Preparation method of modified mixed basalt fiber concrete

A technology of basalt fiber and concrete, which is applied in the field of concrete processing, can solve the problems of poor fusion between polymer compounds and concrete, and achieve the effects of saving manpower and material resources, excellent performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

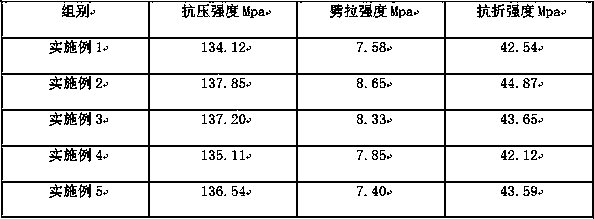

Examples

Embodiment 1

[0025] (1) Soak 24 parts by mass of 20-40mm basalt fibers in excess sulfuric acid for 50 minutes, drain the sulfuric acid, and immediately add 12 parts by mass of cyclohexanone peroxide, 16 parts by mass of cinnamaldehyde, 7 parts by mass of 50-80mm high crimp high wet modulus viscose fiber, 17 parts by mass of dimethylaminoethyl acrylate, the temperature is 44°C, the stirring rate is 160r / min and stirred for 38min; then add 29 parts by mass of titanic acid Ester coupling agent, the temperature is 75°C, the stirring speed is 320r / min and stirred for 1h to obtain the modified mixed fiber;

[0026] (2) Put 370 parts by mass of gravel and sand of 00 parts by mass into the mixer and stir for 60 seconds; put in 380 parts by mass of cement, 200 parts by mass of fly ash, and slag powder of 200 parts by mass Stir for 70s; 40 parts by mass of polycarboxylate superplasticizer, 180 parts by mass of water, and 10 parts by mass of diethylenetriaminepentamethylenephosphonic acid are added t...

Embodiment 2

[0028] (1) Soak 30 parts by mass of 20-40mm basalt fiber in excess sulfuric acid for 40 minutes, drain the sulfuric acid, and immediately add 14 parts by mass of cyclohexanone peroxide, 15 parts by mass of perillaldehyde, 9 parts by mass of 50-80mm high crimp high wet modulus viscose fiber, 20 parts by mass of dimethylaminoethyl acrylate, the temperature is 48°C, the stirring rate is 200r / min and stirred for 40min; then add 30 parts by mass of titanium Ester coupling agent, the temperature is 80°C, the stirring speed is 380 / min and stirred for 2h to obtain the modified mixed fiber;

[0029] (2) Put 420 parts by mass of crushed stone and 800 parts by mass of sand into the mixer and stir for 65 seconds; put in 450 parts by mass of cement, 180 parts by mass of fly ash, and 100 parts by mass of mineral powder and mix Stir for 80s; 42 parts by mass of lignosulfonate water reducer, 190 parts by mass of water, and 9 parts by mass of diethylenetriaminepentamethylenephosphonic acid are...

Embodiment 3

[0031] (1) Soak 26 parts by mass of 20-40mm basalt fibers in excess sulfuric acid for 60 minutes, drain the sulfuric acid, and immediately add 15 parts by mass of cyclohexanone peroxide, 20 parts by mass of veratraldehyde, 10 parts by mass of 50-80mm high crimp high wet modulus viscose fiber, 15 parts by mass of dimethylaminoethyl acrylate, the temperature is 41°C, the stirring rate is 100r / min and stirred for 32min; then add 22 parts by mass of titanium Ester coupling agent, the temperature is 65°C, the stirring rate is 300r / min and stirred for 1h to obtain the modified mixed fiber;

[0032] (2) Put 430 parts by mass of crushed stone and 850 parts by mass of sand into the mixer and stir for 80 seconds; put in 350 parts by mass of cement, 220 parts by mass of fly ash, and 120 parts by mass of mineral powder and mix Stir for 75s; 45 parts by mass of polycarboxylate superplasticizer, 170 parts by mass of water, and 8 parts by mass of diethylenetriaminepentamethylenephosphonic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com