W-N nano composite-structured coating for miniature end milling cutters and preparation method thereof

A nano-composite, W-N technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of shortened tool life, poor processing quality, etc., and achieve the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

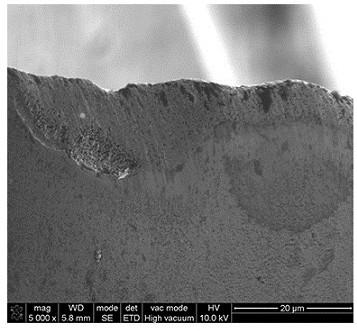

[0032] Select a micro-drill with a diameter of 0.3mm to deposit a W-N nanocomposite structure coating by DC magnetron sputtering. The steps are as follows:

[0033] 1. Small-diameter knife surface pretreatment: ultrasonically clean the micro-drill in acetone and absolute ethanol for 10 minutes, dry it with hot air, clamp it on a three-dimensionally rotatable planetary carrier, and send it into the chamber;

[0034] 2. Vacuumize the chamber: firstly pump the chamber to a vacuum of 4×10 through mechanical pump and molecular pump -5 Below mbar, then set the temperature of the infrared heating tube to 600°C, set the heating time to 30min, and then pump the chamber vacuum to 4×10 -5 Below mbar, set the temperature of the infrared heating tube to 550°C and the heating time to 30 minutes. After heating again, the vacuum degree of the chamber is evacuated to 4×10 -5 Below mbar, fully remove the volatile impurities on the surface of the chamber and the small diameter knife;

[0035] 3....

Embodiment 2

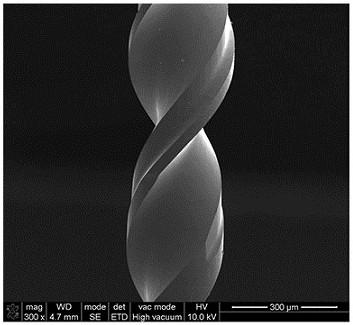

[0042] Select a micro-drill with a diameter of 0.15mm to deposit a W-N nanocomposite structure coating by DC magnetron sputtering, and the steps are as follows:

[0043] 1. Small-diameter knife surface pretreatment: the same as in Example 1;

[0044] 2. Vacuumize the chamber: the same as in Example 1;

[0045] 3. Ion etching on the surface of the small-diameter knife: Before depositing the film, the arc-enhanced glow discharge technology is used to perform ion cleaning and etching on the cemented carbide small-diameter knife to enhance the bonding ability of the film base. The conditions for ion etching are: (1) The arc target used as the electron source adopts a Ti target with a purity of more than 99%, and the target current is 90A; (2) The planetary frame on which the small-diameter knife is placed is connected to the negative pole of the pulse power supply, and bipolar pulses are used. The negative bias voltage gradually increases from -50V to -300V, the positive voltage ...

Embodiment 3

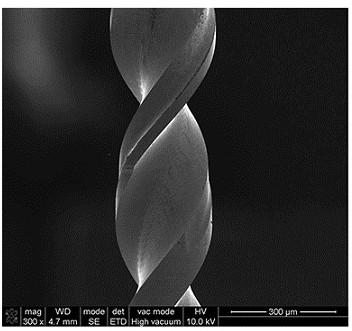

[0051] Select a micro-drill with a diameter of 0.15mm to deposit a W-N nanocomposite structure coating by high-power pulse magnetron sputtering. The steps are as follows:

[0052] 1. Small-diameter knife surface pretreatment: the same as in Example 1;

[0053] 2. Vacuumize the chamber: the same as in Example 1;

[0054] 3. Ion etching on the surface of the small-diameter knife: Before depositing the film, the cemented carbide substrate is ion-cleaned and etched using arc-enhanced glow discharge technology to enhance the bonding ability of the film substrate. The conditions for ion etching are: (1) The arc target used as the electron source adopts a Ti target with a purity of more than 99%, and the target current is 70A; (2) The planetary frame on which the small diameter knife is placed is connected to the negative pole of the pulse power supply, and a bipolar pulse is used. The negative bias voltage gradually increases from -50V to -300V, the positive voltage is +20V, the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com