Method for realizing controllable free radical polymerization based on Finkelstein reaction

A free radical and reaction technology, applied in the field of controlled free radical polymerization based on Finkelstein reaction, can solve the problems of photosensitive organic iodine compounds, colored products, expensive initiators, etc., achieve low price, rapid reaction, and reduce reaction cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

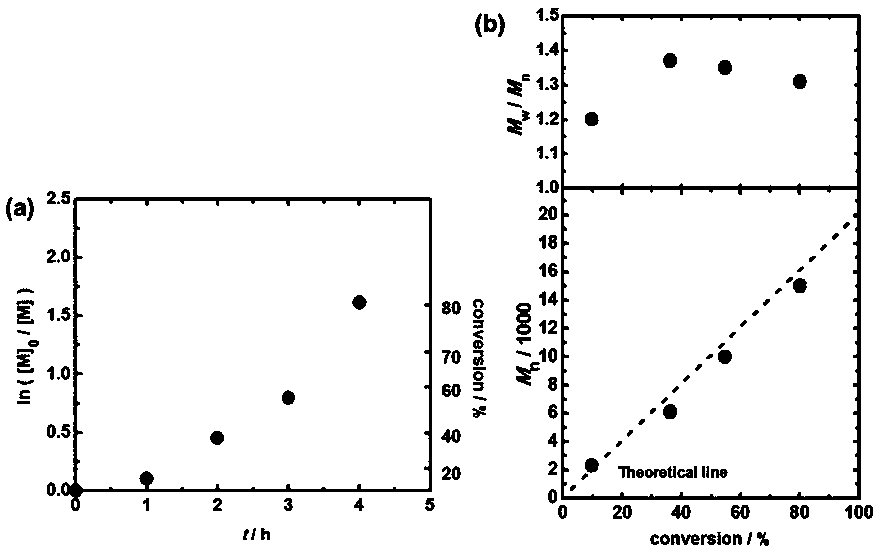

Embodiment 1

[0042] First, 0.04 mmol of ethyl α-bromophenylacetate, 0.04 mmol of sodium iodide, 8 mmol of methyl methacrylate, azo compound V65 (R = CH 2 CH(CH 3 ) 2 ) 0.01mmol, and N-iodosuccinimide 0.001mmol were sequentially added to the reaction device. Under stirring, nitrogen gas was bubbled into the above solution for 10 min. Afterwards, place the reaction apparatus at 60 o C, react for a certain time, and take out part of the reaction solution every certain reaction time. The monomer conversion rate of the reaction solution was detected by proton nuclear magnetic resonance. The molecular mass and dispersion coefficient of the obtained polymer were detected by gel permeation chromatography. The reaction kinetics and corresponding results are shown in figure 1 .

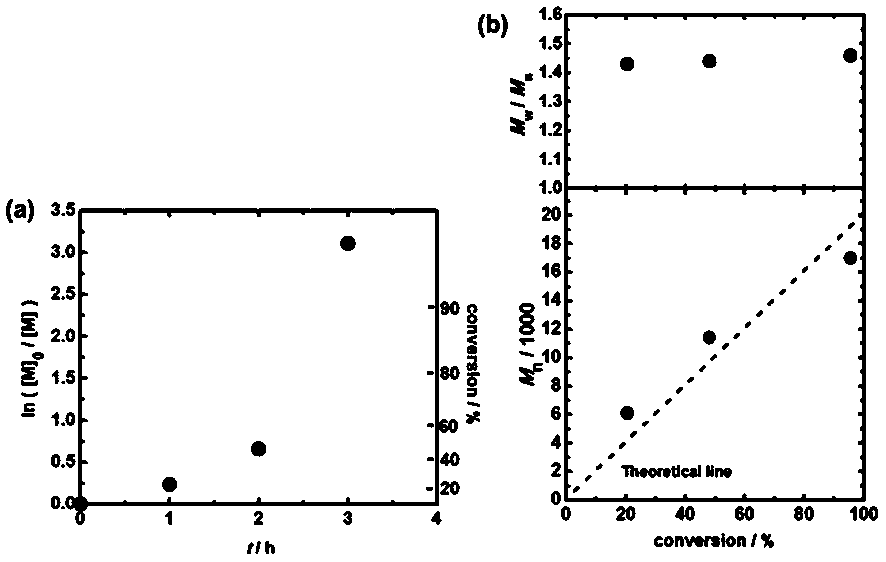

Embodiment 2

[0044] Concrete experimental procedure is identical with embodiment 1, and reaction temperature is promoted to 70 o c. The reaction kinetics and corresponding results are shown in figure 2 .

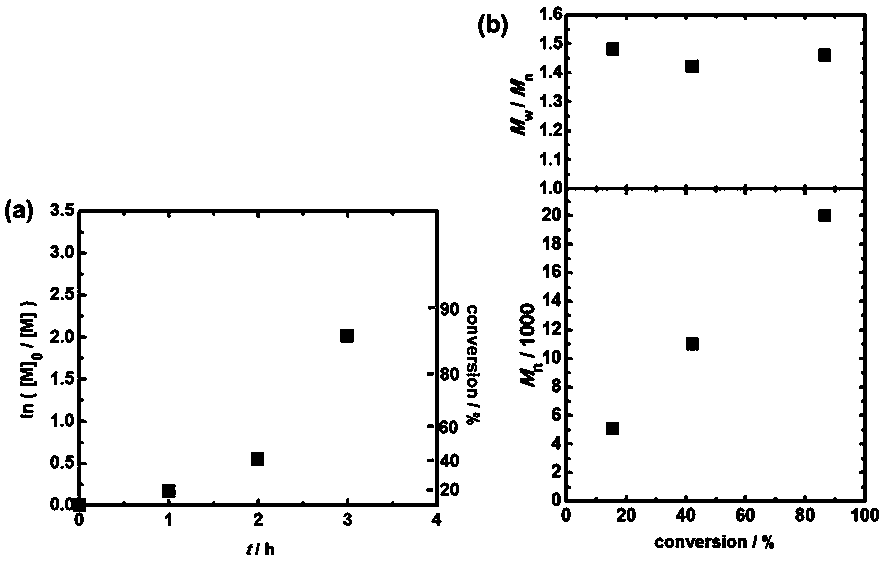

Embodiment 3

[0046] The specific experimental procedure is the same as in Example 1, and the reaction monomer methyl methacrylate is replaced with benzyl methacrylate. The reaction kinetics and corresponding results are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com