Energy-saving gasoline additive and preparation method and application thereof

A technology of gasoline additive and rust inhibitor, applied in the field of gasoline additive, can solve the problems of non-clean gasoline not entering the market, insufficient combustion of vehicles, large amount of methanol, etc., to reduce pollutant emissions, reduce environmental pollution, and reduce combustion The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

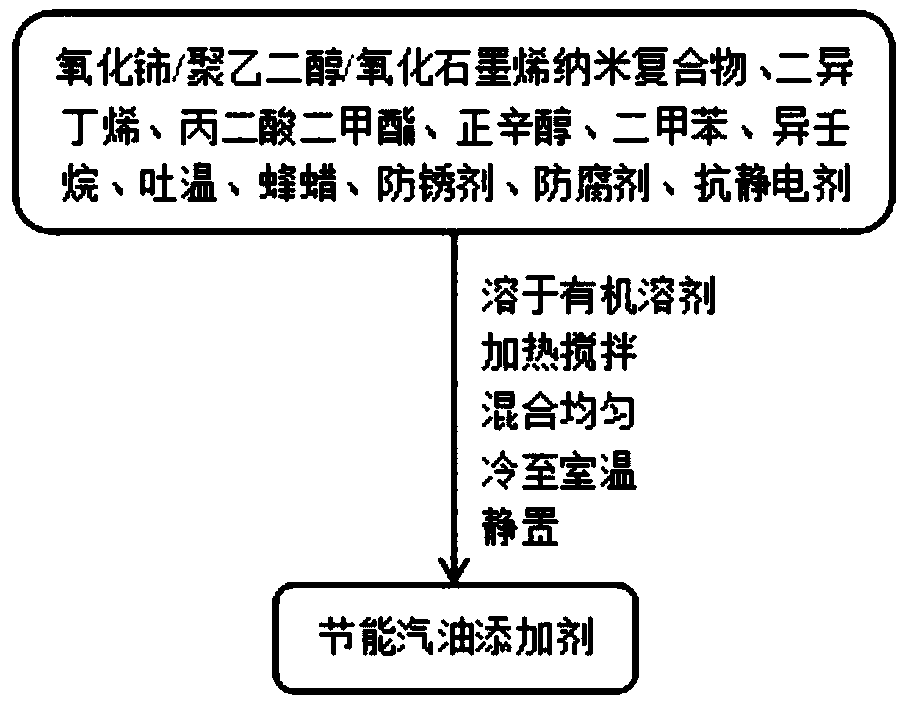

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 energy-saving gasoline additive

[0029] Raw material composition: 30 parts of cerium oxide / polyethylene glycol / graphene oxide nanocomposite; 10 parts of diisobutylene; 10 parts of dimethyl malonate; 20 parts of n-octanol; 10 parts of xylene; 5 parts of isononane ; 5 parts of Tween; 10 parts of beeswax; 10 parts of triethanolamine borate; 5 parts of potassium benzoate; 5 parts of fatty alcohol polyoxyethylene ether; 30 parts of triethanolamine.

[0030] Cerium oxide / polyethylene glycol / graphene oxide nanocomposites were prepared by the following method:

[0031] (1) adopt improved Hummers method to prepare graphene oxide;

[0032] (2) Preparation of polyethylene glycol / graphene oxide: Take 3 mol of graphene oxide aqueous dispersion and add it to the reaction kettle, ultrasonically treat it for 30 minutes, add 2 mol of polyethylene glycol aqueous solution, mix well, heat to 70°C, stir React for 10 hours, filter, and wash the solid with d...

Embodiment 2

[0035] The preparation of embodiment 2 energy-saving gasoline additives

[0036] Raw material composition: 50 parts of cerium oxide / polyethylene glycol / graphene oxide nanocomposite; 30 parts of diisobutylene; 15 parts of dimethyl malonate; 30 parts of n-octanol; 30 parts of xylene; 15 parts of isononane ; 15 parts of Tween; 30 parts of beeswax; 15 parts of triethanolamine laurate; 15 parts of propyl paraben; 15 parts of SP; 50 parts of ethylene glycol monomethyl ether.

[0037] Cerium oxide / polyethylene glycol / graphene oxide nanocomposites were prepared by the following method:

[0038] (1) adopt improved Hummers method to prepare graphene oxide;

[0039] (2) Preparation of polyethylene glycol / graphene oxide: Take 5 mol of graphene oxide aqueous dispersion and add it to the reaction kettle, ultrasonically treat it for 30 minutes, add 2 mol of polyethylene glycol aqueous solution, mix well, heat to 70°C, stir React for 10 hours, filter, and wash the solid with deionized water...

Embodiment 3

[0042] The preparation of embodiment 3 energy-saving gasoline additives

[0043] Raw material composition: 34 parts of cerium oxide / polyethylene glycol / graphene oxide nanocomposite; 13 parts of diisobutylene; 11 parts of dimethyl malonate; 22 parts of n-octanol; 12 parts of xylene; 7 parts of isononane ; 7 parts of Tween; 15 parts of beeswax; 12 parts of triethanolamine oleate; 8 parts of deoxyacetic acid; 6 parts of SN; 35 parts of ethylene glycol monobutyl ether.

[0044] Cerium oxide / polyethylene glycol / graphene oxide nanocomposites were prepared by the following method:

[0045] (1) adopt improved Hummers method to prepare graphene oxide;

[0046] (2) Preparation of polyethylene glycol / graphene oxide: Take 4mol graphene oxide water dispersion and add it to the reaction kettle, ultrasonically treat it for 30min, add 2mol polyethylene glycol aqueous solution, mix well, heat to 70°C, stir React for 10 hours, filter, and wash the solid with deionized water to obtain;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com