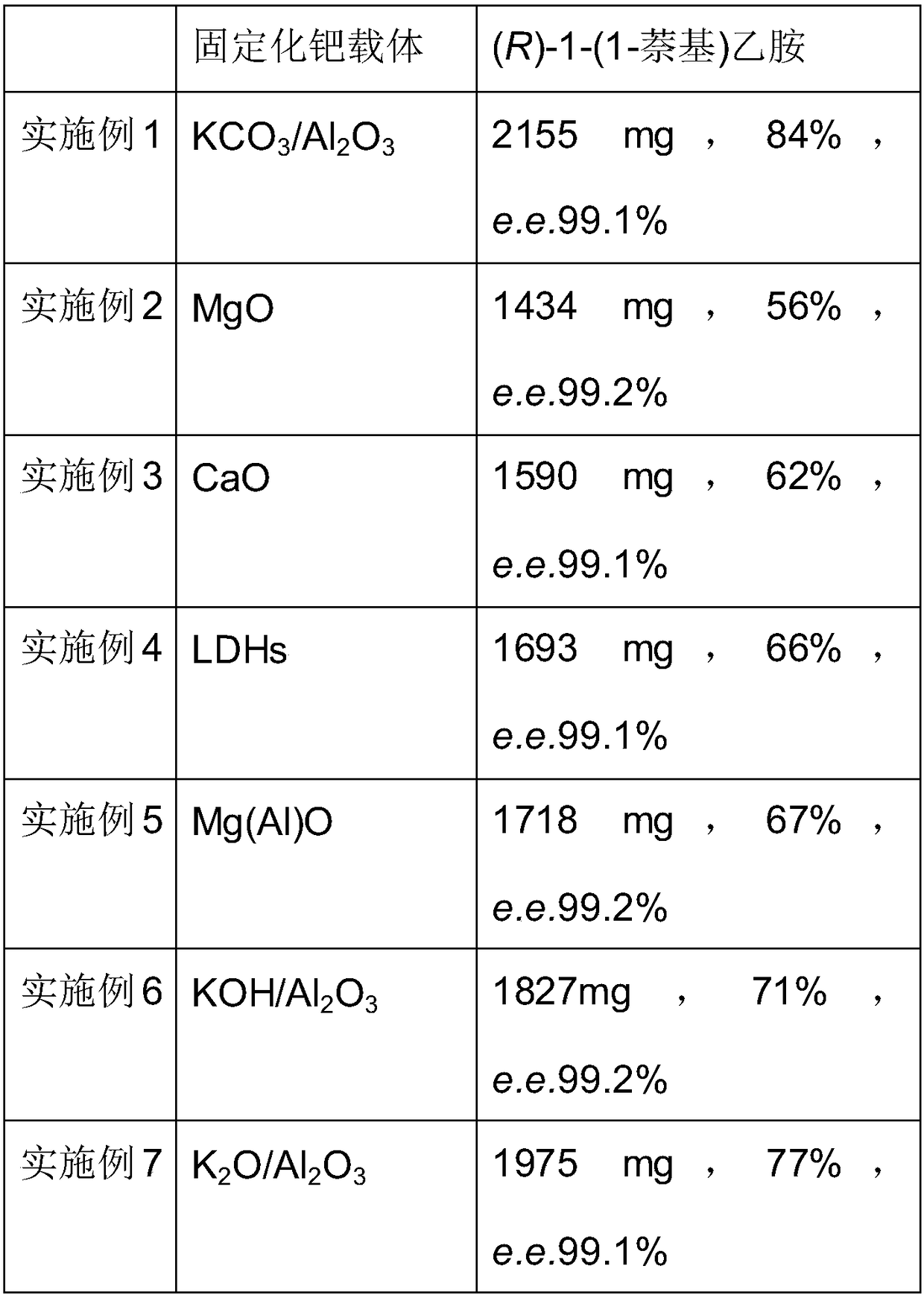

[0041] The method of each example is basically the same as Example 1, and the differences are shown in Table 1.

[0042] Table 1

[0043]

[0044] It can be seen from Table 1 that under the same conditions, the carrier KCO 3 / Al 2 o 3 Immobilized nano-palladium works best as a racemization catalyst.

Embodiment 8~ Embodiment 14

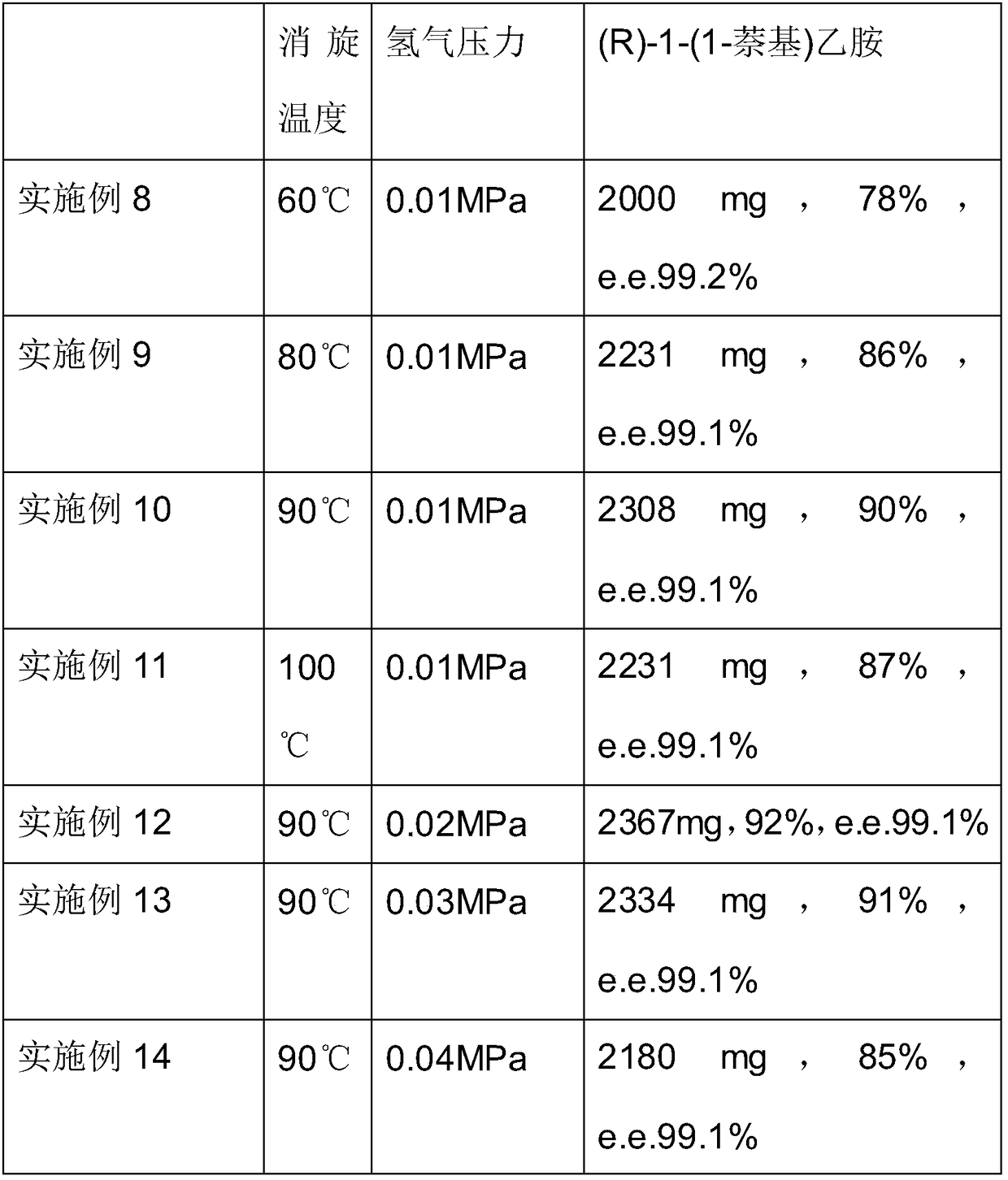

[0046] Each embodiment is basically the same as embodiment 1 (that is, the immobilized nano-palladium of embodiment 1 is used), and the differences are shown in Table 2.

[0047] Table 2

[0048]

[0049] It can be seen from Table 2 that in the case of using the same immobilized enzyme, the chemical enzyme resolution effect of Example 12 (at a racemization temperature of 90° C. and a hydrogen pressure of 0.02 MPa) is the best.

[0050] The following control experiment adopts embodiment 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com