A kind of black fungus dietary fiber fish ball and preparation method

A technology of dietary fiber and dietary fiber powder, which is applied in the field of new-type black fungus dietary fiber fish balls and preparation, can solve the problems of difficult wall breaking and poor effect, and achieve the effects of high nutritional value, saving raw materials, and good sensory properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Materials and Reagents

[0032] Black fungus: Provided by Hangzhou Huadan Agricultural Products Co., Ltd., with wrinkled fungus, autumn fungus, black fungus slag and broken fungus with poor appearance and taste as raw materials, dried and crushed through a 40-60 mesh sieve before use, and set aside; low-sodium compound salt ( food grade), xylitol (food grade), o-phthalaldehyde, potassium persulfate, ABTS + Solution, ethanol, etc.: Shanghai Aladdin Biochemical Technology Co., Ltd.; grass carp, hydroxypropyl starch, edible oil (olive oil), whey protein powder, cooking wine, monosodium glutamate: commercially available.

[0033] 2. Experimental equipment

[0034] ZN-100 desktop pulverizer, AL04 electronic balance, HH-2 water bath, DGG-9000B blast drying oven, desktop high-speed centrifuge, 721 spectrophotometer, VGT-227QT ultrasonic cleaner, multi-functional induction cooker, TMS -PRO Texture Analyzer.

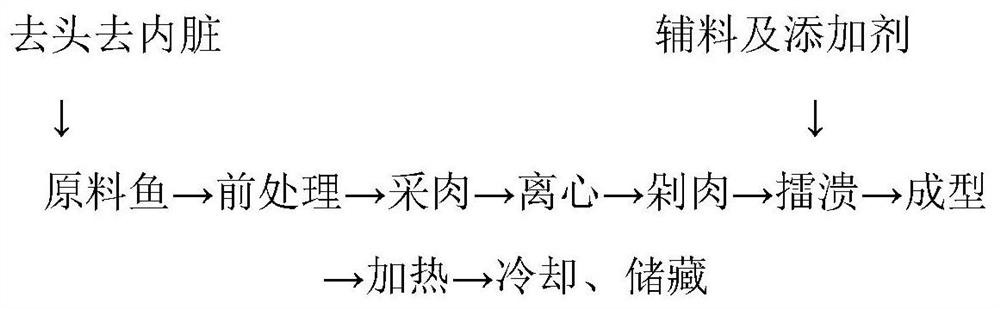

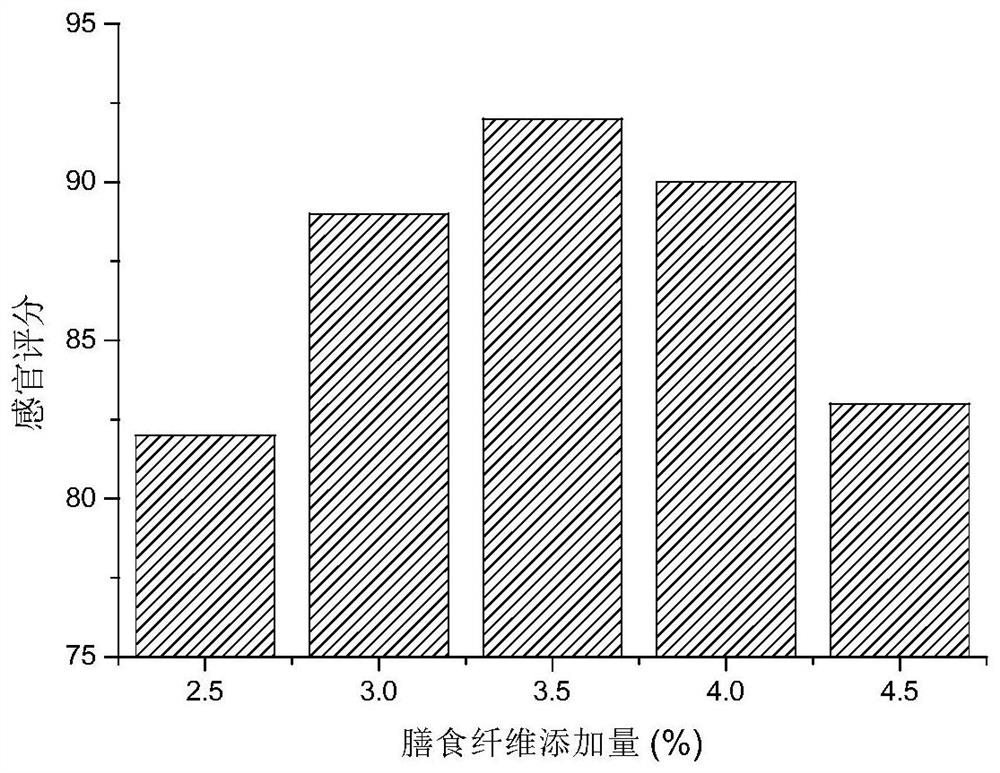

[0035] 3. Experimental method

[0036] 3.1 Preparation of blac...

Embodiment 2

[0158] The experimental operation is the same as step 3.1 of Example 1, the difference is that black fungus coarse powder (40-60 mesh) and water are mixed according to the mass ratio of 1:20, and microwave treatment is performed after ultra-low temperature freezing at -70°C for 1 hour, that is, at microwave frequency 2450MHz, microwave power 700W, treatment for 2min, then placed in -70℃ ultra-low temperature freezing for 1h, then microwave treatment, repeated treatment 4 times. Then the treated slurry is vacuum-dried at 50° C., crushed and passed through a 150-200 mesh sieve to obtain black fungus powder after microwave treatment. Mix the microwave-treated black fungus powder with water at a mass ratio of 1:80, use ultrasonic technology, ultrasonically treat at 60°C, 30KHz for 40 minutes, and vacuum-dry at 50°C to obtain black fungus dietary fiber powder. The clearance rate of ABTS is 71.57%, the combined water capacity is 25.02g / g, and the cholesterol adsorption capacity unde...

Embodiment 3

[0161] The experimental operation is the same as step 3.1 of Example 1, the difference is that the black fungus coarse powder (40-60 mesh) and water are in a mass ratio of 1:40, frozen at -80°C for 3 hours and then subjected to microwave treatment, that is, at microwave frequency 2450MHz, microwave power 900W, treatment for 4min, then placed in -80℃ ultra-low temperature freezing for 3h, then microwave treatment, repeated treatment 4 times. Then the treated slurry is vacuum-dried at 50° C., crushed and passed through a 150-200 mesh sieve to obtain black fungus powder after microwave treatment. After microwave treatment, the black fungus powder and water were mixed according to the mass ratio of 1:50, ultrasonic technology was used, ultrasonic treatment was performed at 50°C, 20KHz for 50 minutes, and vacuum drying was carried out at 50°C to obtain black fungus dietary fiber powder. The clearance rate of ABTS is 79.86%, the binding water capacity is 26.63g / g, and the cholestero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com