Core-shell type fluorine-free waterproof finishing agent, and preparation method and application thereof

A fluorine-free waterproof, core-shell type technology, applied in fiber treatment, textiles and papermaking, liquid-repellent fibers, etc., can solve problems such as refractory and unsafe, and achieve good dynamic water repellency and excellent surface Performance, long-lasting and stable surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

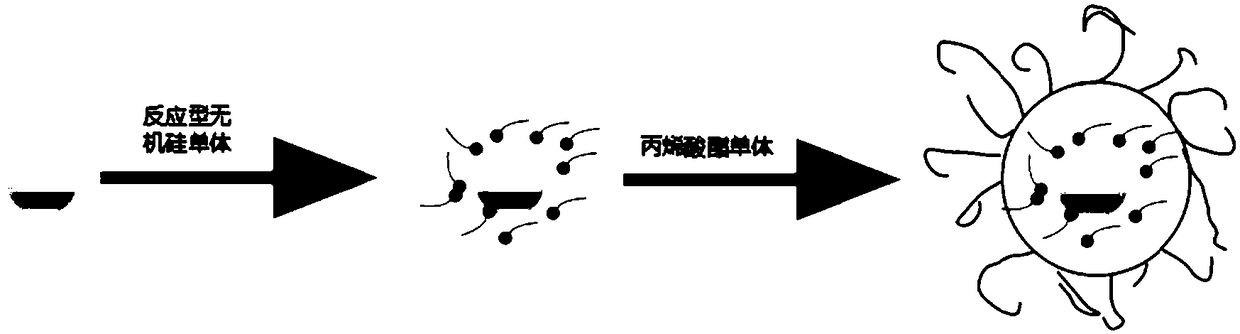

Method used

Image

Examples

Embodiment 1

[0087] Synthesis of Large Size Particles (I):

[0088] 1) Mix 125.0g absolute ethanol and 50.0g ammonia water at room temperature;

[0089] 2) Add 50.0 g of silicon dioxide, titanium dioxide or zinc oxide particles with a particle diameter of 50-500 nm to the mixed solution in 1), and ultrasonicate for 30 minutes.

[0090] 3) Add 0.5 g of vinyltrimethoxysilane and / or γ-methacryloxypropyltrimethoxysilane to the mixture of 2), and ultrasonicate for 120 minutes;

[0091] 4) The suspension obtained in 3) was filtered with a Buchner funnel, the filter cake was washed three times with deionized water and absolute ethanol and then filtered, and the obtained filter cake was dried at 120° C. to obtain large-diameter particles (I).

Embodiment 2

[0093] Synthesis of large particle size particle dispersion (II):

[0094] 100ml H 2 O. Mix 0.3g emulsifier 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether ammonium sulfate (DNS-86) and 0.10g NaOH into 100ml three Neck round bottom flask was stirred for 30min, then slowly added 15g KH-570 (3-(methacryloyloxy)propyltrimethoxysilane), and continued the reaction at room temperature for 24 hours, adjusted the temperature to 50°C and continued Stirring was carried out for 1 day to obtain a large-diameter particle dispersion (II).

Embodiment 3

[0096] Synthesis of Reactive Inorganic Silicon Monomer (I):

[0097] 1) Mix 125.0g absolute ethanol and 50.0g ammonia water at room temperature;

[0098] 2) Add 50.0 g of silicon dioxide nanoparticles with a particle size of 20 nm to the mixed solution of 1), and sonicate for 30 minutes;

[0099] 3) Add 0.1g of vinyltrimethoxysilane and 2.5g of dodecyltrimethoxysilane to the mixture of 2), and ultrasonicate for 120 minutes;

[0100] 4) Filter the suspension obtained in 3) with a Buchner funnel, wash the filter cake three times with deionized water and absolute ethanol and then filter, and dry the obtained filter cake at 120°C to obtain the reactive inorganic silicon monomer (I) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com