Method for preparing N-acetvlneuraminic acid through integrated polysialic acid separation and purification

A technology of acetylneuraminic acid and polysialic acid, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar compounds with non-glycosyl groups, etc., can solve problems such as high price, achieve low cost, simplify production steps, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

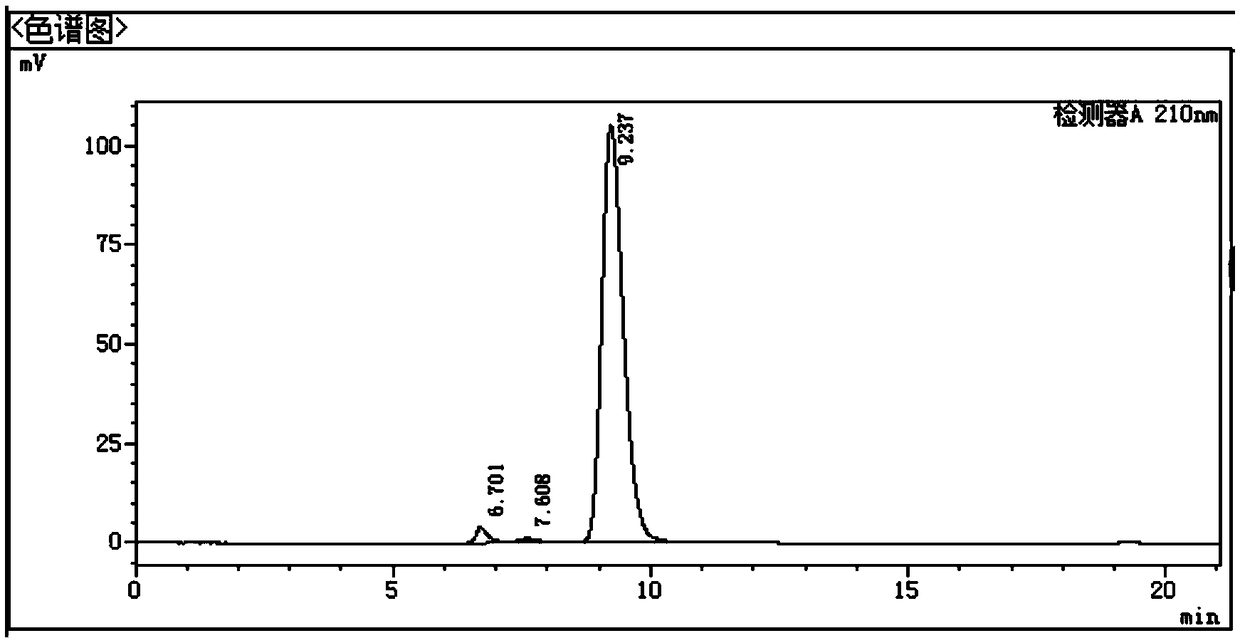

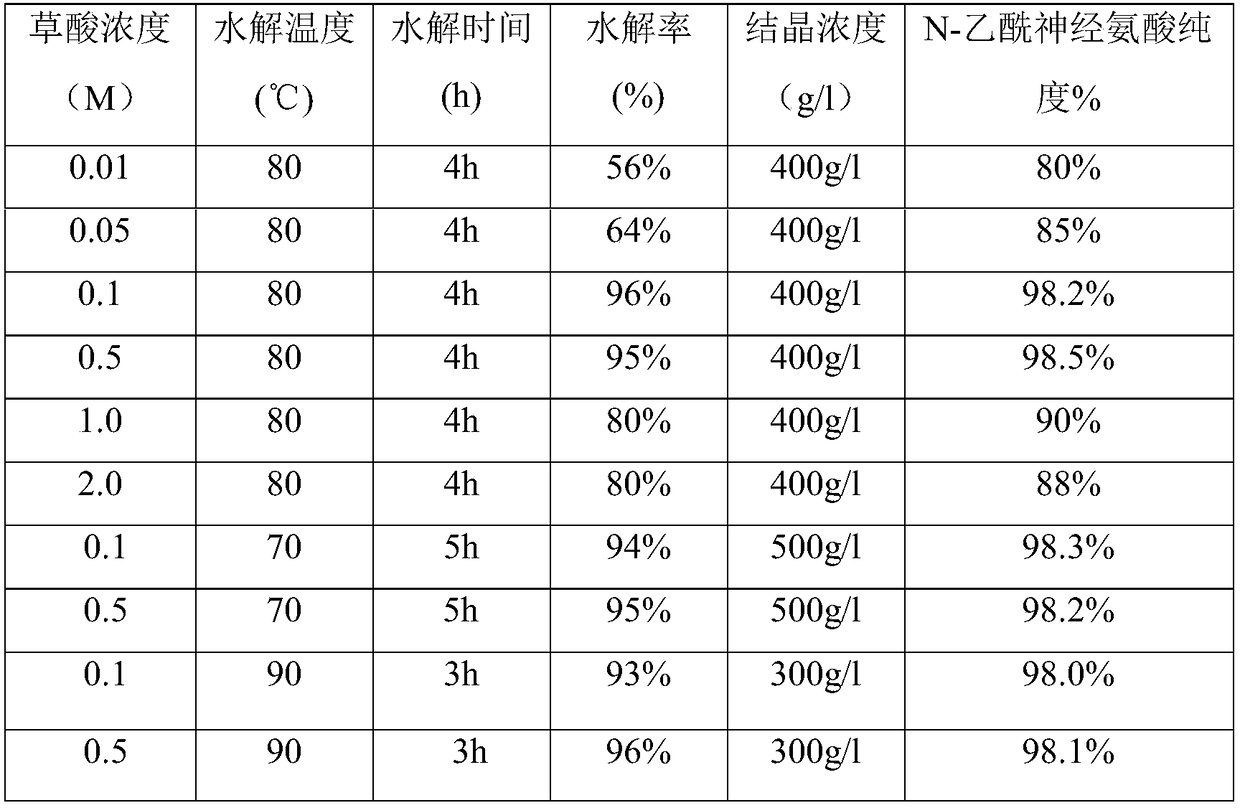

[0028] The method for the separation and purification of polysialic acid integrated in this example to prepare N-acetylneuraminic acid is as follows:

[0029] 1. Pretreatment of polysialic feed liquid: polysialic acid derived from microbial fermentation is used as raw material, and the feed liquid containing polysialic acid is obtained through membrane filtration and sterilization steps;

[0030] 2. Hydrolysis of polysialic acid: add 0.1M oxalic acid aqueous solution to the pretreated fermentation broth containing polysialic acid, heat the temperature to 80°C, and heat for 4 hours to hydrolyze polysialic acid into N-acetylneuramine acid;

[0031] 3. Feed liquid neutralization: Add calcium hydroxide aqueous solution to the above hydrolyzed aqueous solution, and neutralize the pH of the solution to 7.0.

[0032] 4. Precipitate protein and salt: Add 2 times the volume of ethanol to the above neutralized solution to precipitate impurity proteins and some salt impurities that are ...

Embodiment 2

[0036] The method for the separation and purification of polysialic acid integrated in this example to prepare N-acetylneuraminic acid is as follows:

[0037] 1. Pretreatment of polysialic feed liquid: polysialic acid derived from microbial fermentation is used as raw material, and the feed liquid containing polysialic acid is obtained through membrane filtration and sterilization steps;

[0038] 2. Hydrolysis of polysialic acid: Add 0.5M oxalic acid aqueous solution to the pretreated fermentation broth containing polysialic acid, heat the temperature to 80°C for 4 hours, and hydrolyze polysialic acid into N-acetylneuramine acid;

[0039] 3. Feed liquid neutralization: Add calcium bicarbonate aqueous solution to the above hydrolyzed aqueous solution, and neutralize the pH of the solution to 7.0.

[0040] 4. Precipitate protein and salt: Add 3 times the volume of ethanol to the above neutralized solution to precipitate impurity protein and some salt impurities insoluble in eth...

Embodiment 3

[0044] The method for the separation and purification of polysialic acid integrated in this example to prepare N-acetylneuraminic acid is as follows:

[0045] 1. Pretreatment of polysialic feed liquid: polysialic acid derived from microbial fermentation is used as raw material, and the feed liquid containing polysialic acid is obtained through membrane filtration and sterilization steps;

[0046] 2. Hydrolysis of polysialic acid: add 0.1M oxalic acid aqueous solution to the pretreated fermentation broth containing polysialic acid, heat the temperature to 70°C for 5 hours, and hydrolyze polysialic acid into N-acetylneuramine acid;

[0047] 3. Feed liquid neutralization: Add calcium hydroxide aqueous solution to the above hydrolyzed aqueous solution, and neutralize the pH of the solution to 7.0.

[0048] 4. Precipitate protein and salt: Add 4 times the volume of ethanol to the above neutralized solution to precipitate impurity proteins and some salt impurities that are insolubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com