A high-wear-resistant composite magnetic material for automobile ABS system and preparation method thereof

A composite magnetic material and ABS system technology, which is applied in the field of high wear-resistant composite magnetic material and preparation of automobile ABS system, can solve the problems of easy entry of sand and gravel, large magnetic friction loss, influence of magnetic performance inductive signal, etc., to save processing. Cost and processing time, high magnetic content, effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

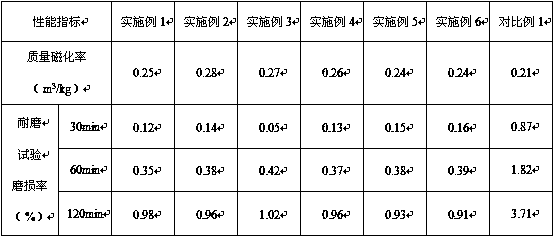

Examples

Embodiment 1

[0031] (1) First add iron salt and lanthanum salt into the solvent, stir and dissolve until the solution is uniform and transparent, then add polyvinylpyrrolidone, mix and stir evenly, and obtain a transparent and viscous spinning stock solution; iron salt is ferric nitrate; lanthanum The salt is lanthanum nitrate; the solvent is ethanol;

[0032] Wherein: 13 parts by weight of iron salt, 13 parts by weight of lanthanum salt, 52 parts by weight of solvent, 22 parts by weight of polyvinylpyrrolidone;

[0033] (2) Electrospinning the spinning stock solution obtained in step (1) to obtain composite nanofibers; the voltage of electrospinning is 13kV, the receiving distance is 25cm, and the average diameter of the composite nanofibers is 180nm;

[0034] (3) Segmentally calcined the composite nanofibers prepared in step (2) to obtain lanthanum ferrite nanotubes; the segmented calcination is divided into three stages, the temperature of the first stage is 430°C, the holding time is 5...

Embodiment 2

[0039] (1) First add iron salt and lanthanum salt into the solvent, stir and dissolve until the solution is uniform and transparent, then add polyvinylpyrrolidone, mix and stir evenly, and obtain a transparent and viscous spinning stock solution; iron salt is ferric sulfate; lanthanum The salt is lanthanum chloride; the solvent is acetone;

[0040] Wherein: 11 parts by weight of iron salt, 11 parts by weight of lanthanum salt, 57 parts by weight of solvent, and 21 parts by weight of polyvinylpyrrolidone;

[0041] (2) Electrospinning the spinning stock solution obtained in step (1) to obtain composite nanofibers; the voltage of electrospinning is 11kV, the receiving distance is 22cm, and the average diameter of the composite nanofibers is 150nm;

[0042] (3) Segmentally calcined the composite nanofibers prepared in step (2) to obtain lanthanum ferrite nanotubes; the segmented calcination is divided into three stages, the temperature of the first stage is 410°C, the holding time...

Embodiment 3

[0047] (1) First add iron salt and lanthanum salt into the solvent, stir and dissolve until the solution is uniform and transparent, then add polyvinylpyrrolidone, mix and stir evenly, and obtain a transparent and viscous spinning stock solution; the iron salt is ferric chloride; Lanthanum salt is lanthanum carbonate; Solvent is chloroform;

[0048] Wherein: 13 parts by weight of iron salt, 14 parts by weight of lanthanum salt, 49 parts by weight of solvent, 24 parts by weight of polyvinylpyrrolidone;

[0049] (2) Electrospinning the spinning stock solution obtained in step (1) to obtain composite nanofibers; the voltage of electrospinning is 14kV, the receiving distance is 28cm, and the average diameter of the composite nanofibers is 250nm;

[0050] (3) Segmentally calcined the composite nanofibers prepared in step (2) to obtain lanthanum ferrite nanotubes; the segmental calcination is divided into three stages, the first stage temperature is 440°C, the holding time is 4h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com