Manganese activated amorphous iron-based adsorption agent preparation method

An adsorbent, iron-based technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as high environmental sensitivity, poor material stability, and difficult solid-liquid separation, and achieve the cost of preparation The effect of low, strong stability, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The effect of the mass ratio of sodium hydroxide and montmorillonite powder on the removal of hexavalent chromium, pentavalent arsenic and pentavalent antimony ions in water:

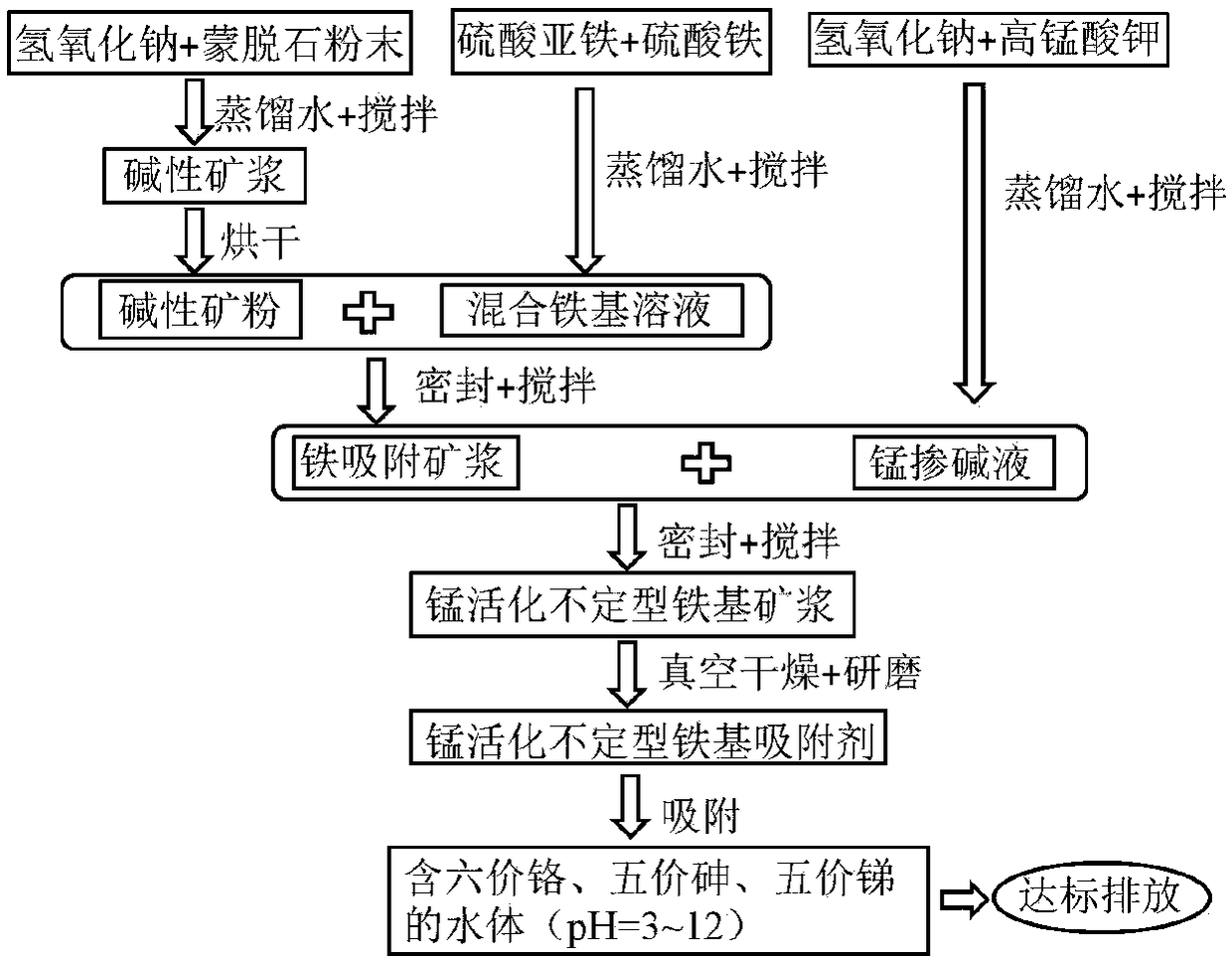

[0030] like figure 1 Shown, is the preparation process of manganese-activated amorphous iron-based adsorbent, specifically:

[0031] (1) Preparation of alkaline pulp: weigh sodium hydroxide and montmorillonite powder respectively according to the mass ratio of 0.75:10, 1.0:10, 1.25:10, and 1.5:10, dissolve in distilled water, and stir for 20 minutes at 30 rpm;

[0032] (2) Preparation of alkaline ore powder: place the alkaline ore slurry in an oven and dry at 100°C to constant weight;

[0033] (3) Preparation of mixed iron-based solution: take ferrous sulfate and ferric sulfate respectively by weighing ferrous sulfate and ferric sulfate according to the mol ratio of Fe(II) of ferrous sulfate and Fe(III) of ferric sulfate to 3:1, press ferrous sulfate and sulfuric acid The solid-to-liquid ratio ...

Embodiment 2

[0043] The effect of the molar ratio of Fe(II) to Fe(III) on the removal of hexavalent chromium, pentavalent arsenic and pentavalent antimony ions in water:

[0044] Preparation process is with embodiment 1, and embodiment 1 difference is:

[0045] (1) Preparation of alkaline pulp: the mass ratio of sodium hydroxide and montmorillonite powder is 1.5:10, dissolved in distilled water, stirred for 15min at 40rpm;

[0046] (2) Preparation of alkaline ore powder: drying the alkaline ore pulp in an oven at 125°C;

[0047] (3) Preparation of mixed iron-based solution: the molar ratios of Fe(II) to Fe(III) are 3:1, 3.5:1, 4:1, 4.5:1, 5:1, ferrous sulfate and ferric sulfate The solid-to-liquid ratio of the total mass of distilled water to 2.5g:10mL;

[0048] (4) Preparation of manganese-doped lye: OH - The molar ratio to Fe(II)+Fe(III) is 2.5:1, and the mass ratio of potassium permanganate to alkaline mineral powder is 5.5:100;

[0049] (5) Preparation of iron-adsorbed pulp: the so...

Embodiment 3

[0057] Oh - The influence of the molar ratio of Fe(II)+Fe(III) on the removal of hexavalent chromium, pentavalent arsenic and pentavalent antimony ions in water:

[0058] Preparation process is with embodiment 1, and embodiment 1 difference is:

[0059] (1) Preparation of alkaline pulp: the mass ratio of sodium hydroxide and montmorillonite powder is 1.5:10, dissolved in distilled water, stirred for 10min at 50rpm;

[0060] (2) Preparation of alkaline ore powder: drying the alkaline ore pulp in an oven at 150°C;

[0061] (3) Preparation of mixed iron-based solution: the molar ratio of Fe(II) to Fe(III) is 4.5:1, and the solid-liquid ratio of the total mass of ferrous sulfate and ferric sulfate to distilled water is 3g:10mL;

[0062] (4) Preparation of manganese-doped lye: OH - The molar ratios to Fe(II)+Fe(III) are 2:1, 2.25:1, 2.5:1, 2.75:1, 3:1 respectively, and the mass ratio of potassium permanganate to alkaline mineral powder is 10:100;

[0063] (5) Preparation of iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com