Perovskite light emitting diode based on ultraviolet thermal annealing process and a preparation method thereof

A light-emitting diode, perovskite technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor stability, large leakage current, weak device brightness, etc., and achieve strong resistance to water and oxygen corrosion. , The effect of solving large performance deviation and improving brightness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

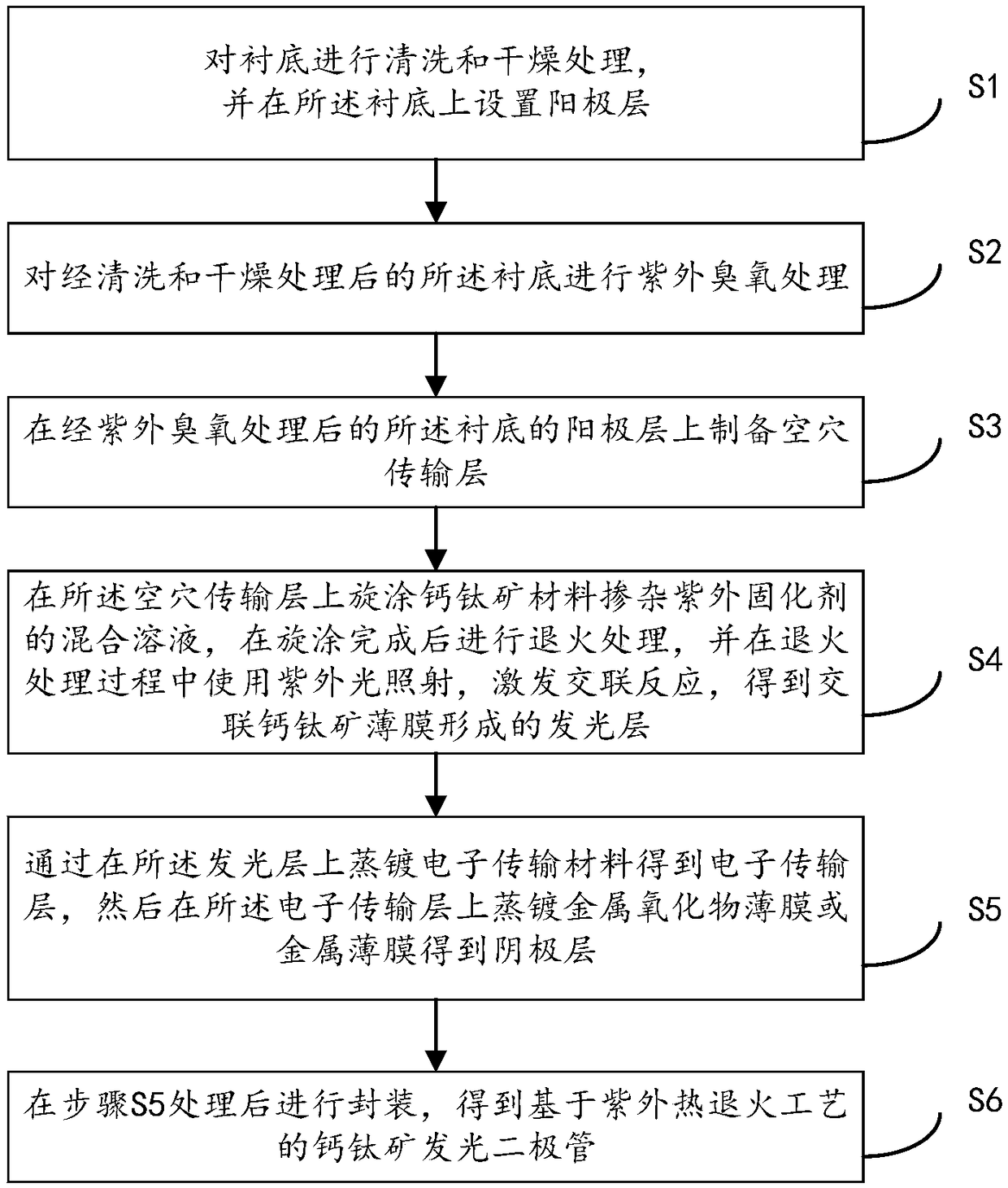

[0034] A preparation method of perovskite light emitting diode based on ultraviolet thermal annealing process, such as figure 1 Shown, including:

[0035] S1, cleaning and drying the substrate, and setting an anode layer on the substrate;

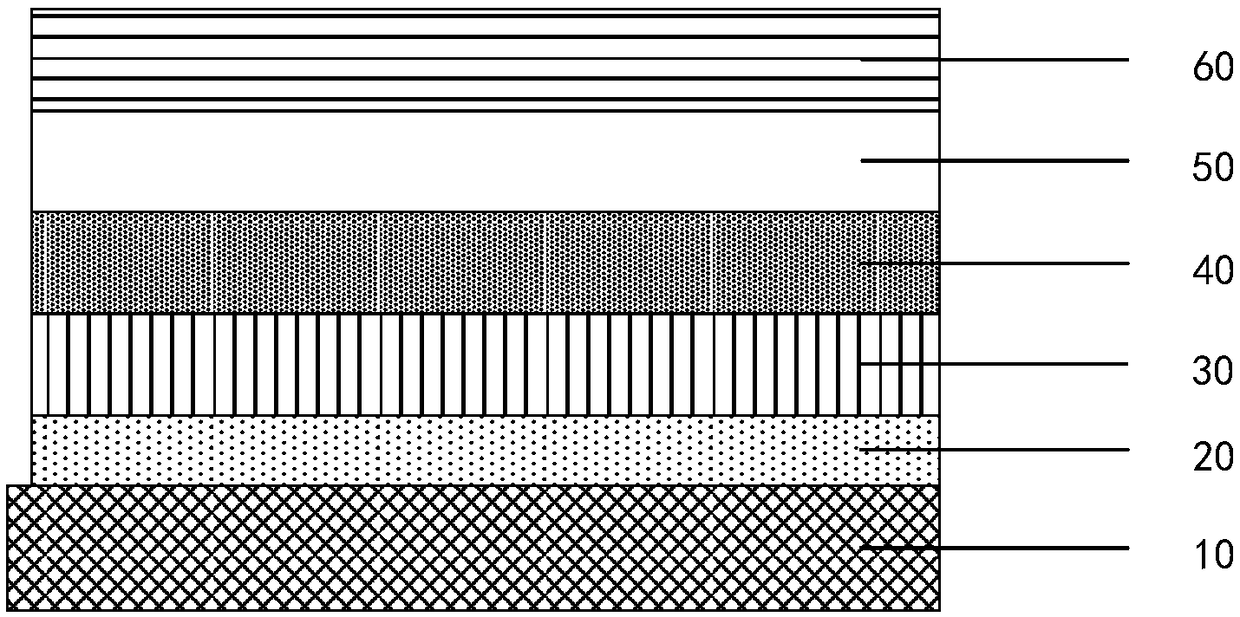

[0036] S2, performing ultraviolet ozone treatment on the substrate 10 after the cleaning and drying treatment;

[0037] S3: preparing a hole transport layer 30 on the anode layer 20 of the substrate 10 after the ultraviolet ozone treatment;

[0038] S4. Spin-coating a mixed solution of perovskite material doped with ultraviolet curing agent on the hole transport layer 30, and perform annealing treatment after the spin coating is completed, and irradiate with ultraviolet light during the annealing treatment to stimulate the cross-linking reaction , To obtain a light-emitting layer 40 formed of a cross-linked perovskite film;

[0039] S5. Obtain an electron transport layer 50 by evaporating an electron transport material on the light-emitting layer 40...

Embodiment 1

[0053] This embodiment provides a method for manufacturing a perovskite light-emitting diode based on an ultraviolet thermal annealing process, including:

[0054] Step 1. Use transparent conductive substrate ITO glass as the substrate 10, ultrasonically clean the substrate 10 with ethanol solution, acetone solution, and deionized water, and then use dry nitrogen to blow dry, and remove the substrate 10 The upper ITO film is used as the anode layer 20 of the diode device; the resistance of the ITO film on the transparent conductive substrate ITO glass used is 10Ω / sq;

[0055] Step 2. Perform ultraviolet ozone treatment on the substrate 10 after cleaning and drying for 15 minutes;

[0056] Step 3. Spin-coating PEDOT:PSS on the anode layer 20 of the substrate 10 after the ultraviolet ozone treatment, and then perform annealing treatment to form a hole transport layer 30;

[0057] Step 4. Transfer to a nitrogen environment (such as a glove box with a 99.9% nitrogen atmosphere), and spin-...

Embodiment 2

[0061] This embodiment provides a method for manufacturing a perovskite light-emitting diode based on an ultraviolet thermal annealing process, including:

[0062] Step 1. Use the transparent conductive substrate ITO glass as the substrate 10, clean and dry the substrate 10, and use the ITO film on the substrate 10 as the anode layer 20 of the diode device; the transparent conductive The resistance of the ITO film on the substrate ITO glass is 10Ω / sq;

[0063] Step 2. Perform ultraviolet ozone treatment on the substrate 10 after cleaning and drying for 15 minutes;

[0064] Step 3. Spin-coating PEDOT:PSS on the anode layer 20 of the substrate 10 after the ultraviolet ozone treatment, and then perform annealing treatment to form a hole transport layer 30;

[0065] Step 4. Transfer to a nitrogen environment (such as a glove box with a 99.9% nitrogen atmosphere), and spin-coat MAPbBr on the hole transport layer 30 3 A mixed solution of 3,3',4,4'-benzophenone tetracarboxylic dianhydride do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com