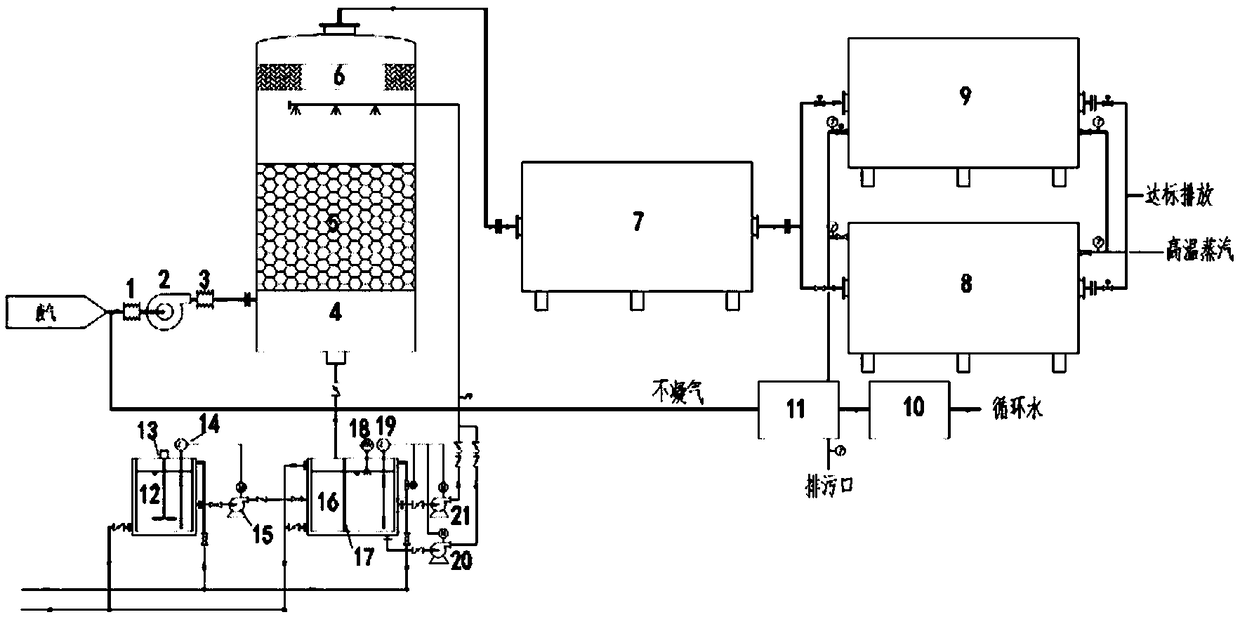

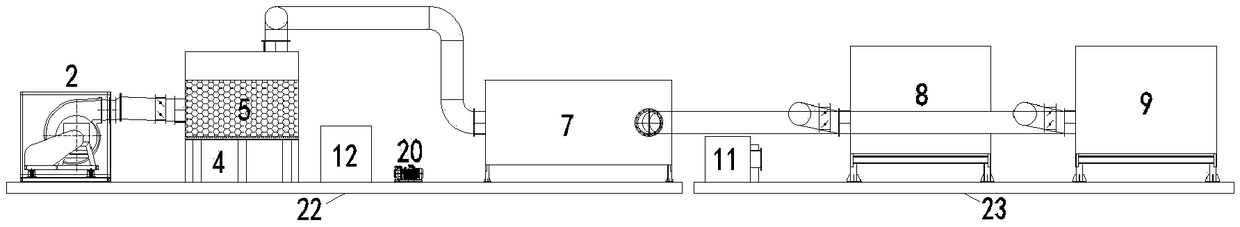

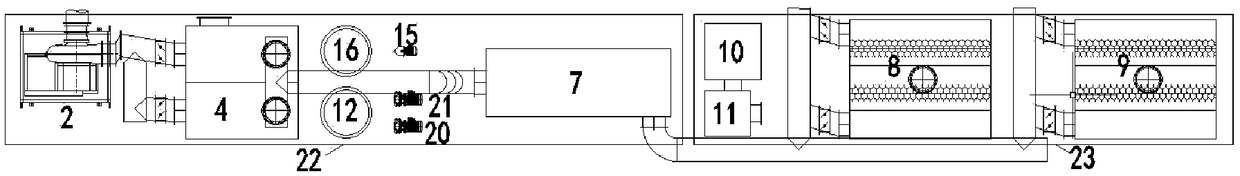

Device and method used for skid mounted module type processing of VOCs exhaust gas

A modular waste gas technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of low treatment efficiency, incomplete treatment, high cost, etc., achieve simple operation and maintenance, convenient vehicle transportation, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: Treating a certain medium-to-high concentration tail gas containing pollutants benzene, toluene, xylene, hydrogen sulfide, ammonia and methyl mercaptan, the gas flow rate is 2500Nm 3 / h; Spray treatment with lye diluted with 5% NaOH, the temperature of the spray chamber is normal temperature (25°C), and the normal pressure operation, the tail gas after spraying is passed into the biological trickling filter treatment device (the biological strain is the existing There are mature products), enter the adsorption device after biochemical treatment, the temperature of the adsorption device is 25°C, the adsorption pressure is 110KPa, and it is filled with ordinary activated carbon (the activated carbon filtration wind speed is 0.35m / s, the effective residence time of the gas in the activated carbon is 0.6s, and the iodine value of the activated carbon is 800m / s g, moisture content 2%, specific surface area 750m 2 / g, hole density 100 holes / m 2 , true specific ...

Embodiment 2

[0080] Embodiment 2: Treat a tail gas with a pollutant concentration of about 1%, and the gas flow rate is 2500Nm 3 / h; do pre-spray treatment with lye diluted with 5% NaOH, the temperature of the spray chamber is normal temperature (25°C), and the normal pressure operation, the tail gas after spraying is passed into the biological trickling filter treatment device (biological strain It is an existing mature product), after biochemical treatment, it enters the left and right chambers of the improved adsorption device of this patent. The effective residence time of activated carbon is 1.15s, the iodine value of activated carbon is 1000m / g, the moisture content is 1%, and the specific surface area is 1000m 2 / g, hole density 200 holes / m 2 , true specific gravity 2g / cm 3 , bulk specific gravity 0.4g / cm 3 ), the resulting process results are shown in Table 2:

[0081] Table 2 process results

[0082]

[0083] This example is a comparative example, which adopts the existing...

Embodiment 3

[0084] Embodiment 3: Treat a tail gas with a pollutant concentration of about 1%, and the gas flow rate is 5000Nm 3 / h; do pre-spray treatment with lye diluted with 5% NaOH, the temperature of the spray chamber is 15°C, the pressure is 101Kpa, and the tail gas after spraying is passed into the ultraviolet lamp catalytic oxidation device (30 ultraviolet light tubes are filled, 150W / piece), after being catalyzed by ultraviolet light, it is passed into the left and right chambers of the adsorption device. The temperature of the adsorption device is 15°C, the adsorption pressure is 101KPa, and it is filled with high-performance improved activated carbon (the wind speed of activated carbon filtration is 0.26m / s, and the gas is effective in activated carbon. The residence time is 1.15s, the iodine value of activated carbon is 1000m / g, the moisture content is 1%, and the specific surface area is 1000m 2 / g, hole density 200 holes / m 2 , true specific gravity 2g / cm 3 , bulk specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com