Preparation method of alpha-cypermethrin upconversion fluorescent sensing material

A technology of cis-cypermethrin and fluorescent sensing, which is applied in the direction of luminescent materials, material analysis and material analysis through optical means, can solve the problems of long degradation cycle, long-term existence, large dosage, etc., and achieve high selectivity and low cost , highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

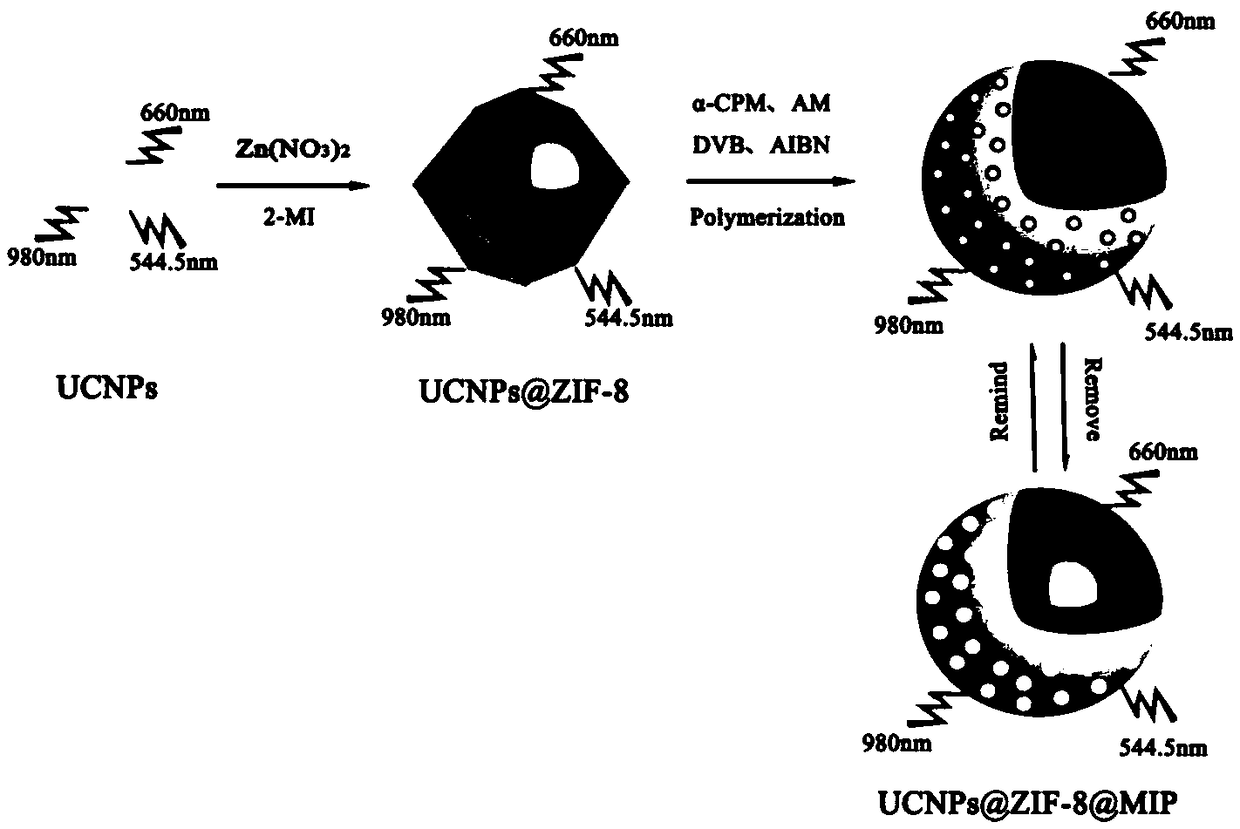

Method used

Image

Examples

Embodiment 1

[0035] (1) 1mmol rare earth acetate RE(C 2 h 3 o 2 ) 3 (RE=78%Y, 20%Yb, 2%Er), 17mL 1-octadecene, 6mL oleic acid were placed in a 100mL three-neck flask, under stirring, raise the temperature of the system to 160°C and react for 30min; stop heating , naturally cooled to room temperature, then slowly dropwise added 10mL of methanol mixed solution containing 4mmol ammonium fluoride and 2.5mmol NaOH into the three-necked flask, and kept stirring vigorously at room temperature for 30min, then raised the system temperature to 75°C, remove methanol; after the methanol is removed, quickly raise the temperature to 300°C, and react at this temperature for 1 hour. After the reaction is completed, cool the system naturally to room temperature, then precipitate the product with excess ethanol, and wash the product three times with ethanol , and finally put the product into a vacuum drying oven at 55°C for 12 hours to obtain UCNPs;

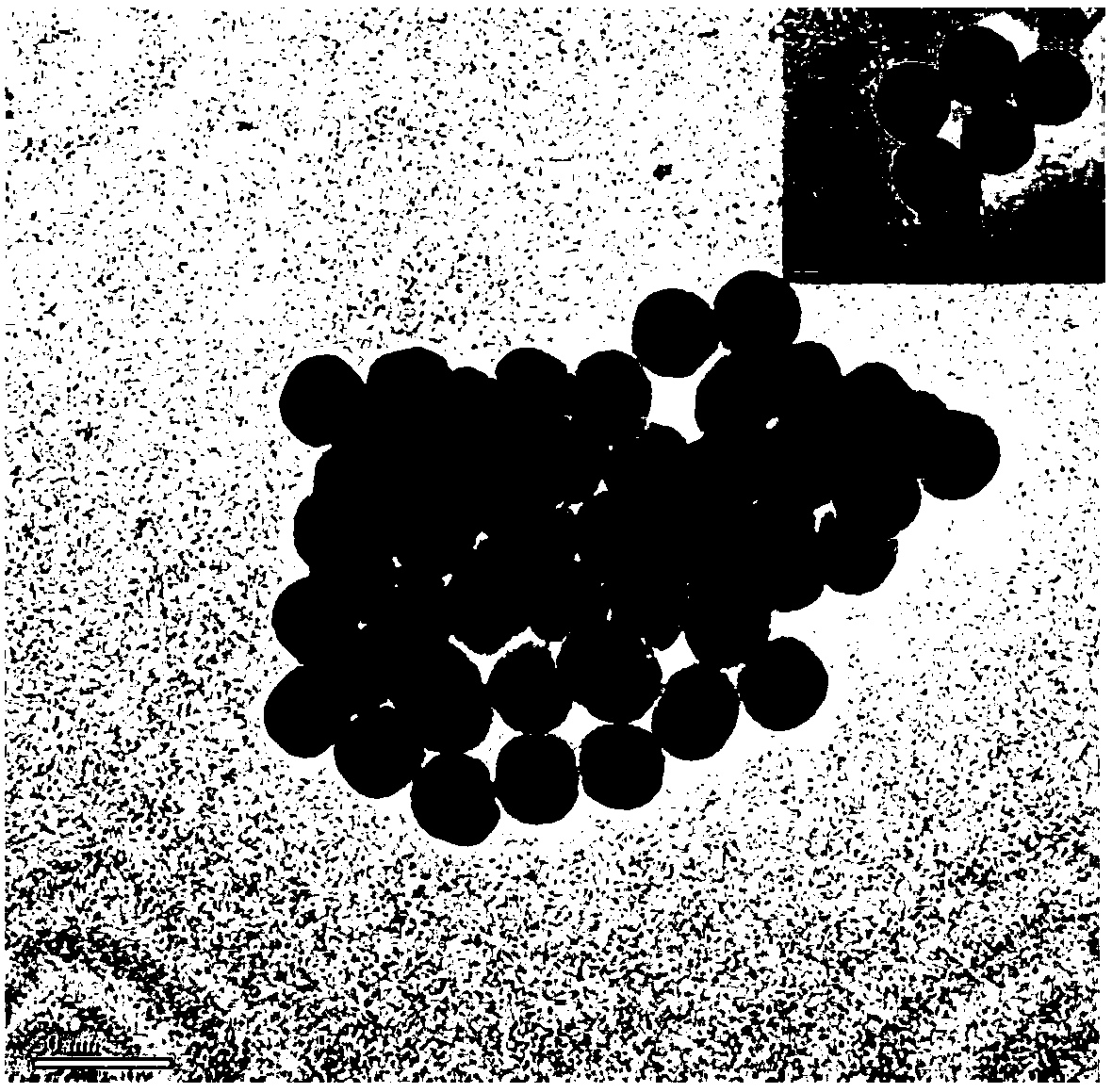

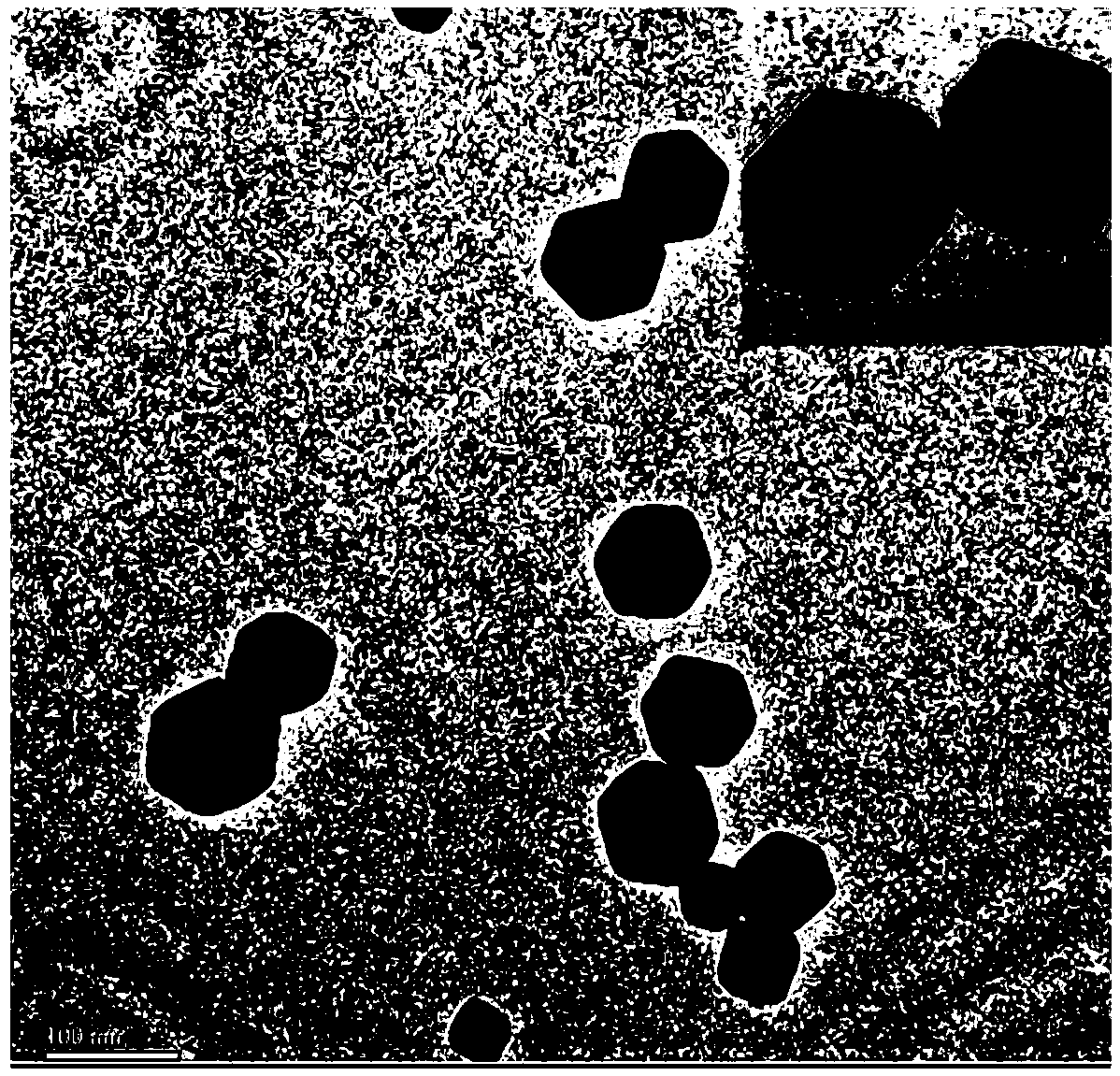

[0036] (2) Firstly, 50 mg of the up-conversion mater...

Embodiment 2

[0044] To study the dynamic properties of the sensing material such as Figure 8 . Weigh 1 mg of imprinted polymer MIP and non-imprinted polymer NIP, place at the bottom of a 4 mL centrifuge tube and add 12 mg L -1 cis-cypermethrin standard solution 2mL each, seal the centrifuge tube with parafilm and fix it on a horizontal shaker for different time (10min, 20min, 30min, 40min, 50min, 60min, 70min, 80min), then immediately excite it with an external 980nm The fluorescent spectrophotometer of the instrument was used to measure the fluorescence intensity of the material before and after adsorption, and the adsorption kinetic curve of the fluorescent imprinted polymer material was drawn. Such as Figure 8 As shown, in the process of adsorbing cis-cypermethrin, with the extension of time, the F of the fluorescent imprinted polymer material MIP and the fluorescent non-imprinted polymer NIP 0 / F value keeps rising, when the adsorption time is 50min, F 0 The value of / F basically...

Embodiment 3

[0046] To study the adsorption performance of the sensing material (such as Figure 9 , 10 shown), weighed 1mg of imprinted polymer MIP and non-imprinted polymer NIP, placed at the bottom of a 4mL centrifuge tube, and added 2mL of different concentrations (0.1mg L -1 , 2 mg L -1 , 4 mg L -1 , 6mgL -1 , 8mgL -1 , 10 mg L -1 , 12 mg L -1 , 14 mg L -1 , 16 mg L -1 , 18 mg L -1 , 20 mg L -1 ) of the standard solution of cis-cypermethrin-acetonitrile, each concentration was set to five parallels, then the centrifuge tube was sealed with a parafilm, fixed on a horizontal shaker at room temperature and fully oscillated for 50min, and then the fluorescence spectrophotometry was performed with an external 980nm exciter The fluorescence intensity of the two polymer materials before and after adsorption was measured by the instrument, and the adsorption equilibrium curves of the fluorescent imprinted polymer material and the non-imprinted polymer material were drawn respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com