A preparation method based on rectorite-loaded spherical nano-calcium salt oxidant

A rectorite and spherical technology is applied in the field of preparation based on rectorite-loaded spherical nano calcium salt oxidant, which can solve the problems of inability to remove moisture and small removal effect, and achieve easy operation, strong adsorption, and good dispersibility. and migratory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

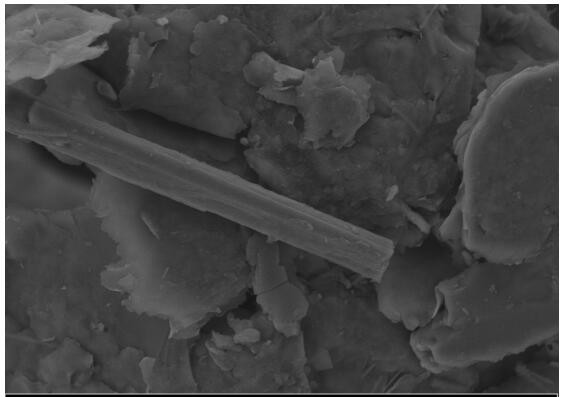

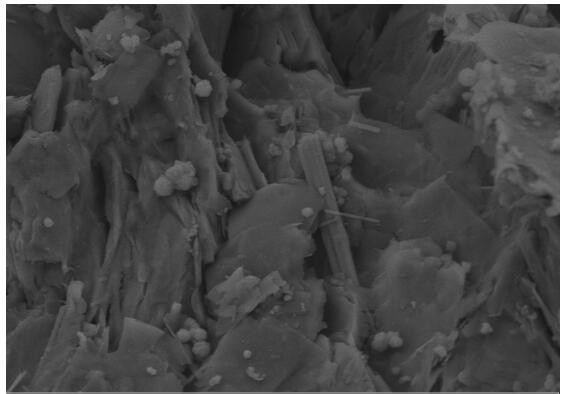

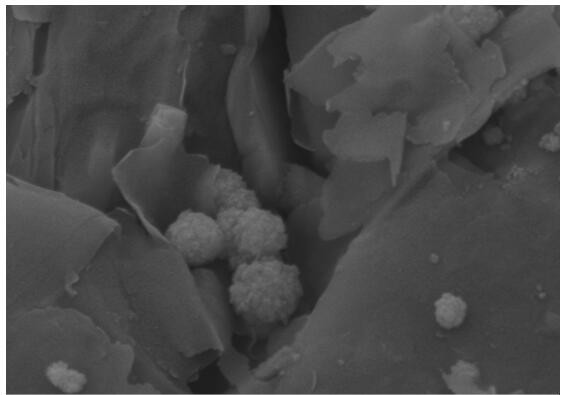

Image

Examples

Embodiment 1

[0035] A preparation method based on rectorite loaded spherical nano calcium peroxide, comprising the following steps:

[0036] (1) Pretreatment of rectorite: at room temperature, take 5 g of rectorite, add distilled water at a solid-to-liquid ratio of 1:10, and stir for 20 minutes with a magnetic stirrer under ultrasonic conditions to prepare rectorite suspension liquid; the obtained rectorite suspension was left to age for 12 h, then centrifuged and washed with absolute ethanol and deionized water, and the obtained solid was dried at 105°C for 24 h, ground to 70 μm, and set aside.

[0037] (2), preparation of spherical nano calcium peroxide:

[0038] A. Weigh 3 g of calcium salt, add distilled water according to the solid-to-liquid ratio of 1:10, add 15 g of PEG 1000 and ammonia water with a mass fraction of 25%, and mechanically stir at 300 r / min for 1 h under ultrasonic conditions to mix The substances are thoroughly mixed;

Embodiment 2

[0043] A preparation method based on rectorite loaded spherical nano-calcium hydroxide, comprising the following steps:

[0044] (1) Pretreatment of rectorite: at room temperature, take 7 g of rectorite, add distilled water at a solid-to-liquid ratio of 1:12, and stir for 30 minutes with a magnetic stirrer under ultrasonic conditions to prepare rectorite suspension liquid; the obtained rectorite suspension was left to age for 18 h, then centrifuged and washed with absolute ethanol and deionized water, and the obtained solid was dried at 105°C for 24 h, ground to 80 μm, and set aside.

[0045] (2) Preparation of spherical nano calcium hydroxide

[0046] A. Weigh 5 g of calcium salt, add distilled water according to the solid-to-liquid ratio of 1:10, add 25 g of PEG 1000 and ammonia water with a mass fraction of 25%, and mechanically stir at 500 r / min for 1.5 h under ultrasonic conditions to mix The substances are thoroughly mixed;

Embodiment 3

[0050] A preparation method based on rectorite loaded spherical nano-calcium salt oxidant, comprising the following steps:

[0051] (1) Pretreatment of rectorite: at room temperature, take 7 g of rectorite, add distilled water at a solid-to-liquid ratio of 1:12, and stir for 30 minutes with a magnetic stirrer under ultrasonic conditions to prepare rectorite suspension liquid; the obtained rectorite suspension was left to age for 18 h, then centrifuged and washed with absolute ethanol and deionized water, and the obtained solid was dried at 105°C for 24 h, ground to 80 μm, and set aside.

[0052] (2) Preparation of spherical nano calcium hydroxide

[0053] A. Weigh 5 g of calcium salt, add distilled water according to the solid-to-liquid ratio of 1:10, add 25 g of PEG·1000 and ammonia water with a mass fraction of 25%, and perform mechanical stirring at 500 r / min for 1.5 h under ultrasonic conditions to mix The substances are thoroughly mixed;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com